EN13674-4 45E1 steel rail

$850.00 $800.00

- Standard: BS

- Grade: 900A/1100

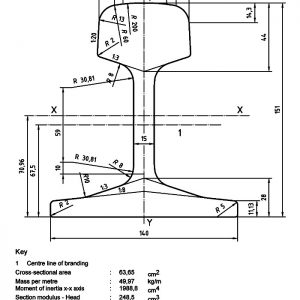

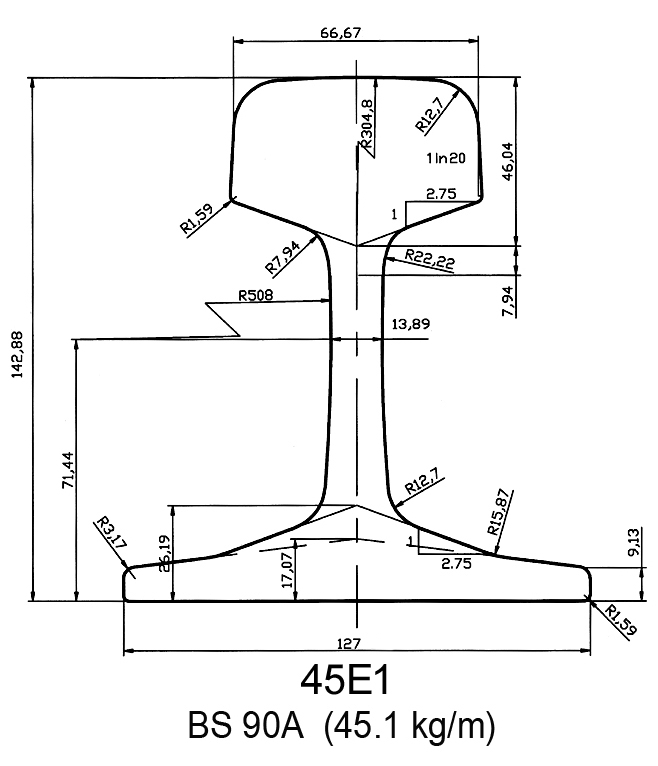

- Rail Heigth: 142.88mm

- Bottom Width: 127mm

- Web Thickness: 13.89mm

- Head Width: 66.67mm

- Length: 12-36m

- Model Number: BS90A

- Type: 45E1 rail

- Application: Railway Rail

- Weight: 45.1 kg/m

- New type: EN13674-4 45E1 900A steel rail

- BS type: BS11-1985 Standard BS90A steel rail

- Material: UIC860V 900A/1100

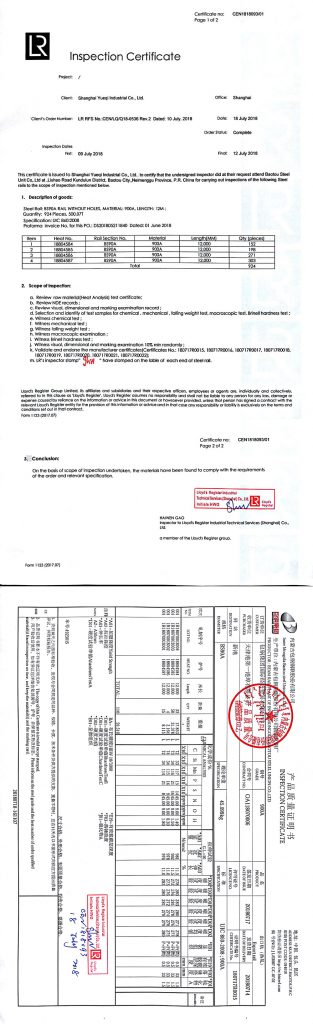

- Certificate: Certificate 3.1 & 3.2 by Lloyd’s regiester

- Other name: 45E1 steel rail

- Producing standard: UIC860V

- Steel grade: R260/R320/350HT

- Steel number of EN10027-2: 1.0521

- Steel number of EN10027-2: 1.0524

Delivery term: 30 days

Delivery port: Tianjin port

Payment term: T/T, L/C

- Description

- Exportable international standard flat bottom rail

- Strict inspection process by Lloyd's

- Inquiry

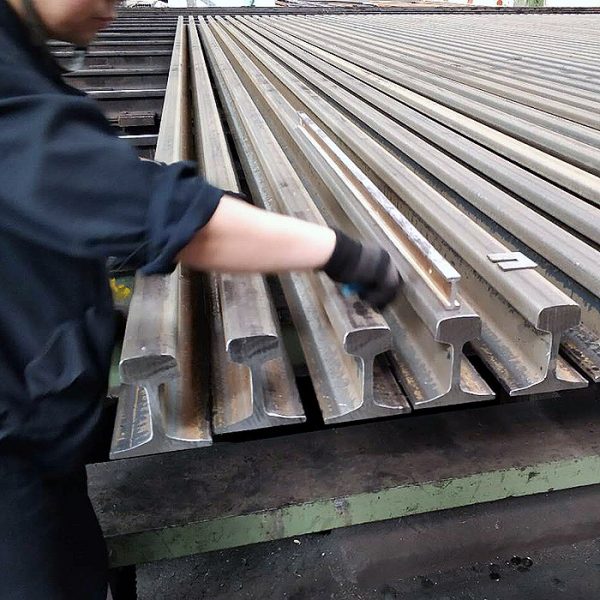

EN13674-4 45E1 steel rail is used for factory railroad line or subway railway line, it is wildely used in British commonwealth of nations, we can produce it by order, the MOQ should be 500 tons. Material can be 900A, length can be 12 to 25 meters.

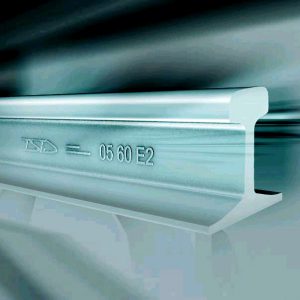

Drawing of EN13674-4 45E1 steel rail

| Specification: 45E1 steel rail | |||||||

| Standard: BS11-1985 | |||||||

| Material: 700/900A | |||||||

| Length: 8-12m |

The EN13674-4 45E1 steel rail is a standard rail profile that is commonly used in railway infrastructure projects across Europe and other regions that follow the European Norm (EN) system of standards. It is designed to meet the requirements of heavy-duty railway operations, including freight and passenger trains.

The EN13674-4 45E1 steel rail has a weight of 45 kilograms per meter and features a standard profile with a height of 176 millimeters, a base width of 132 millimeters, and a head width of 76 millimeters. The rail also has a web thickness of 20 millimeters and a flange thickness of 25 millimeters.

The 45E1 rail is made from high-quality carbon-manganese steel that undergoes rigorous manufacturing processes to ensure optimal mechanical properties and longevity. The rail is heat-treated to increase its hardness and wear resistance, making it suitable for use in harsh operating environments.

The EN13674-4 45E1 steel rail is designed with safety in mind, featuring a continuous welded structure that minimizes the risk of rail breaks or derailments. It is also equipped with special fittings such as fishplates, bolts, and clips that ensure a secure connection between the rails and prevent movement or displacement.

To ensure the quality and reliability of the EN13674-4 45E1 steel rail, it undergoes rigorous testing and certification processes before being approved for use. These tests include tensile strength tests, impact tests, and fatigue tests, among others, to verify the rail’s mechanical properties and performance under different operating conditions.

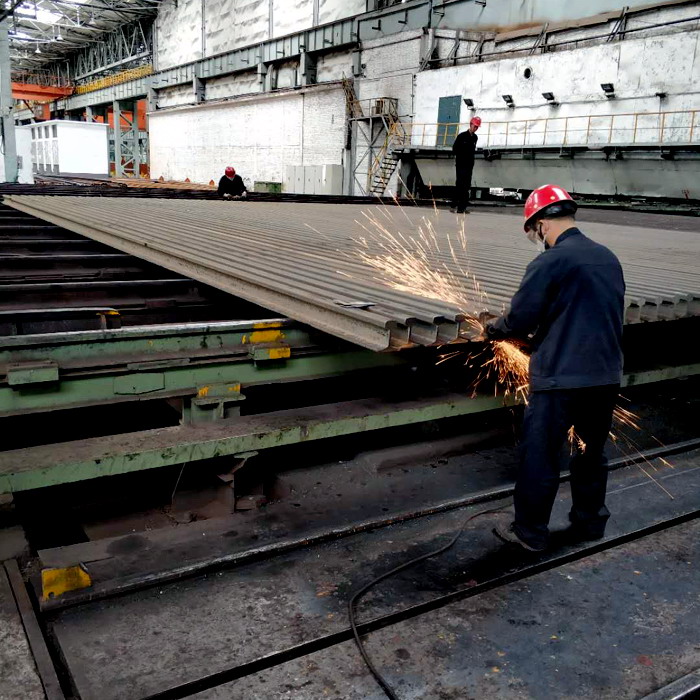

The installation of the EN13674-4 45E1 steel rail requires specialized equipment and expertise, as well as careful planning and design. The rail must be installed on a solid foundation that can support the weight of the trains and other equipment, and it must be properly aligned and maintained to ensure optimal performance and safety.

Overall, the EN13674-4 45E1 steel rail is a reliable and durable rail product that is widely used in railway infrastructure projects around the world. Its high strength, durability, and safety features make it an ideal choice for a wide range of applications, including mainline railways, industrial tracks, and mining operations. As a supplier of railway track products, we offer a range of high-quality EN13674-4 45E1 steel rails and related components to meet the needs of our customers in the railway and industrial sectors. If you require more information or would like to request a quote, please do not hesitate to contact us.

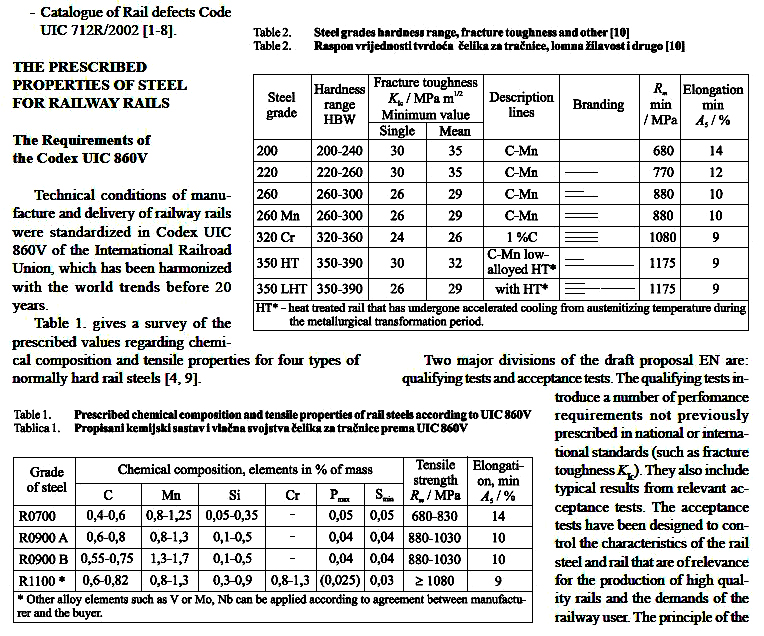

– Standard of UIC 860 V: 1996 – prescribed four types pearlite steel rails in the range of tensile strength from 700 to 1300 MPa.

– Standard EN 13674 – 2003, provides seven types pearlite steel hardness in the range 200 to 390 HBV, types steel in accordance with EN 13674, based on the values of hardness (R 200, R 220, R 260, R 260 Mn, 320 Cr, 350 HT, 350 LHT).