TR30 steel rail

$700.00 $660.00

Standard: ASTM, BS, GB, JIS

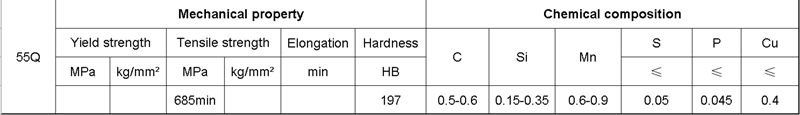

Grade: Q235B/55Q

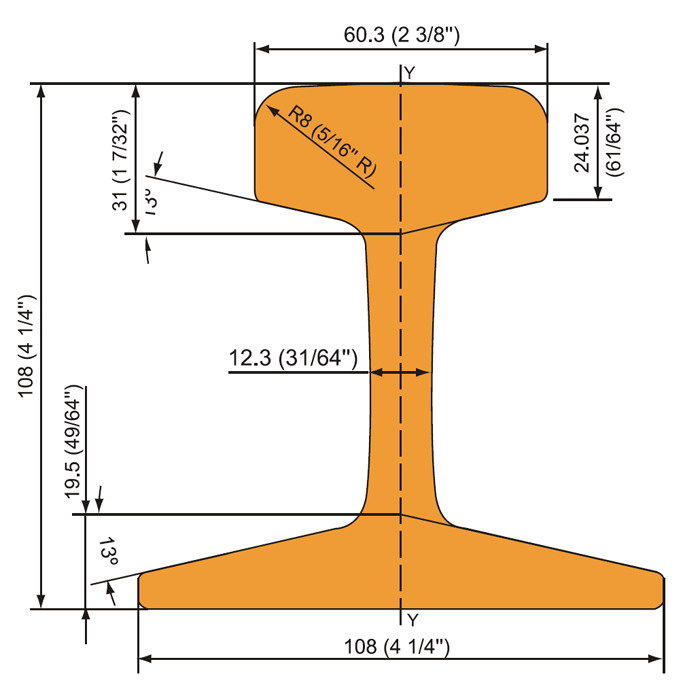

Rail Heigth: 108mm

Bottom Width: 108mm

Web Thickness: 12.3mm

Head Width: 60.33mm

Length: 6m/8m/10m

Place of Origin: Hebei, China (Mainland)

Brand Name: Hangang

Model Number: TR30

Type: Light Rail

Application: Railway Rail

Weight: 30.1kg/m

Secondary Or Not: Non-secondary

Bolt Hole Diameter: 24mm

Name: TR30 America standard light steel rail

Product name: 30kg/m lignt steel rail

Other name: Mining rail

Flange height of center: 19.45mm

Height of head: 30.95mm

Market: Developing countries

Usage: Mine car running rail

Certificate: ISO9001:2008

Property: TR30 America standard light steel rail

MOQ: 20 Ton/Tons

- Description

- Producing and inspection standard

- Exportable international standard flat bottom rail

- Inquiry

TR30 steel rail is used for mine railroad line or light rail track, we always have this stock, can deliver it timely. The material has Q235 and 55Q, length 6m, 8m and 10m.

TR30 steel rail is a type of steel rail used in railway tracks. It is primarily used in light rail transit (LRT) systems and urban transportation networks. The “TR” in TR30 stands for “Transit Rail,” indicating its specific application in transit systems.

TR30 rail is designed to meet the requirements of light rail transit, which typically involves lower axle loads and slower train speeds compared to heavy rail systems. Here are some key characteristics and features of TR30 steel rail:

1. Profile: TR30 rail has a specific profile that conforms to industry standards. It is typically characterized by its head width, height, and base width, which determine its load-bearing capacity and compatibility with other rail components.

2. Weight: TR30 rail typically weighs around 30 kilograms per meter. Its relatively lighter weight allows for easier handling during installation and maintenance.

3. Material: TR30 rail is commonly made from high-quality steel, which provides excellent strength, durability, and resistance to wear and fatigue. The exact specifications of the steel composition may vary depending on regional and industry standards.

4. Installation: TR30 rail is installed on concrete sleepers or wooden ties using appropriate fastening systems, such as clips or spikes. The rail joints are secured to ensure a seamless track alignment and smooth train operations.

5. Applications: TR30 rail is specifically designed for light rail transit systems, including urban trams, streetcars, and light metro systems. It is suitable for tracks with lower traffic volumes and lighter trains.

6. Maintenance: Regular inspection and maintenance are essential for ensuring the safe and efficient operation of TR30 rail tracks. This includes monitoring wear and tear, replacing worn-out sections, and maintaining proper rail alignment.

TR30 steel rail offers several advantages for light rail transit systems. Its lighter weight makes it easier to handle during installation and maintenance activities. The rail’s design and material properties ensure a smooth and comfortable ride for passengers. Additionally, TR30 steel rail is designed to withstand the specific load and speed requirements of light rail transit, making it a reliable choice for urban transportation networks.

It’s worth noting that specific rail standards and specifications may vary between different countries and regions. Therefore, it is important to consult local rail authorities or industry guidelines for precise information on TR30 steel rail and its application in specific locations.

Standard EN 13674 - 1:2003 consists of two main parts:

− qualification test and acceptance tests

Qualification tests are some other tests that were previously carried out, as for example, fracture toughness. Acceptance tests characterize the properties of the prescribed tests, which ensure production of high quality rails, and testing requirements of railway administration.

Quality of rails is based on measured values of hardness, by which they introduced new labels for steel rails.

Qualifying tests

Qualification testing must be conducted at least one in five years and the major

changes in technology, production rails. Additional testing residual stresses are carried

out on all types of steel rails every two year maximum, provided that the longitudinal

strain rate in the rails can amount to up to 250 MPa.

The prescribed qualifying examination is the following:

− fracture toughness

− fatigue crack growth rate

− fatigue testing

− residual stress in rail foot

− variation of centre line

− tensile strength and elongation

− segregation

− other qualification requirements

Acceptance tests

Within acceptance testing is carried out a series of laboratory tests such as:

− chemical composition (the maximum content of the following elements: H, O, Al, V, N and oligo elements)

− microstructure (increasing x 500)

− degree of decarburizing charred layer (allowed up to 0.25 mm)

− purity of steel (especially the presence of oxide)

− macrostructure (Baumann test)

− hardness

− tensile strength

Other acceptance testing rails are:

− dimension tolerances

− criteria (control template)

− inspection requirements / tolerances for to internal quality and surface quality

Internal state is examined ultrasound in a continuous process control, and includes at least 70% of the head and at least 60% web.

- Standard of UIC 860 V: 1996 - prescribed four types pearlite steel rails in the range of tensile strength from 700 to 1300 MPa.

- Standard EN 13674 - 2003, provides seven types pearlite steel hardness in the range 200 to 390 HBV, types steel in accordance with EN 13674, based on the values of hardness (R 200, R 220, R 260, R 260 Mn, 320 Cr, 350 HT, 350 LHT).