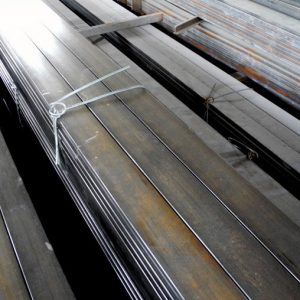

Cathode collector bar

$720.00 $600.00

SAE 1006 cathode bar should be very low carbon steel, because low carbon steel has good electroconductibility. Normally the content of carbon should less than 0.06%, the material named SAE 1006

- Description

- Quick Details

- Packaging & Delivery

- Inquiry

SAE 1006 cathode bar should be very low carbon steel, because low carbon steel has good electroconductibility. Normally the content of carbon should less than 0.06%, the material named SAE 1006, the chemical components as below:

Carbon ≤0.06%,

Silicon ≤0.07%,

Manganese ≤0.45%,

Phosphorus ≤03%,

Sulphur ≤0.04%,

Nitrogen ≤0.012%.

1 Order contents

Contracts or orders placed under this standard should include the following:

standard encdoing;

product name;

Brand number

specification;

weight;

Special technical requirements (such as guide processing, etc.)

The following definitions apply to this standard.

2 brand representation

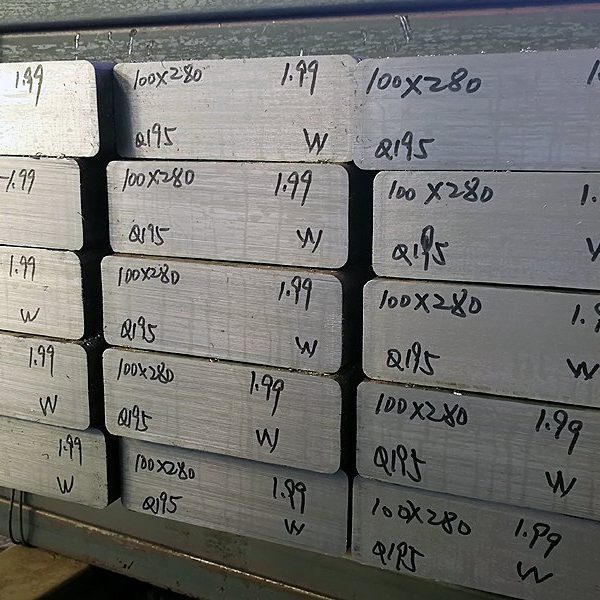

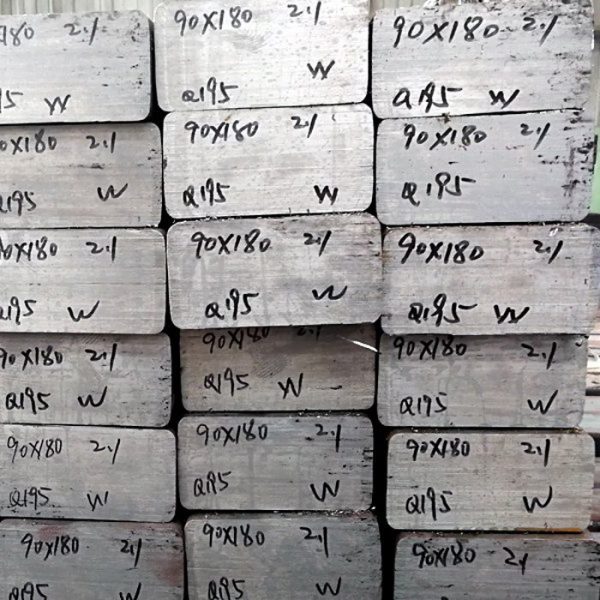

Flat steel grades are indicated by steel grades and cross-section dimensions, such as Q215-120×198. Q195 – carbon structural steel grade, 120 × 198 – the sectional size of the cathode flat steel.

3 Size, shape, weight and allowable deviation

3.1 The flat steel thickness and its allowable deviation shall comply with the requirements of Table 1.

Table 1 Thickness tolerance mm

|

Thickness |

Tolerance |

|

≥50~80 |

+2.0 -2.5 |

|

>80~120 |

+2.0 -2.0 |

|

>120~150 |

+2.5 -2.5 |

3.2 The width of the flat steel and its allowable deviation shall comply with the provisions of Table 2.

Table 2 width tolerance mm

|

Width |

Tolerance |

|

≥50~100 |

+0.0 -2.0 |

|

>100~200 |

+0.0 -2.5 |

|

>200~300 |

+0.0 -3.0 |

3.3 Flat steel length and its allowable deviation

The cathode materials is delivered according to a fixed length, the length of the fixed length shall be specified in the contract, and its allowable length deviation is 0 to +15 mm.

3.4 The bending of the length of the cathode flat bar shall comply with the requirements of Table 3.

Table 3 Curvature mm

|

Length direction |

Degree of roughness |

Distortion |

|

Thickness |

≤2mm/m |

≤1.5mm/m |

|

Width |

≤2mm/m |

≤1.5mm/m |

3.5 The four corners along the length of flat steel, the arc radius 5mm ~ 15mm.

3.6 After consultation between the supplier and the buyer, special specifications and requirements are ordered according to the agreement between the supplier and the buyer.

3.7 Weight

Cathode flat steel is delivered according to actual weight. After negotiations between supply and demand sides, they can also be delivered according to theoretical weight. Flat steel measurements are calculated according to nominal dimensions and the specific gravity is calculated at 7.85t/m3.

4 Technical Requirements

4.1 Chemical composition

4.1.1 The chemical composition of the flat steel (smelting analysis) shall comply with the provisions of Table 6.

4.1.2 After negotiations between the supplier and the buyer, other brands than GB/T 700 may also be used, and they must be specified in the contract.

The allowable deviation of the finished chemical composition of the flat steel shall comply with the provisions of GB/T 222.

4.2 Mechanical properties

The mechanical properties do not serve as delivery conditions for the cathode flat steel.

4.3 Method of manufacture

4.3.1 Smelting

Flat steel raw material is smelted by Oxygen converter of 40T or more

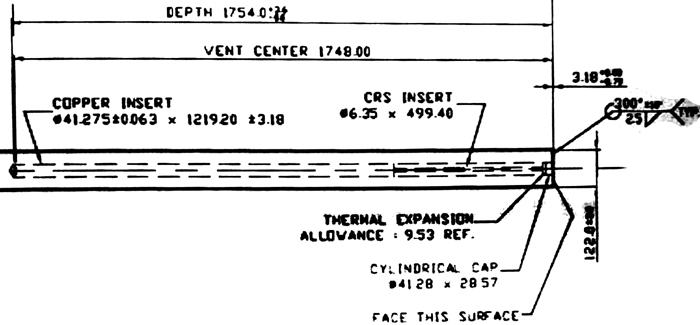

4.3.2 Roll Forming

It is rolled into rectangular strip or thick steel plate by hot rolling and then processed into rectangular flat steel according to the required size by sawing or flame cutting.

4.4 Surface quality

The surface of the flat steel must not have visible cracks, folds, scabs, inclusions, and pressed iron oxide skin. If the above defects must be removed along the length direction, the clearance depth shall be calculated from the actual size of the flat steel and shall not exceed half of the tolerance.

4.5 Internal quality

Flat steel cross-section after acid immersion low magnification test, the organization is uniform, there must be visible to the naked eye shrinkage, bubbles, cracks and other defects.

5 Test methods

The inspection items and test methods for each batch of steel shall comply with the requirements.

6.1 Inspection and Acceptance6 Inspection Rules

The inspection and acceptance of flat steel products are carried out by the supplier’s quality and technical supervision department.

6.2 Group Batch Rules

Flat steel shall be inspected and accepted in batches. Each batch consists of the same brand and the same size as the furnace.

6.3 Sample size and sampling location

The sampling quantity and sampling location of each batch of steel shall comply with the requirements of Table 5.

6.4 Review and Decision Rules

Flat steel re-inspection and determination rules according to GB/T 17505 regulations.

7 Packaging, Signs, and Quality Certificates

7.1 Flat steel must be delivered in bales. The weight of each bale is determined by the parties to the supply and demand.

7.2 Three bundles shall be bundled for each full length of bundle and shall be firm, fastened, and flush at both ends.

7.3 The flat steel mark and quality certificate shall meet the relevant requirements of GB/T 2101.

- Grade: SAE 1006 Cathode bar

- Thickness: 50-150mm

- Width: 50mm-300mm

- Length: 1000~3000mm

- Place of Origin: China (Mainland)

- Model Number: SAE 1006/Q195

- Application: Electrolytic aluminium factory Cathode flat bar

- Technique: Hot Rolled

- Special Use: Rolled steel

- Product Name: Cathode flat for Aluminum melting

- Type: Any required size

- Shape: Square Bar

- Material: SAE 1006/Q195

- Technology: Hot rolled

- Delivery Condition: Slotted

- Surface: Plain

- Surface treatment: Curved angle

- Certificate: Quality certificate

- Name: SAE 1006/Q195 - Cathode flat for Aluminum melting

-

- Packaging Details: In bundle can be loaded by forklift

- Delivery Time: 30 days

- Supply Ability: 5000 Ton/Tons per Day

- Port: Tianjin port

Related Products

-

Read MoreQuick View

Read MoreQuick ViewSAE1006 low carbon steel bar for Aluminum electrowinning

SAE 1006/Q195 Aluminum melting cathode electrowinning is used for electrolytic aluminium factory, the low carbon steel has good electrical conductivity. To produce cathode collector bar of electrolytic aluminum is a strict process, because the electrowinning system is heavy DC current, the electroconductivity will decide the cost of Aluminum, so it must have very good electroconductivity, to save power consumption and raise the electrolytic efficiency.

