Marine steel plate

$1,300.00 $1,100.00

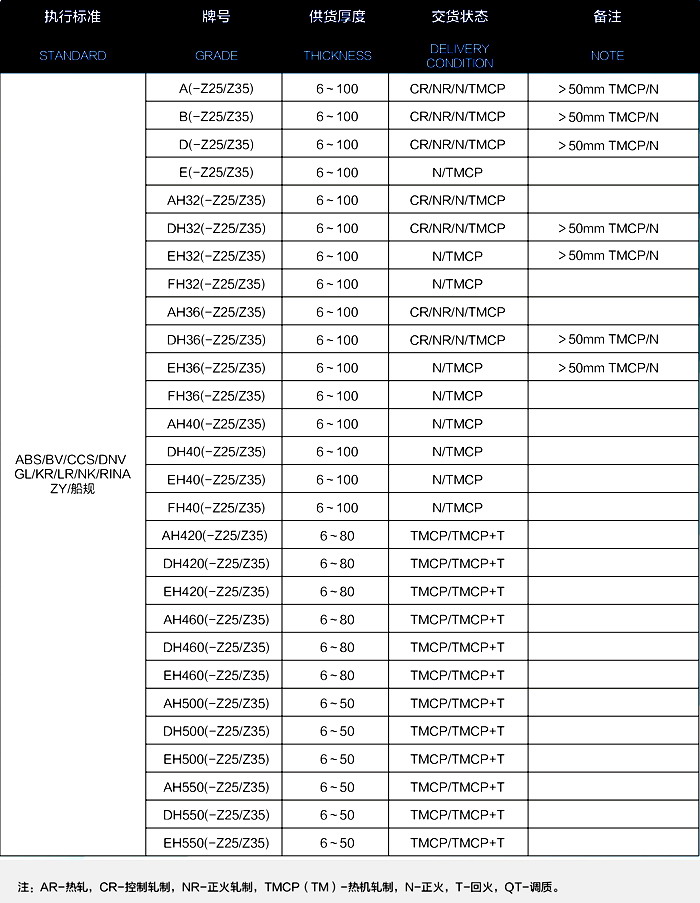

Standard: CCS

Grade: 2C, 3C, 4C, 5C, 12MNC, 16MNC, 15MnTiC, 14MnVtirec

Place of Origin: Liaoning, China

Brand Name: Yueqi

Model Number: A B D E AH32 AH36 DH32 DH36 EH32 EH36

Type: Steel Plate, Low-Alloy Plate

Technique: Hot Rolled

Surface Treatment: Sand blasting and Primer

Application: Ship Plate

Special Use: High-strength Steel Plate

Width: 2000mm-2500mm

Length: 6000mm-12000mm

Tolerance: ±2%

Processing Service: Bending, Welding, Cutting, Punching

Delivery Time: 45 days

Product Name: Marine steel plate

Normal Material steel grade: Mild Steel ABS GR.A B D E

Normal material: 2C, 3C, 4C & 5C

Hi strength material steel grade: AH32 AH36 DH32 DH36 EH32 EH36

Hi strength material: Low alloy steel 12MnC, 16MnC, 15MnTiC, 14MnVTiReC

Usage: used for shipbuilding and the manufacture of ship’s hull structure

MOQ: 300 tons

Advantage: Competitive price and good quality

Edge: 4 cutting

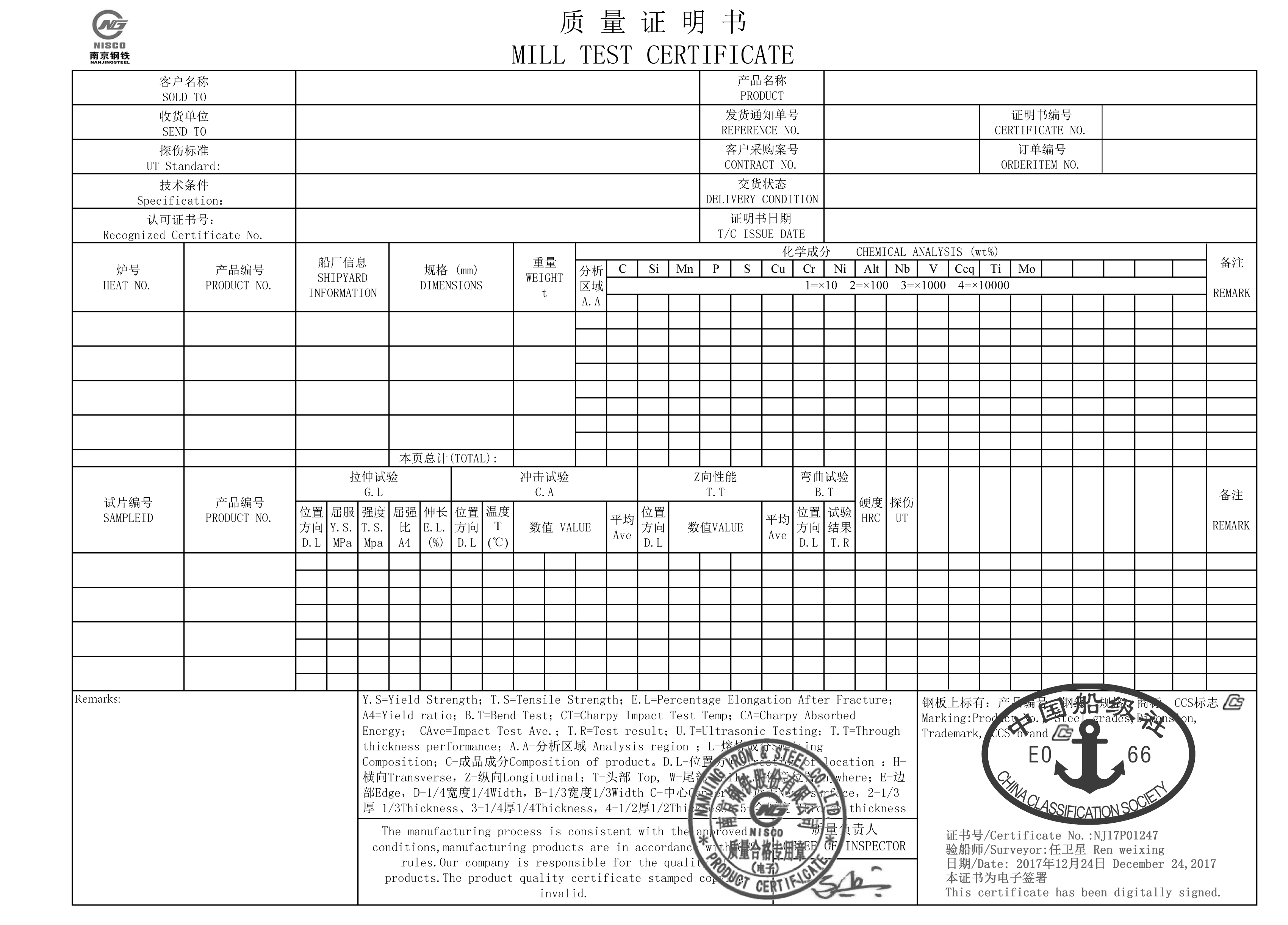

Certificate: Class certification material certificates

Supply Ability: 3000 Ton/Tons per Day

Packaging & Delivery

Packaging Details: Bundle in container or bulk cargo

Port: Tianjin port

Lead Time: To be negotiated

- Description

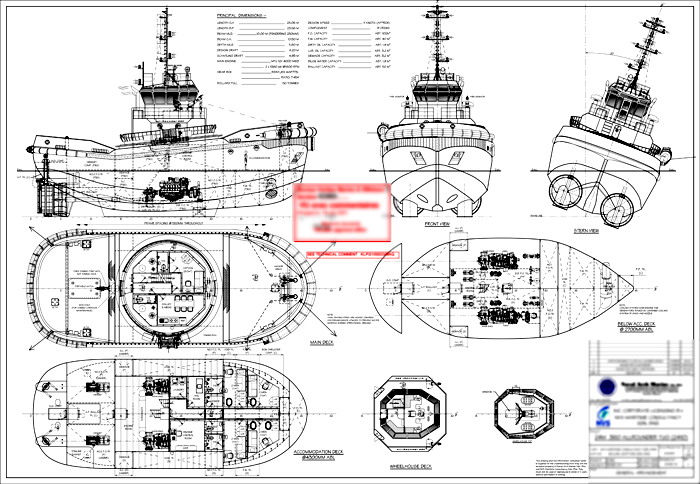

- Sample of the shipbuilding materials for a 25m length boat

- Inquiry

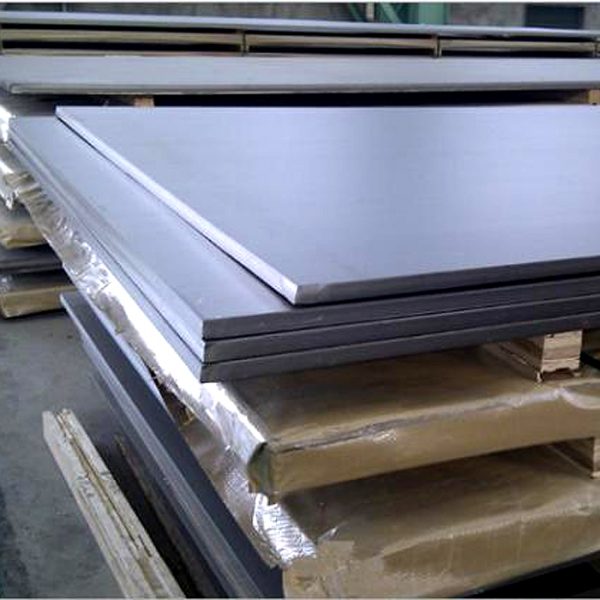

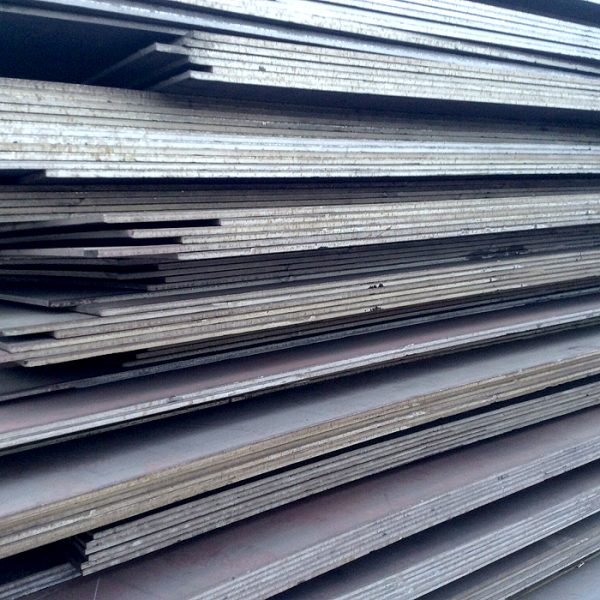

Marine steel plate also be named Marine hull structure mild steel plate, it has thin and thick steel plate that was made by structural steel, it is specially used for shipbuilding and used for the manufacture of ship’s hull structure for ocean-going, coastal and inland river navigation.

Structural steels for shipbuilding includes carbon steel and low alloy steels that marked C at the end of steel number. Carbon steels include 2C, 3C, 4C and 5C, and low alloy steels include 12MNC, 16MNC, 15MnTiC, 14MnVtirec and other steels.

Available type of Marine steel plate

Usage of Marine steel plate

MTC 3.1 certificate of Marine steel plate

Marine steel plate refers to a type of steel plate specifically designed and manufactured for use in the construction of marine structures, such as ships, offshore platforms, and other maritime applications. This type of steel plate is engineered to withstand the harsh conditions of the marine environment, including exposure to seawater, salt spray, and extreme temperatures.

Marine steel plate is typically made from high-quality carbon-manganese steel, with varying levels of alloying elements such as nickel, chromium, and molybdenum added to enhance its mechanical properties. The most common grades of marine steel plate include:

1. Ordinary Strength Hull Structural Steel: This grade of steel is used for general-purpose shipbuilding applications and has a minimum yield strength of 235 MPa.

2. High-Strength Hull Structural Steel: This grade of steel is used for more demanding shipbuilding applications and has a higher minimum yield strength than ordinary strength steel, typically ranging from 275 to 460 MPa.

3. Offshore Structural Steel: This grade of steel is used for the construction of offshore platforms and other marine structures that are subject to extreme loads and environmental conditions. It has a higher minimum yield strength than high-strength hull structural steel, typically ranging from 390 to 690 MPa.

Marine steel plate is typically produced using a hot-rolling process, which results in a uniform and consistent material with excellent dimensional stability. It is available in a range of thicknesses and widths to meet the specific requirements of different marine applications.

In addition to its strength and toughness, marine steel plate also offers good weldability, formability, and corrosion resistance. However, additional coatings or treatments may be applied to further enhance its durability and lifespan in saltwater environments.

Overall, marine steel plate is a critical component in the construction of marine structures, providing the necessary strength, toughness, and durability to withstand the rigors of the marine environment. Its reliable performance and cost-effectiveness make it a popular choice among shipbuilders and offshore engineers worldwide.

| Description | Thickness (mm) | Quantity (pcs) | Weight (T) | Unit wt. (kg/pc) |

| Plate, Mild steel ABS GR.A, 2438x9144mm, Marine grade with Class certification material certificate |

6 | 12 | 12.60 | 1,050 |

| 8 | 52 | 72.80 | 1,400 | |

| 9 | 21 | 33.08 | 1,575 | |

| 10 | 25 | 43.75 | 1,750 | |

| 12 | 29 | 60.90 | 2,100 | |

| 14 | 19 | 46.55 | 2,450 | |

| 16 | 2 | 5.60 | 2,800 | |

| 20 | 4 | 14.00 | 3,500 | |

| 25 | 1 | 4.38 | 4,375 | |

| 30 | 1 | 5.25 | 5,250 | |

| Grade ABS AH36 with sand blasting and Primer | 60 | 2 | 21.00 | 10,500 |

| TOTAL | 168 | 319.90 | ||

| Flat bar, Mild steel ABS GR.A, length 6m. Marine grade with Class certification material certificate |

150x12 | 18 | 1.53 | 84.78 |

| 125x12 | 4 | 0.28 | 70.65 | |

| 100x12 | 105 | 5.93 | 56.52 | |

| 100x9 | 9 | 0.38 | 42.39 | |

| 75x10 | 5 | 0.18 | 35.33 | |

| 75x9 | 2 | 0.06 | 31.79 | |

| 75x6 | 18 | 0.38 | 21.20 | |

| Angle bar, Mild steel ABS GR.A, length 6m. Marine grade with Class certification material certificate |

100x80x8 | 138 | 54.15 | 65.40 |

| 75x75x7 | 7 | 2.01 | 47.88 | |

| 75x50x6 | 12 | 2.46 | 34.20 | |

| 125x80x8 | 4 | 1.81 | 75.60 | |

| TOTAL | 322 | 69.19 | ||

| GENERAL TOTAL | 389.09 | |||