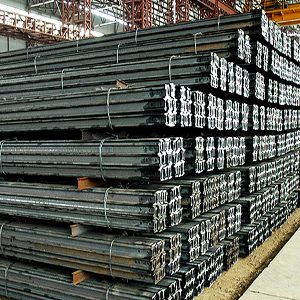

AREMA 90 ARA-A steel rail

$850.00 $800.00

Standard: AISI, ASTM, JIS

Grade: 900A/1100

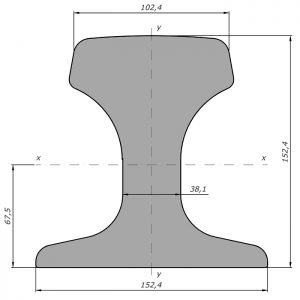

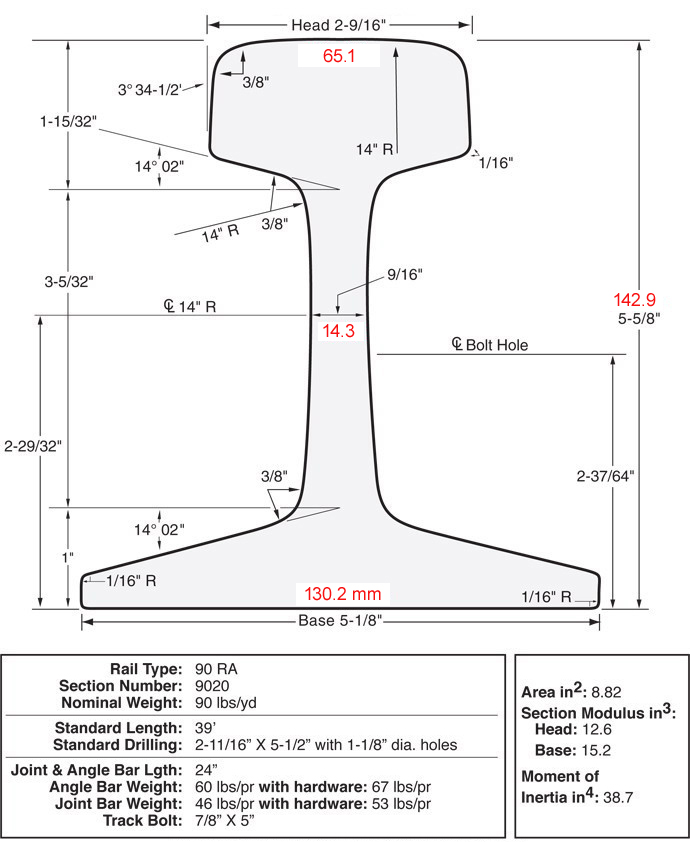

Rail Heigth: 142.9mm

Bottom Width: 130.2mm

Web Thickness: 14.3mm

Head Width: 65.1mm

Length: 12-30m

Model Number: TR45 (90 ARA-A)