$720.00$600.00 -

Read MoreQuick View

Read MoreQuick ViewQ345 cold drawn rail flat bar

$600.00Rail flat bar is used for a lot of structure, we can produce any material and size as your request, also can produce smooth surface flat bar, the size as below:

10x30x6000mm Q235 flat bar

20x35x6000mm Q235 flat bar

30x40x6000mm Q234 flat bar

(10-30)x(30-120)x6000mm Q235/Q345 flat bar

40x40x6000mm ST52 rail flat bar

60x40x6000mm ST52 rail flat bar

70x40x6000mm ST52 rail flat bar

80x40x6000mm ST52 rail flat bar

-

Read MoreQuick View

Read MoreQuick ViewAngle bar for transmission tower making or marine shipbuilding

An angle bar, also known as an L-bar or angle iron, is a commonly used structural steel component in the construction of transmission towers and marine shipbuilding.

In the construction of transmission towers, angle bars are used as important structural members to provide stability and support. They are often used as braces, cross arms, and diagonal members to withstand the various loads and forces that the tower may experience, such as wind, ice, and the weight of transmission lines. Angle bars are chosen for their strength, versatility, and cost-effectiveness in these applications.

In marine shipbuilding, angle bars are also widely utilized. They are used for various applications such as framing, stiffening, and supporting structures. Angle bars provide structural integrity and stability to the ship’s hull and superstructure. They are used in the construction of bulkheads, frames, decks, and other critical components. Angle bars are preferred in shipbuilding due to their high strength-to-weight ratio, ease of fabrication, and cost-effectiveness.$650.00$560.00 -

Read MoreQuick View

Read MoreQuick ViewCathode collector bar for Aluminum melting plant

SAE 1006 Cathode collector bar is used for electrolytic aluminium factory, the low carbon steel has good electrical conductivity. To produce cathode collector bar of electrolytic aluminum is a strict process, because the electrowinning system is heavy DC current, the electroconductivity will decide the cost of Aluminum, so it must have very good electroconductivity, to save power consumption and raise the electrolytic efficiency.

$720.00$600.00 -

Read MoreQuick View

Read MoreQuick ViewQ195 Cathode flat steel

Q195 cathode flat steel is used for electrolytic aluminium factory, the low carbon steel has good electrical conductivity. To produce cathode collector bar of electrolytic aluminum is a strict process, because the electrowinning system is heavy DC current, the electroconductivity will decide the cost of Aluminum, so it must have very good electroconductivity, to save power consumption and raise the electrolytic efficiency.

$720.00$600.00 -

Read MoreQuick View

Read MoreQuick ViewQ345B rail flat bar

$600.00Rail flat bar is used for a lot of structure, we can produce any material and size as your request, also can produce smooth surface flat bar, the size as below:

10x30x6000mm Q235 flat bar

20x35x6000mm Q235 flat bar

30x40x6000mm Q234 flat bar

(10-30)x(30-120)x6000mm Q235/Q345 flat bar

40x40x6000mm ST52 rail flat bar

60x40x6000mm ST52 rail flat bar

70x40x6000mm ST52 rail flat bar

80x40x6000mm ST52 rail flat bar

-

Read MoreQuick View

Read MoreQuick ViewSWRH82B steel billet belong to high carbon steel

We can supply any kind of steel billets in large quantity with competitive price, especially special steel, such as: SWRH82B, SWRH62A/72A or SWRM8.

Dimension: 11m × 152mm × 152mm.

If you need it, please leave message to us.

-

Read MoreQuick View

Read MoreQuick ViewSteel collector bar for Aluminum melting plant

The innovative cathode collector bar should be very low carbon steel, it is ASTM Grade 1006 low carbon steel, because low carbon steel has good electroconductibility. Normally the content of carbon should less than 0.06%, the material named SAE 1006, the chemical components as below:

Carbon ≤0.06%, Silicon ≤0.07%, Manganese ≤0.45%, Phosphorus ≤03%, Sulphur ≤0.04%, Nitrogen ≤0.012%.$720.00$600.00 -

Read MoreQuick View

Read MoreQuick ViewSAE1006 Cathode bar

SAE 1006 Cathode bar is used for electrolytic aluminium factory, the low carbon steel has good electrical conductivity. To produce cathode collector bar of electrolytic aluminum is a strict process, because the electrowinning system is heavy DC current, the electroconductivity will decide the cost of Aluminum, so it must have very good electroconductivity, to save power consumption and raise the electrolytic efficiency.

$720.00$600.00 -

Read MoreQuick View

Read MoreQuick ViewSWRH72A steel billet for high carbon steel wire rod

We can supply any kind of steel billets in large quantity with competitive price, especially special steel, such as: SWRH82B, SWRH72A or SWRM8.

Dimension: 11m × 152mm × 152mm.

If you need it, please leave message to us.