ISCOR 57 South African steel rail

$900.00 $850.00

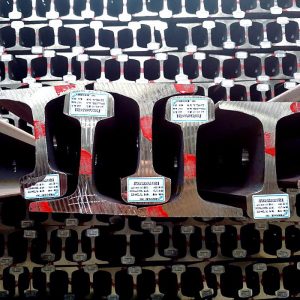

ISCOR 57 South African standard steel rail

Length: 12 to 30 meters;

Unit weight: 57.40 kg/m;

MOQ: 2500 tons

Delivery term 45 days

Delivery port: Tianjin port

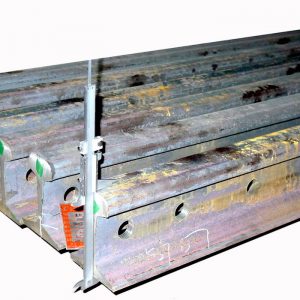

Packing: In bundle by bulk cargo

- Description

- Exportable international standard flat bottom rail

- Why to choose us?

- Inquiry

ISCOR 57 South African steel rail is used for South Aferica area railway line, we can produce it by order, the MOQ should more than 2500 tons, length can be 12-25 meters, hardness R260/R320Cr/R350HT, delivery term will be more than 30 days.

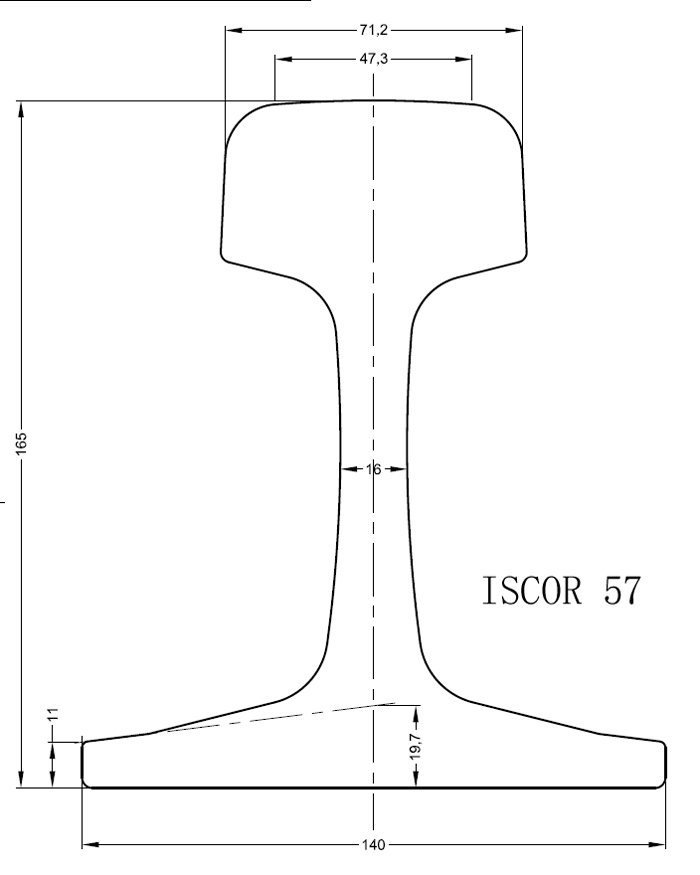

Length: 12 to 25 meters;

Unit weight: 57.40 kg/m;

Production standard: UIC860;

Delivery inspection standard: EN13674 for qualifying tests and acceptance tests;

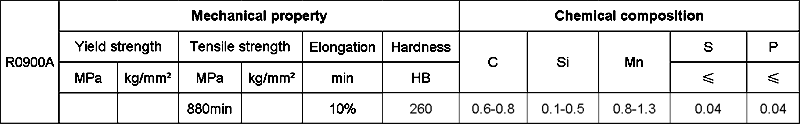

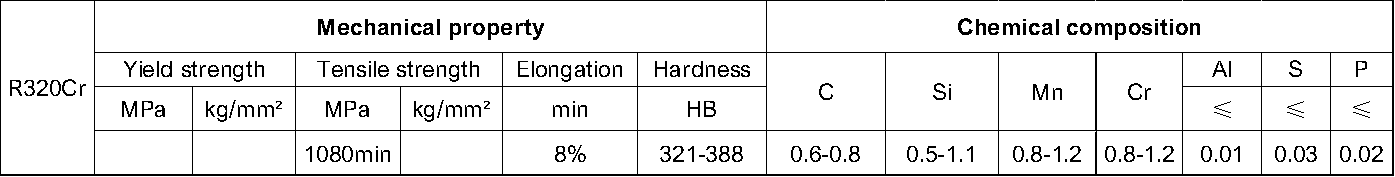

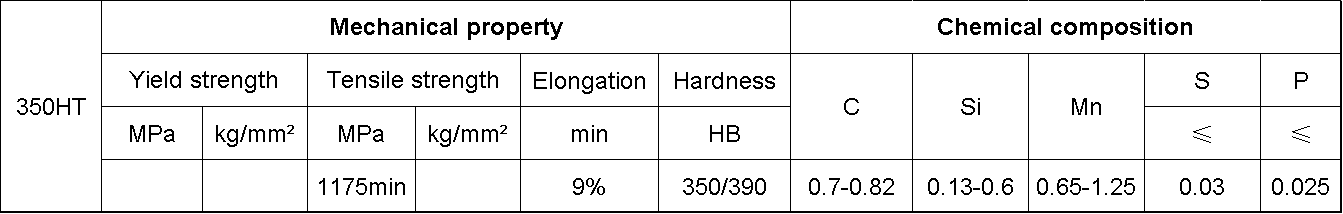

Material: R900A/R1100;

Hardness: R260, R320, R350HT.

ISCOR 57 South African steel rail is a type of railway rail that conforms to the specifications set by the South African Bureau of Standards (SABS) and was previously manufactured by ISCOR, a South African state-owned steel company.

The “57” in the name refers to the weight of the rail in kilograms per meter. Thus, the ISCOR 57 rail weighs 57 kilograms per meter. This rail is commonly used in mainline railway networks in South Africa and other countries where it has been exported.

ISCOR 57 South African steel rail typically has a height (also known as the rail head) of around 132-140 millimeters, a base width of approximately 140-150 millimeters, and a web thickness of around 8-10 millimeters. It is made from high-quality carbon steel and may be heat-treated or quenched and tempered to provide the necessary strength and durability for railway operations.

ISCOR 57 South African steel rail is designed to withstand heavy axle loads and high traffic volumes typical of mainline railway networks. It is also suitable for use in curved tracks and can be welded or joined using fishplates to create continuous rail lines.

While ISCOR is no longer in operation, ISCOR 57 South African steel rail remains a widely used standard in South Africa and other countries where it has been adopted. Proper installation, maintenance, and inspection of the ISCOR 57 rail are essential to ensure its continued safe and efficient operation in railway networks.

I. Rail for Railway

1. Chinese Standard: TB/T2344-2012, TB/T3276-2011

43 kg/m rail, 50 kg/m rail, 60 kg/m rail, 75kg/m rail

Material: U71Mn, U75V, U76CrRE, U20Mn

2. GOST Standard: GOST-R51685

P50 rail/R50 rail, P65 rail/R65 rail, P75 rail/R75 rail

Material: K76, M76T

3. DIN Standard: DIN5901-1955

S10, S14, S18, S20, S30, S33, S41, S49 rail, UIC54 rail, UIC60 rail

Material: 900A, 350HT

4. Japanese & Korean Standard: JIS E1101

JIS15kg, JIS22kg, JIS30kg, JIS37A, JIS50N rail, JIS60 rail, CR73, CR100 rail

Material: 235HBW, 340HH, 370HH

5. Australian Standard: AS1085, BHP RT STD

AS50 rail, AS60 rail, AS68 rail, AS73, AS86, AS89 rail

Material: R260, R320, R350HT

6. AREMA Standard: ASTM A1

ASCE25, ASCE30, ASCE40, ASCE60, ASCE75, ASCE85, 90 RA rail, 100 RE rail, 115 RE rail, 132 RE rail, 136 RE rail, 175LBS rail

Material: SS, HH, 700/900A/1100

7. AREMA Standard: ASTM

TR45 rail, TR50 rail, TR57 rail, TR68 rail

Material: R260, R320, 350HT

8. BS Standard: BS11-1985

BS50 O rail, BS60A rail, BS60R rail, BS70A rail, BS75A rail, BS75R rail, BS80A rail, BS80R rail, BS90A rail, BS100A rail, BS113A

rail.

Material: 700, 900A, 1100

9. EN Standard: EN 13674-1

49E1/49E2 rail, 50E1/50E2/50E4/50E5/50E6 rail, 54E1/54E2/54E3 rail, 55E1, 60E1 rail, 60E2 rail

Material: R260, R320Cr, R350HT

10. ISCOR South African standard rail

ISCOR 15, ISCOR 22, ISCOR 30, ISCOR 48 rail, ISCOR 57 rail

Material: 700, 900A

11. ISCR Indian standard: IS 3443

ISCR 70, ISCR 80, ISCR 100, ISCR 120 rail

Material: U71Mn

II. Switch Rail

Standard: TB/T3109-2013

50AT1 rail, 60AT1 rail, 60AT2 rail, 60TY1 rail

Material: U71Mn, U75V, U76CrRE

III. Crane Rail

1. Standard: YB/T5055-2014, QU70 rail/KP70 rail, QU80 rail/KP80 rail, QU100 rail/KP100 rail, QU120 rail/KP120 rail.

Material: U71Mn, 900A

2. ASTM A759-2000 crane rail: CR175 rail, Material: 900A/1100

3. DIN536 crane rail: A45, A55, A65, A75, A100, A120, A150 crane rail. Material: 900A

IV. Grooved Rail

Standard: EN 14811:2006

59R1/59R2 rail, 60R1/60R2 rail

Material: U75V

Why the quality of our steel rail is very good?

1. Because we control the producing process since steel melting.

(1) Rail was produced by very specialized process.

(2) Liquid iron will be desulfurization before steel marking.

(3) Slag stoppers are used in tapping operation to eliminate or minimize the carryover of slag into the steel ladle.

(4) The steel ladle will be stirred by argon in the bottom for liquid steel temperature homogenized, steel composition uniformed and removal of nonmetallic inclusions.

(5) On the top of ladle add insulating slag as precaution after tapping.

(6) Steel temperatures, chemical compositions and deoxidation practices can be controlled more precisely by second refining.

Vacuum degassing is used for removing gases such as hydrogen, oxygen and nitrogen. Improve the purity of steel through removing oxygen and removing nonmetallic inclusions by flotation.

(7) Avoid second oxidation in continuous casting through in-ladle slag carryover predication, protective casting, tundish metallurgy and mould level automatic control.

(8) Improve the surface quality and segregation through control the constant casting speed, in-mould electromagnetic stirring, dynamic control of secondary cooling and soft reduction in final stage.

(9) Rolling by Universal mill and right designing to ensure the better profile and tolerance.

(10) Two times descaling will be used to improve rail surface quality.

(11) The independent drive prebend device is used to prebend the rail reliably and remove the bending rail safely during the cooling process to reduce the residual stress.

(12) All rail shall be straightened and ultrasonically tested by a continuous process to ensure whole of rails length and specified cross sectional area are inspected fully.

3. Inspection and Test Plan shall be arranged as per the technical specification and contract before production.

4. Mill’s Certificate: Products can’t be sold and dispatched from the factory if it is not qualified.

5. Shipment: The rail will be delivered by railway or truck according to different length.

6. Loading and unloading shall use special rail clamp, to avoid the head of rail damage.

7. Loading plan shall be arranged before loading according to different vessel to ensure quality and safety of the goods.

Application cases:

- High and cold area railway from Qinghai to Tibet.

- Heavy cargo railway from Datong to Qinhuangdao.

- Shenhua special railway line for coal transport.

- North and South railway in Brazil.

- Electrified Double Tracking Project (Iroh-Padang Besar).

- Tonkolili iron ore and related infrastructure projects.

- Track Rehabilitation Phase 6 in Thailand.

- Laksham and Tongi Project in Bangladesh.

- Pakistani railway line.

- Indonesia market.

Delivery to sea port by train