DIN536 A55 crane rail

$1,000.00 $980.00

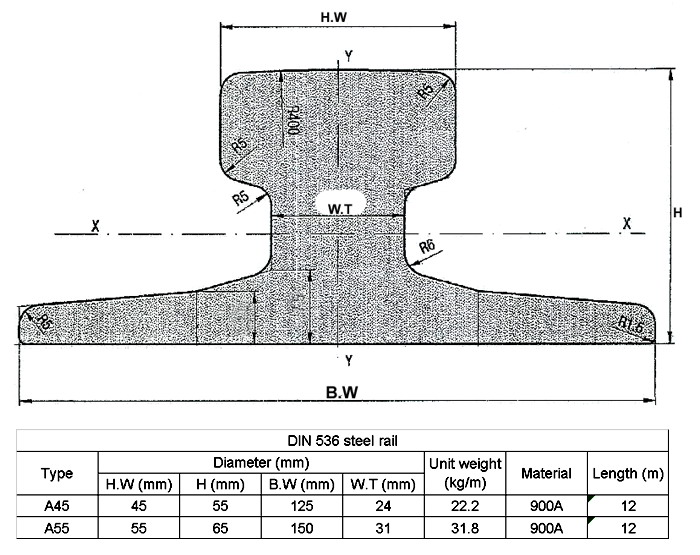

- Standard: DIN

- Grade: 900A

- Rail Heigth: 65mm

- Bottom Width: 150mm

- Web Thickness: 31mm

- Head Width: 55mm

- Length: 12m

- Model Number: A55

- Application: Crane running rail

- Weight: 31.8 kg/m

- Name: DIN536 Crane rail

- Product name: A55 Crane rail

- Usage: For crane runing

- Certificate: Certificate of quality 3.1

- Market: English countries

- MOQ: 20 Ton/Tons

- Warranty: 12 months

- Advantage: Wide bottom

- HS CODE: 73021000

- Description

- Exportable flat bottom rail

- Inquiry

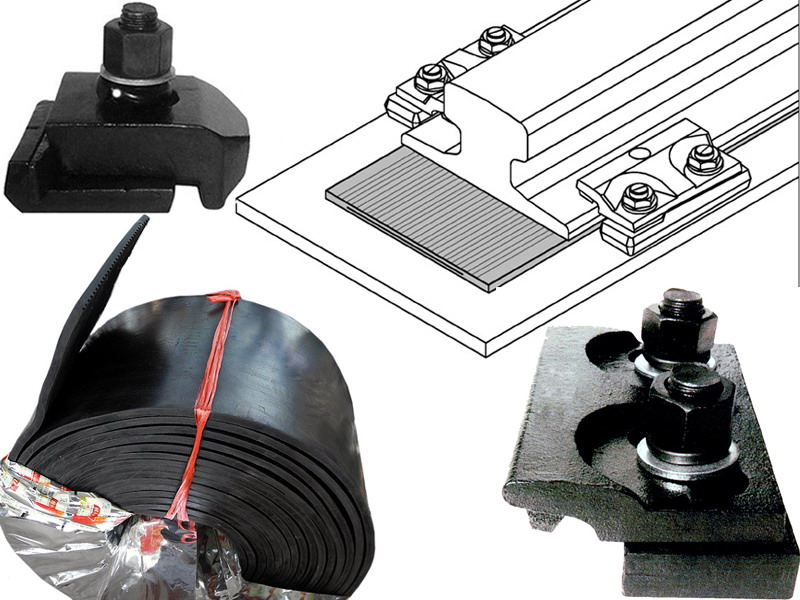

DIN536 A55 crane rail is used for light crane running line, we can supply it and all of the fasteners as below:

HS Code Description

73021000 A55 Crane rail, Material 700 A, Length 12 meters, Unit weight 31.8 kg/m

85479090 Rubber pad, 7*150*12000 mm

86080090 Double weld rail clamp, Distance 0.5/0.6 m

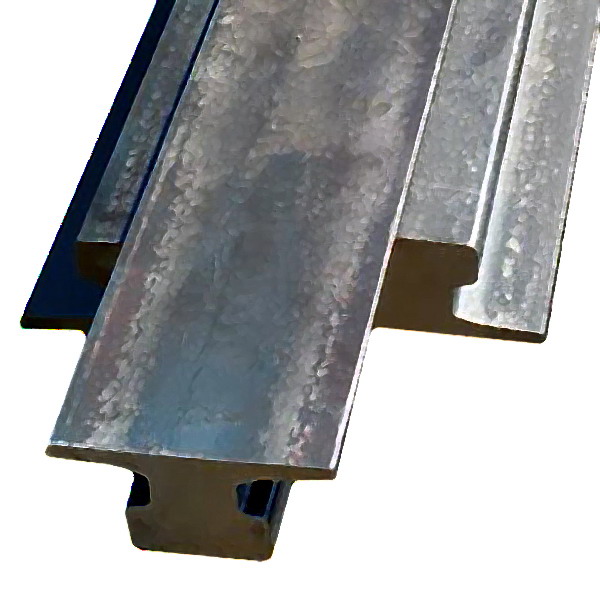

Drawing of DIN536 A55 crane rail

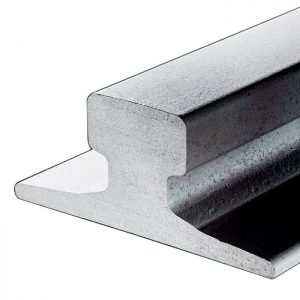

DIN536 A55 crane rail is a type of heavy-duty rail that adheres to the German Institute for Standardization (DIN) specifications. It is commonly used in Europe and other regions where DIN standards are followed for crane and lifting applications.

The DIN536 A55 crane rail has a weight of 55 kilograms per meter and features a unique profile that is optimized for use in cranes, hoists, and other lifting equipment. It has a height of 176 millimeters, a base width of 149 millimeters, and a head width of 89 millimeters. The rail also has a web thickness of 16 millimeters and a flange thickness of 25 millimeters.

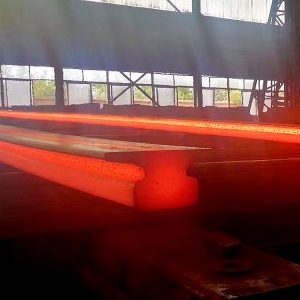

One of the key advantages of the DIN536 A55 crane rail is its high load-bearing capacity. It is designed to withstand extremely heavy loads and frequent use, making it ideal for use in ports, shipyards, steel mills, and other industrial settings where heavy loads need to be lifted and moved on a regular basis. The rail is made from high-quality steel that undergoes rigorous manufacturing processes to ensure optimal mechanical properties and durability.

In addition to its high strength and load-bearing capacity, the DIN536 A55 crane rail is also designed with safety in mind. It features a continuous welded structure that minimizes the risk of rail breaks or derailments, and it is equipped with special fittings such as fishplates, bolts, and clips that ensure a secure connection between the rails and prevent movement or displacement.

The DIN536 A55 crane rail is easy to install and maintain, thanks to its standardized dimensions and fittings. It can be installed using a variety of methods, including direct fixing, clamping, or welding, depending on the specific requirements of the application.

To ensure the quality and reliability of the DIN536 A55 crane rail, it undergoes rigorous testing and certification processes before being approved for use. These tests include tensile strength tests, impact tests, and fatigue tests, among others, to verify the rail’s mechanical properties and performance under different operating conditions.

The DIN536 A55 crane rail is widely used in Europe and other regions where DIN standards are followed for crane and lifting applications. However, it can also be used in other countries where similar rail profiles are used, provided that the necessary adaptations are made to the rail infrastructure.

In conclusion, the DIN536 A55 crane rail is a high-performance railway track that is specifically designed for use in cranes, hoists, and other lifting equipment. Its high load-bearing capacity, strength, durability, and safety features make it an ideal choice for industrial settings where heavy loads need to be lifted and moved regularly. As a supplier of railway track products, we offer a range of high-quality DIN536 A55 crane rails and related components to meet the needs of our customers. If you require more information or would like to request a quote, please do not hesitate to contact us.