AREMA standard 132RE rail

$850.00 $780.00

- Standard: AREMA, ASTM

- Grade: SS, HH

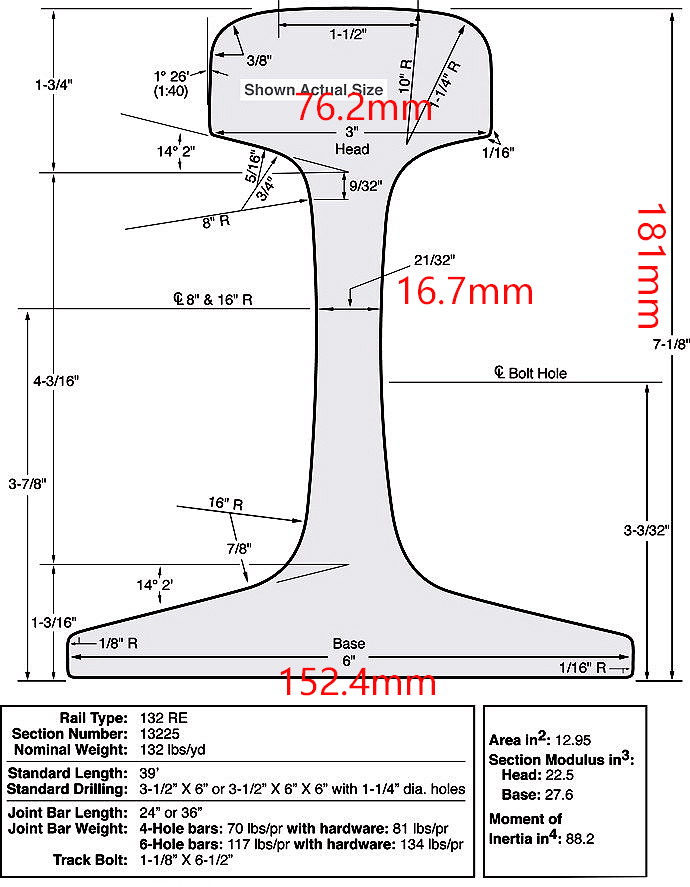

- Rail Heigth: 181mm

- Bottom Width: 152.4mm

- Web Thickness: 16.7mm

- Head Width: 76.2mm

- Length: 12-30m

- Model Number: 132RE

- Type: Heavy Rail

- Application: Railway Rail

- Weight: 65.5kg/m

- Name: 132RE America standard steel rail

- Certificate: 3.1 MTC/3.2 by Lloyd’s regiester inspection

- Market: South America

- Usage: Heavy railway line

- Description

- Exportable international standard flat bottom rail

- Producing and Inspection standard

- Inquiry

AREMA standard 132RE rail is widely used in Americas, we can produce it by order, the MOQ should be 500 tons. Material has SS and HH. Length 12m to 25m.

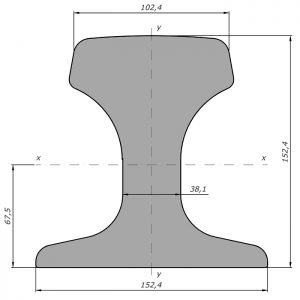

Drawing of AREMA standard 132RE rail

AREMA standard 132RE rail is a type of steel rail that conforms to the specifications set forth by the American Railway Engineering and Maintenance-of-Way Association (AREMA). This standard defines the specific requirements for the design, manufacturing, and usage of 132-pound per yard rail, which is commonly used in heavy-haul freight railroads and high-speed passenger rail lines.

Key features and characteristics of AREMA standard 132RE rail include:

1. Profile: The 132RE rail has a specific profile that conforms to the AREMA standard. This includes the dimensions of the rail head, web, base, and overall cross-sectional geometry. The precise profile is designed to ensure compatibility with other track components and to meet the load-bearing requirements of heavy-haul and high-speed rail operations.

2. Weight: The “132RE” designation indicates that the rail weighs 132 pounds per yard. This heavier weight is suitable for applications where trains carry substantial loads or operate at high speeds, requiring a rail with greater strength and durability.

3. Material: 132RE rails are typically made from high-strength steel with specific chemical compositions and mechanical properties. These materials are chosen to provide excellent resistance to wear, fatigue, and other forms of degradation, ensuring a long service life under demanding operating conditions.

4. Installation: The installation of 132RE rails involves securing them to the railway ties or sleepers using appropriate fastening systems, such as clips, bolts, or spikes. Proper installation techniques are crucial to maintaining the integrity and stability of the track structure.

5. Applications: AREMA standard 132RE rail is commonly used in heavy-haul freight railroads, as well as high-speed passenger rail lines. Its robust design and weight make it suitable for supporting heavy axle loads and high-speed train operations, contributing to safe and efficient rail transportation.

6. Maintenance: Regular inspection and maintenance of 132RE rails are essential to ensure safe and reliable rail operations. This includes monitoring for wear, defects, and other issues, as well as performing preventive maintenance activities to extend the service life of the rail.

In addition to the specific technical requirements, AREMA standard 132RE rail also encompasses guidelines for quality control, testing, and inspection procedures to ensure that the manufactured rails meet the necessary standards for performance and safety.

Overall, AREMA standard 132RE rail plays a critical role in supporting heavy-haul freight and high-speed passenger rail operations. Its design and material properties are tailored to meet the rigorous demands of these applications, providing a foundation for safe, efficient, and reliable rail transportation. As with any railway component, adherence to industry standards and best practices for installation, maintenance, and inspection is essential to maximize the performance and longevity of 132RE rail in railway infrastructure.

Standard EN 13674 - 1:2003 consists of two main parts:

− qualification test and acceptance tests

Qualification tests are some other tests that were previously carried out, as for example, fracture toughness. Acceptance tests characterize the properties of the prescribed tests, which ensure production of high quality rails, and testing requirements of railway administration.

Quality of rails is based on measured values of hardness, by which they introduced new labels for steel rails.

Qualifying tests

Qualification testing must be conducted at least one in five years and the major

changes in technology, production rails. Additional testing residual stresses are carried

out on all types of steel rails every two year maximum, provided that the longitudinal

strain rate in the rails can amount to up to 250 MPa.

The prescribed qualifying examination is the following:

− fracture toughness

− fatigue crack growth rate

− fatigue testing

− residual stress in rail foot

− variation of centre line

− tensile strength and elongation

− segregation

− other qualification requirements

Acceptance tests

Within acceptance testing is carried out a series of laboratory tests such as:

− chemical composition (the maximum content of the following elements: H, O, Al, V, N and oligo elements)

− microstructure (increasing x 500)

− degree of decarburizing charred layer (allowed up to 0.25 mm)

− purity of steel (especially the presence of oxide)

− macrostructure (Baumann test)

− hardness

− tensile strength

Other acceptance testing rails are:

− dimension tolerances

− criteria (control template)

− inspection requirements / tolerances for to internal quality and surface quality

Internal state is examined ultrasound in a continuous process control, and includes at least 70% of the head and at least 60% web.

- Standard of UIC 860 V: 1996 - prescribed four types pearlite steel rails in the range of tensile strength from 700 to 1300 MPa.

- Standard EN 13674 - 2003, provides seven types pearlite steel hardness in the range 200 to 390 HBV, types steel in accordance with EN 13674, based on the values of hardness (R 200, R 220, R 260, R 260 Mn, 320 Cr, 350 HT, 350 LHT).