DIN536 crane rail is a type of steel rail used in overhead crane tracks and gantry crane tracks. It is manufactured according to the DIN 536 standard, which specifies the dimensions, material properties, and tolerances for this type of rail. DIN536 crane rails have a wide base and a thick head, which provides good stability and support for heavy loads. They are typically made from high-strength steel and are available in various lengths and sizes to suit different applications. DIN536 crane rails are widely used in ports, shipyards, steel mills, and other heavy industries where heavy lifting and transportation are required.

DIN 536 standard specifies the requirements for three types of crane rails: A45, A55, and A65.

– A45 crane rail has a bottom width of 45mm, a height of 55mm, and a weight of 22.2kg/m. It is commonly used in light-duty cranes and monorails.

– A55 crane rail has a bottom width of 55mm, a height of 65mm, and a weight of 31.8kg/m. It is suitable for medium-duty cranes and gantry cranes.

– A65 crane rail has a bottom width of 65mm, a height of 75mm, and a weight of 43.1kg/m. It is used in heavy-duty cranes and high-capacity gantry cranes.

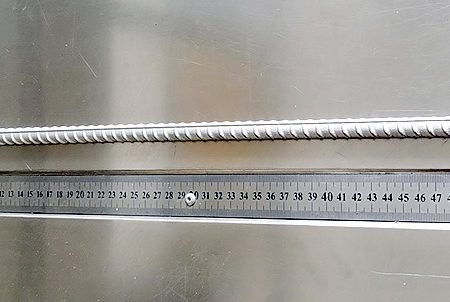

All three types of rails have a standard length of 12 meters and are made from high-strength steel with a minimum tensile strength of 690 MPa. They have a uniform profile and precise dimensions to ensure smooth and stable movement of crane wheels and trolleys.

– A75 crane rail: bottom width of 75mm, height of 85mm, weight of 56.2kg/m

– A100 crane rail: bottom width of 100mm, height of 95mm, weight of 74.3kg/m

– A120 crane rail: bottom width of 120mm, height of 105mm, weight of 100.2kg/m

– A150 crane rail: bottom width of 150mm, height of 150mm, weight of 150.3kg/m

These crane rails are used in heavy-duty cranes and high-capacity gantry cranes that require greater load capacity and stability. All of them have a standard length of 12 meters and are made from high-strength steel with a minimum tensile strength of 880 MPa.

The DIN 536 standard for crane rails is widely used in Europe, particularly in Germany, where the standard was developed. However, it is also recognized and used in other countries around the world, including China, India, South Africa, and some countries in the Middle East.

Crane rails manufactured to this standard have a uniform profile and precise dimensions, which ensures compatibility and interchangeability between different manufacturers and suppliers. This makes them a popular choice for heavy industries such as ports, shipyards, steel mills, and mining operations that require reliable and durable overhead crane tracks.

Welcome to ask us the international standard flat bottom rails as below: