BS113A steel rail

$800.00 $750.00

Standard: BS, DIN

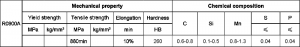

Grade: 900A, min 880 N/mm2

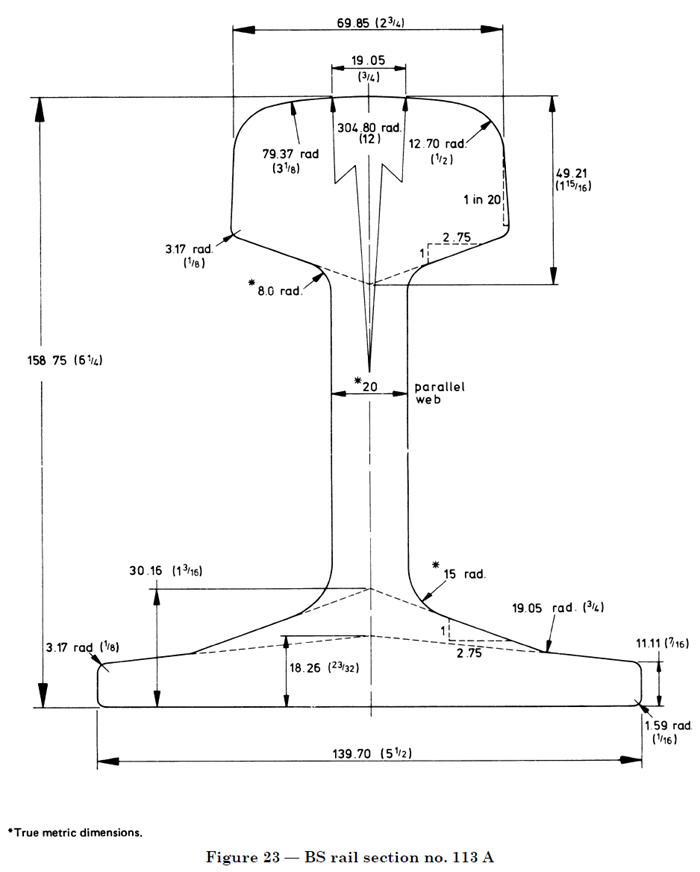

Rail Heigth: 158.75mm

Bottom Width: 139.7mm

Web Thickness: 20mm

Head Width: 69.85mm

Length: 8-25m

Model Number: BS113A rail

Type: Heavy Rail

Application: Railway Rail

Weight: 56.4kg/m

Secondary Or Not: Non-secondary

Bolt Hole Diameter: 24mm

Tolerance: ±2%

Name: BS11-1985 standard BS113A train metal steel rail

Certificate: MTC 3.1/EN 10204 3.2

Producing standard: UIC860V

MOQ: 3000 Tons

Warranty: 12 months

HS CODE: 73021000

Advantage: Competitive Prices

Material: 900A

Package: Bundle to container or bulk cargo

Supply Ability: 5000 Ton/Tons per Day

Packaging Details: Bundle to container or bulk cargo

Port: Tianjin port

- Description

- Q & A

- Our Exportable flat bottom rails:

- Inquiry

BS113A steel rail is used for mining railroad line or metro etc. The material is 900A, hardness is more than 880 N/mm2, length can be 8-25 meters, please contact us to ask the details.

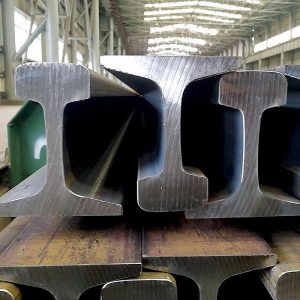

BS113A steel rail is a British Standard that specifies the requirements for flat-bottomed railway rails. The standard covers various aspects of rail design, manufacture, testing, and inspection, including material properties, dimensions, tolerances, and surface finish.

The BS 113A standard defines several types of flat-bottomed railway rails, each with specific characteristics suitable for different applications. However, BS113A steel rail is not normal type of rail.

BS113A steel rail refer to a particular type of rail that conforms to the requirements specified in the BS 113A standard. In this case, the rail would have a flat bottom and be manufactured from high-quality steel, typically carbon-manganese or other alloy steels, that meet the mechanical property requirements outlined in the standard.

According to the BS 113A standard, the rail must meet specific requirements for dimensions, tolerances, and mechanical properties, including yield strength, ultimate tensile strength, elongation, and hardness. These requirements ensure that the rail can withstand the stresses and wear associated with heavy freight and passenger traffic on railway networks.

Compliance with the BS 113A standard ensures that the rail meets the highest quality and safety standards for railway infrastructure in the United Kingdom and other countries that adopt this standard. This makes it a trusted choice for railway operators and infrastructure managers who require reliable and interoperable rail components for their networks.

Overall, BS113A steel rail provides valuable guidance for engineers and practitioners involved in the design, construction, and maintenance of railway track infrastructure, including the selection and use of appropriate steel rail materials and components.

Introduction of our manufacturer:

Rolling machine:

Why the quality of our steel rail is very good?

- Because we control the producing process since steel melting.

(1) Rail was produced by very specialized process.

(2) Liquid iron will be desulfurization before steel marking.

(3) Slag stoppers are used in tapping operation to eliminate or minimize the carryover of slag into the steel ladle.

(4) The steel ladle will be stirred by argon in the bottom for liquid steel temperature homogenized, steel composition uniformed and removal of nonmetallic inclusions.

(5) On the top of ladle add insulating slag as precaution after tapping.

(6) Steel temperatures, chemical compositions and deoxidation practices can be controlled more precisely by second refining. Vacuum degassing is used for removing gases such as hydrogen, oxygen and nitrogen. Improve the purity of steel through removing oxygen and removing nonmetallic inclusions by flotation.

(7) Avoid second oxidation in continuous casting through in-ladle slag carryover predication, protective casting, tundish metallurgy and mould level automatic control.

(8) Improve the surface quality and segregation through control the constant casting speed, in-mould electromagnetic stirring, dynamic control of secondary cooling and soft reduction in final stage.

(9) Rolling by Universal mill and right designing to ensure the better profile and tolerance.

(10) Two times descaling will be used to improve rail surface quality.

(11) The independent drive prebend device is used to prebend the rail reliably and remove the bending rail safely during the cooling process to reduce the residual stress.

(12) All rail shall be straightened and ultrasonically tested by a continuous process to ensure whole of rails length and specified cross sectional area are inspected fully.

- Arrange quality control plan according to technical specification and contract before production.

- Inspection and Test Plan shall be arranged as per the technical specification and contract before production.

- Mill’s Certificate: Products can’t be sold and dispatched from the factory if it is not qualified.

- Shipment: The rail will be delivered by railway or truck according to different length.

- Loading and unloading shall use special rail clamp, to avoid the head of rail damage.

- Loading plan shall be arranged before loading according to different vessel to ensure quality and safety of the goods.

Q: What's included in the service range and what is your core value?

A: Our service mainly refers to quality products, competitive price and good service for resourcing, inspection, shipment loading, and installation guidance.

Our core value is “Good product, good price, good service.”

Q: What's your offer validity period?

A: This will be decided by steel price, exchange rate and sea freight charge, normally we can keep 10 days for you, but sometime will be changed a few days. If you want to place the order, please confirm it again.

Q: What is your terms of payment?

A: T/T 30% in advance, the balance against the copy of bill of lading, or 100% irrevocable letter of credit at sight. We'll show you the photos of the products and packages before you pay the balance.

Q: What is your terms of delivery?

A: FOB, CFR, CNF, CIF, DDP, EXW and so on.

Q: How about your delivery time?

A: Generally, it will be 10-15 days after receiving your advance payment. Some type of rail should be produced by order, we will tell you the delivery time when we make the quotation for you. If we use bulk cargo, the shipping time will be very freely, but the cost is cheaper, this only for bulk goods.

Q: Can you produce according to the our special request?

A: Yes, we would like to do it, but should confirm the quantity, and confirm whether we have this roller, please tell us your request first, let's confirm the details.

Q: What is the guarantee of the quality of your products?

A: Normally should be 12 months, for special railway rail, we can submit the guarantee of five year plus.

All of our goods can accept any third party inspection.

Q: How do you make our business long-term and good relationship?

A: We maintain good quality and competitive prices in order to achieve a win-win cooperation. We will supply the correct products and make the process smoothly by our rich experience, even face any problem in the process, we will be able to solve it successfully.