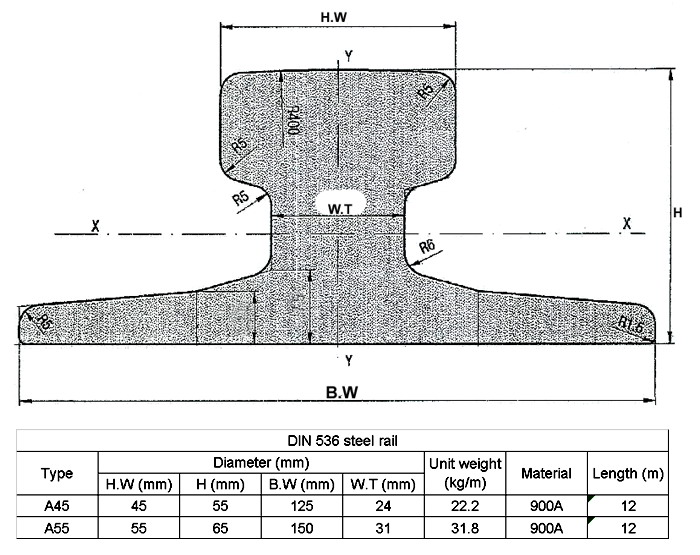

DIN 536 A55 crane rail is a type of steel rail designed specifically for use in overhead crane systems. The rail is named after the German Institute for Standardization (DIN) and its dimensions and specifications are in accordance with DIN 536 standards. The A55 designation refers to the rail’s weight per unit length, which is 31.8 kg/m.

A55 crane rail is our minimum DIN536 crane rail, we don’t produce A45 crane rail, only can use A55 instead of A45.

Crane rails provide a sturdy and reliable base for the wheels of cranes to move along, allowing for the efficient movement of heavy loads in factories, ports, and other industrial settings. The A55 crane rail features a wide, flat base and a slightly curved top surface, which provides a stable platform for the crane wheels to travel along, while also allowing for easy installation and maintenance. The rails are typically mounted onto concrete or steel supports, and can be cut to length to fit the specific requirements of the crane system. Overall, DIN 536 A55 crane rails are a durable and cost-effective solution for heavy-duty material handling applications.

The installation process for A55 crane rail involves the following steps:

1. Prepare the foundation – excavate and level the foundation surface, install sleepers or base plates, and make sure the rail alignment is correct.

2. Assemble the rail joints – join the rail sections using fishplates or splice bars, and tighten the bolts.

3. Lay the rail – place the rail sections on the sleepers or base plates, and adjust the rail position with shims if necessary.

4. Fix the rail – fasten the rail to the sleepers or base plates with rail clips or rail bolts, ensuring that the rail is straight and level.

5. Inspect the rail – check the rail alignment, fastening, and joint connection to ensure they meet the requirements.

It is important to follow the manufacturer’s instructions and safety guidelines during the installation process. It is also recommended to hire experienced rail contractors to carry out the installation to ensure high quality and safety standards are met.

We can supply the international standard flat bottom rails as below, if you need any one, please feel free to ask us: