Marine steel plate is a type of steel plate that is specifically designed for use in seawater environments. It is made with high-strength, low-alloy steels that can resist corrosion, abrasion, and fatigues from the harsh conditions of the ocean. The manufacturing process involves using special production methods such as controlled rolling, and different grades and thicknesses of steel plates are produced depending on the expected use and function. Marine steel plates are commonly used in shipbuilding, offshore drilling rigs, and other marine structures due to their high strength, durability, and corrosion resistance properties.

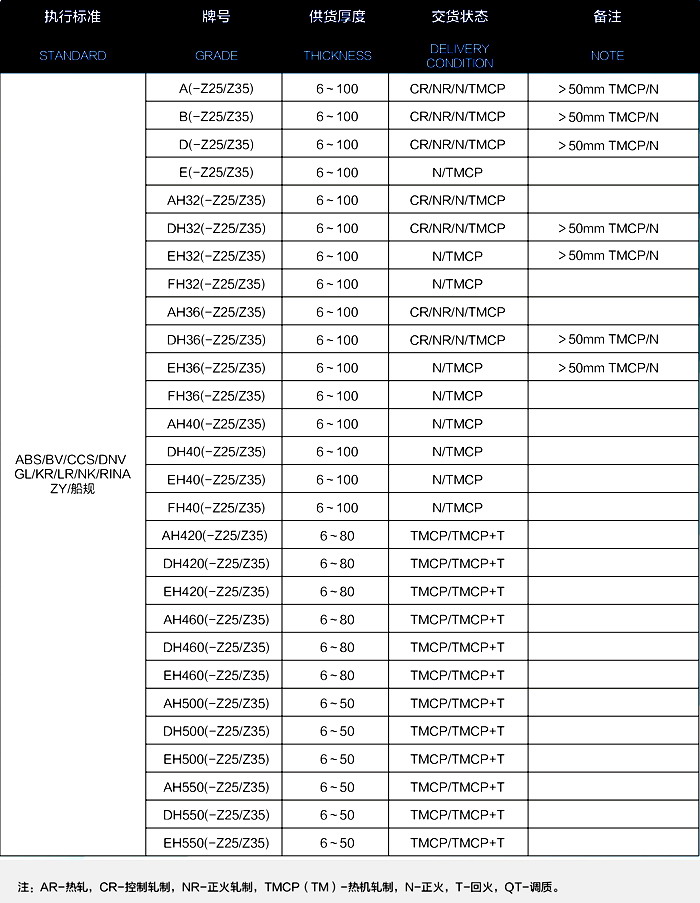

Marine steel plates can have different grades, depending on the intended use and the specific properties required for the steel plate. Some of the commonly used grades of marine steel plates include ABS Grade A, B, D, E, AH32, DH32, EH32, FH32, AH36, DH36, EH36, and FH36. These grades are classified by the American Bureau of Shipping (ABS), which is a leading classification society for marine vessels and structures. Other classification societies such as DNV, BV, LR, and RINA also have their own grading systems for marine steel plates. Each grade has specific mechanical, chemical and physical properties that make it suitable for different applications in the marine industry.

The selection of the appropriate grade of marine steel plate for shipbuilding depends on various factors, such as the type of vessel, its intended use, the operating conditions, and the regulatory requirements. Here are some basic guidelines for selecting different grades of marine steel plates:

1. Consider the type of vessel: Different types of vessels have different requirements for the strength, toughness, and corrosion resistance of the steel plates. For example, offshore support vessels require high toughness and fatigue resistance, while LNG carriers require high strength and low-temperature toughness.

2. Consider the operating conditions: The operating conditions of a vessel, such as the temperature, pressure, and exposure to saltwater and other corrosive environments, can affect the performance and durability of the steel plates. Therefore, it is important to choose a grade that can withstand the specific operating conditions of the vessel.

3. Consider the regulatory requirements: The marine industry is subject to various international and national regulations that govern the design, construction, and operation of vessels. These regulations often specify the minimum requirements for the mechanical properties, chemical composition, and testing procedures of the steel plates used in shipbuilding. Therefore, it is important to choose a grade that meets the regulatory requirements of the intended application.

In summary, selecting the appropriate grade of marine steel plate for shipbuilding requires a detailed understanding of the specific requirements and operating conditions of the vessel, as well as the relevant regulatory standards. Consulting with a qualified marine engineer or naval architect can help ensure that the chosen grade meets these requirements and contributes to the safe and efficient operation of the vessel.

BV-A and BV-D are classification society notations used by Bureau Veritas (BV) to identify the class requirements and standards that a vessel has been built and maintained to. These notations do not have a specific “grade” as they are used to classify different types of vessels for different purposes such as offshore support vessels, tankers, container ships, bulk carriers, and so on. The requirements for each BV notation vary depending on the type of vessel and its intended use.

BV/A is the plate certified by the French Bureau of Shipping. The general strength shipbuilding plate specified by China Classification Society can be divided into four quality grades: A, B, D and E; High strength structural steel is divided into four quality levels: A, D, E, and F, with three strength levels (32, 36, and 40).

There are four toughness levels of ordinary strength steel for ship plating: A, B, D, and E. The strength of each level is 235MPa, but the low-temperature toughness is different. They have the same impact resistance at 20 ° C, 0 ° C, -20 ° C, and -40 ° C, respectively;

BV/A ship plate heat treatment is hot-rolled

Performance requirements for BV/A ship plate steel plate thickness direction: Z15, Z25, Z35.

BV/A ship plate flaw detection requirements: first, second, and third detections.

We can supply all kind of marine plate with CCS or BV certification: