DIN536 A150 Crane rail

$1,000.00 $980.00

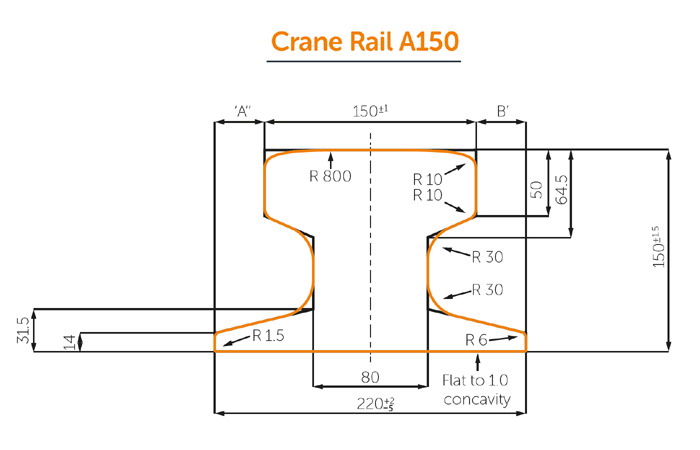

- Standard: DIN

- Grade: 900A

- Rail Heigth: 150mm

- Bottom Width: 220mm

- Web Thickness: 80mm

- Head Width: 150mm

- Length: 12m

- Model Number: A150

- Weight: 150.3 kg/m

- Product name: A150 Crane rail

- Usage: For crane runing

- Material: 900A

- Kinds: DIN536 Crane rail

- Certificate: Certificate of quality 3.1/3.2

- Market: British commonwealth of nations

- Warranty: 12 Months

- HS CODE: 73021000

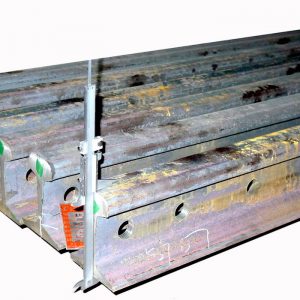

- Package: In bundle to 40 feet container

- Description

- Exportable flat bottom rail

- Inquiry

DIN536 A150 Crane rail is used for crane trolley, lifting trolley and port running crane, we also can supply the whole workable fasteners, such as weld rail clamp and rubber pad.

HS Code Description

73021000 A150 Crane rail, Material 900 A, Length 12 meters, Unit weight 150.3 kg/m

85479090 Rubber pad, 7*220*12000 mm

86080090 Double weld rail clamp, Distance 0.5/0.6 m

DIN536 A150 crane rail is a type of steel rail that is used in the construction of overhead cranes and other heavy-duty handling equipment. The rail is designed to provide a smooth and stable support surface for the wheels of the crane, allowing it to move along the length of the track while carrying heavy loads.

Here are some key features and characteristics of DIN536 A150 crane rail:

1. Profile: The DIN536 A150 crane rail has a specific profile that conforms to the German Institute for Standardization (DIN) specifications. This includes the dimensions of the rail head, web, base, and overall cross-sectional geometry. The precise profile is designed to ensure compatibility with other track components and to meet the load-bearing requirements of heavy-duty crane operations.

2. Weight: The “A150” designation indicates that the rail weighs approximately 150 kilograms per meter (101 pounds per yard). This weight is suitable for applications where cranes carry substantial loads or operate at high speeds, requiring a rail with greater strength and durability.

3. Material: DIN536 A150 crane rails are typically made from high-strength steel with specific chemical compositions and mechanical properties. These materials are chosen to provide excellent resistance to wear, fatigue, and other forms of degradation, ensuring a long service life under demanding operating conditions.

4. Installation: The installation of DIN536 A150 crane rails involves securing them to the support structure using appropriate fastening systems, such as bolts or clips. Proper installation techniques are crucial to maintaining the integrity and stability of the rail track.

5. Applications: DIN536 A150 crane rail is commonly used in overhead crane systems, gantry cranes, and other heavy-duty handling equipment. Its robust design and weight make it suitable for supporting heavy loads and high-speed crane operations, contributing to safe and efficient material handling.

6. Maintenance: Regular inspection and maintenance of DIN536 A150 crane rails are essential to ensure safe and reliable crane operations. This includes monitoring for wear, defects, and other issues, as well as performing preventive maintenance activities to extend the service life of the rail.

Overall, DIN536 A150 crane rail plays a critical role in supporting heavy-duty material handling operations. Its design and material properties are tailored to meet the rigorous demands of these applications, providing a foundation for safe, efficient, and reliable material handling. As with any industrial equipment, adherence to industry standards and best practices for installation, maintenance, and inspection is essential to maximize the performance and longevity of DIN536 A150 crane rail in material handling systems.