Type: Heavy Rail

Application: Railway Rail

Weight: 44.64 kg/m

Name: AREMA 90 ARA-A rail

Usage: Factory railroad line

Market: South America

Certificate: 3.1 MTC/EN 10204, 3.2 by Lloyd’s regiester inspection

MOQ: 400 Tons

Warranty: 12 months

HS CODE: 73021000

Supply Ability: 4500 Ton/Tons per Day

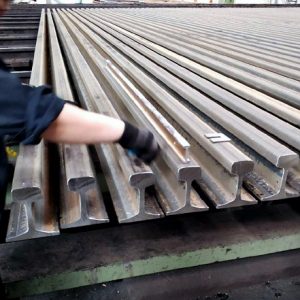

Packaging Details: Bundle by bulk cargo

Port: Tianjin port

- Description

- Exportable international standard flat bottom rail

- Producing and Inspection standard

- Inquiry

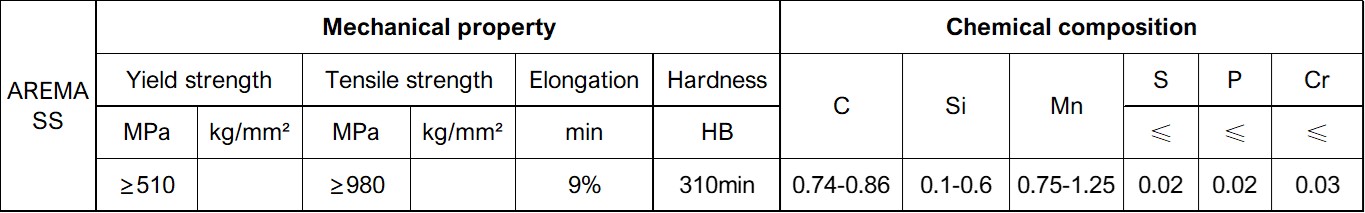

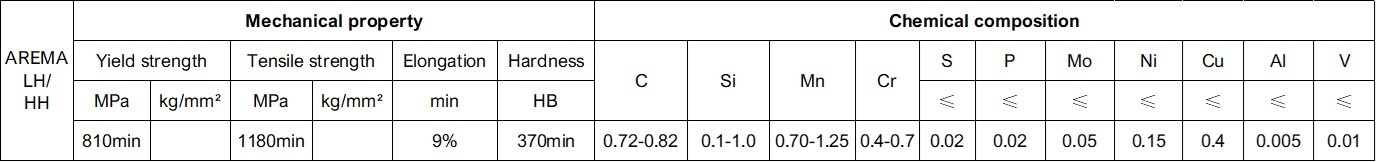

AREMA 90 ARA-A steel rail is used for Americas area, we can produce it by order, the MOQ is 500 tons, length 12-25m, material SS or HH.

Drawing of AREMA 90 ARA-A steel rail

The AREMA 90 ARA-A steel rail is a type of railroad track that is widely used in the United States. This rail meets the standards set forth by the American Railway Engineering and Maintenance-of-Way Association (AREMA), which is an industry group that establishes technical specifications for railway infrastructure.

The 90 ARA-A steel rail is a type of heavy-duty track designed to withstand the high loads and stresses associated with freight trains. It is typically used in mainline track applications where heavy traffic volumes and high speeds are common. The rail is manufactured from high-quality steel, which provides excellent strength and durability.

The rail profile is designed to maximize stability and minimize wear and tear. The bottom of the rail is shaped like an inverted T, which provides a wide base for stability and helps distribute the weight of the train more evenly across the track. The top of the rail has a flat surface that provides a smooth ride for the train wheels.

The AREMA 90 ARA-A steel rail is available in various lengths and weights to suit different applications. It is typically installed using a series of spikes or bolts that hold the rail in place. The rail is also designed to be compatible with a range of other track components, including rail joints, tie plates, and fastening systems.

One of the key advantages of the AREMA 90 ARA-A steel rail is its durability. The rail is designed to last for many years with minimal maintenance, making it a cost-effective choice for railway operators. The rail is also resistant to wear and tear, which helps reduce the need for expensive repairs and replacements.

In addition to its durability, the AREMA 90 ARA-A steel rail is also designed for safety. The rail profile and fastening systems are engineered to provide a stable and secure foundation for trains to travel on. This helps reduce the risk of derailments and other accidents, which can be costly both in terms of human life and financial resources.

Overall, the AREMA 90 ARA-A steel rail is an important component of railroad infrastructure in the United States. It is designed to meet the high demands of heavy freight traffic and is engineered for durability and safety. Railway operators can rely on the AREMA 90 ARA-A steel rail to provide a stable and secure foundation for their trains, ensuring reliable and efficient transportation of goods across the country.

Standard EN 13674 - 1:2003 consists of two main parts:

− qualification test and acceptance tests

Qualification tests are some other tests that were previously carried out, as for example, fracture toughness. Acceptance tests characterize the properties of the prescribed tests, which ensure production of high quality rails, and testing requirements of railway administration.

Quality of rails is based on measured values of hardness, by which they introduced new labels for steel rails.

Qualifying tests

Qualification testing must be conducted at least one in five years and the major

changes in technology, production rails. Additional testing residual stresses are carried

out on all types of steel rails every two year maximum, provided that the longitudinal

strain rate in the rails can amount to up to 250 MPa.

The prescribed qualifying examination is the following:

− fracture toughness

− fatigue crack growth rate

− fatigue testing

− residual stress in rail foot

− variation of centre line

− tensile strength and elongation

− segregation

− other qualification requirements

Acceptance tests

Within acceptance testing is carried out a series of laboratory tests such as:

− chemical composition (the maximum content of the following elements: H, O, Al, V, N and oligo elements)

− microstructure (increasing x 500)

− degree of decarburizing charred layer (allowed up to 0.25 mm)

− purity of steel (especially the presence of oxide)

− macrostructure (Baumann test)

− hardness

− tensile strength

Other acceptance testing rails are:

− dimension tolerances

− criteria (control template)

− inspection requirements / tolerances for to internal quality and surface quality

Internal state is examined ultrasound in a continuous process control, and includes at least 70% of the head and at least 60% web.

- Standard of UIC 860 V: 1996 - prescribed four types pearlite steel rails in the range of tensile strength from 700 to 1300 MPa.

- Standard EN 13674 - 2003, provides seven types pearlite steel hardness in the range 200 to 390 HBV, types steel in accordance with EN 13674, based on the values of hardness (R 200, R 220, R 260, R 260 Mn, 320 Cr, 350 HT, 350 LHT).