Subway aluminum conductive rail

$4,000.00 $3,800.00

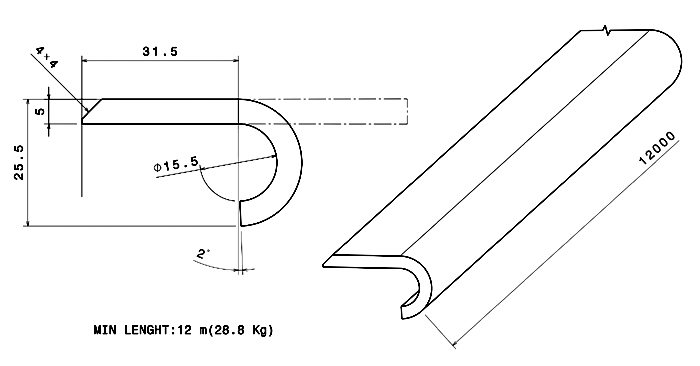

- Standard: DIN

- Grade: 6063-T6

- Rail Heigth: 100mm

- Bottom Width: 80mm

- Web Thickness: 18mm

- Head Width: 80mm

- Length: 12m

- Place of Origin: HEN

- Brand Name: YUEQI

- Model Number: 6063-T6

- Type: Third Conductive Rail

- Application: Underground railway current rail

- Weight: 17.6 kg/m

- Secondary Or Not: Non-secondary

- Bolt Hole Diameter: non

- Tolerance: ±1%

- Alloy Or Not: Is Alloy

- Delivery Time: 46-60 days

- Product name: Third steel-aluminum conductor rail

- Name: Current contact rail

- Other name: conductive rail

- Material: Al. 6063-T6, Stain. St 430

- Applicaiton: metro electric conductive rail

- Standard of Products: DIN 7168-m

- Certificate: MTC 3.1

- Warranty: 12 months

- Name of Commodity: subway third rail

- HS CODE: 73089000

- Supply Ability: 3000 Ton/Tons per Month

- Packaging Details: Bundle in container

- Port: Qingdao port

- Lead time:

-

Quantity(tons) 1 – 50 51 – 200 >200 Lead time (days) 50 60 To be negotiated

- Description

- Details of manufacturer

- Inquiry

Subway aluminum conductive rail is mainly used for urban rail transit and electrified railway transmission system. Compared with the existing low carbon steel conductor rail, it has a series of advantages, such as low resistance, light weight, corrosion resistance, little wear, etc. It can save about 60% of the energy loss and the service life will be more than 50 years.

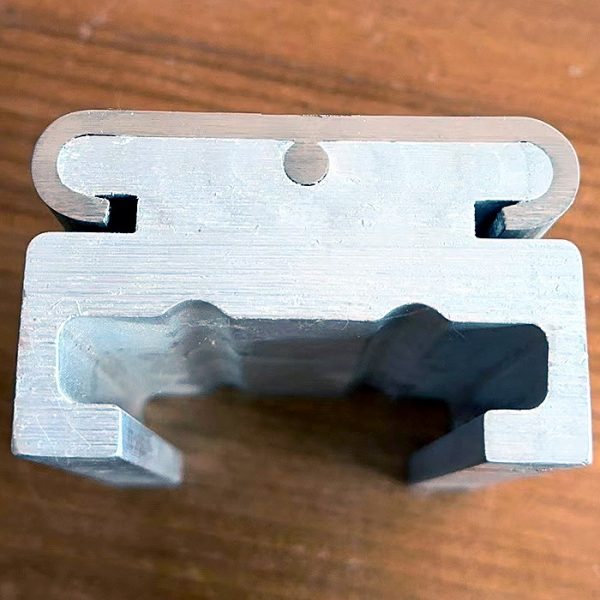

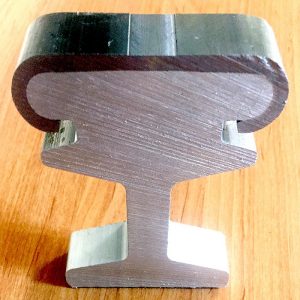

Drawing of J form cover:

Drawing of Al conductive rail:

Material of Aluminum rail:

|

Chemical composition |

||||||||||

|

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

other single |

other total |

|

|

0.2-0.6 |

0.35 |

0.1 |

0.1 |

0.45-0.9 |

0.1 |

0.1 |

0.1 |

0.05 |

0.15 |

|

Technical specification:

|

Description of contact rail |

Unit |

Data |

|

Type |

AL-ST |

|

|

Normal voltage rating |

V |

750 |

|

Maximum resistance (20°C) |

mΩ/km |

6.74 |

|

Permissible continuous current load |

A |

4500 |

|

Permissible short-circuit current |

kA |

|

|

Cross section |

mm2 |

4747.19 |

|

Weight |

kg/m |

12.817 |

|

Moment of inertia to horizontal center axle |

cm4 |

|

|

Coefficient of thermal expansion |

||

|

Manufacturer standard length |

m |

12 |

Commercial description:

| Item No. | Description |

| 1 | SS430 J form long strip, unit weight 2.4 kg/m, length 12m |

| 2 | Aluminum Third conductor rail, Material 6063-T6, Length 12m, Unit weight 12.71 kg/m |

Subway aluminum conductive rail also known as third rails or contact rails, are an essential component of the electric power supply system for many subway trains. These rails are designed to conduct electricity and provide a continuous flow of power to the trains as they move along the tracks.

Typically, aluminum is used as the primary material for these conductive rails due to its high electrical conductivity, light weight, and resistance to corrosion. The aluminum rail is usually covered with a layer of carbon-based composite material or stainless steel to improve its durability and reduce wear caused by the contact shoes of the train.

The conductive rail is usually mounted on insulators along the side or center of the track, and it is kept at a constant voltage potential. When the train moves over the rail, the contact shoes on the underside of the train make contact with the rail, completing an electrical circuit and drawing power from the rail to drive the train’s electric motors.

It is important to ensure that Subway aluminum conductive rail is properly maintained and kept free of debris or obstructions that could interfere with the flow of electricity. Additionally, safety measures such as insulation and warning signs are typically in place to protect people from coming into contact with the high-voltage rail.

Photos of manufacturer:

The steel and aluminum composite materials of the steel aluminum composite conductor rail are the solid metallurgy combination of the cleaned steel strip and aluminum profile in the mixing mold according to the conventional process parameters. This metallurgical combination is formed through the role of heat and pressure in the kneading process, and with a special conductive layer. In this process, the metal compound Al3Fe2 is formed between aluminum and iron atoms, and the metallurgical bonding between the two materials will reduce the interlayer resistance. Since there is no gap between the contact surface of steel and aluminum, the contact surface is not easy to be corroded and damaged, which can ensure the stability of low resistance for a long time. In addition, the peel test has proved that it is impossible to peel the steel strip from the aluminum body. Only special things can separate steel from aluminum. The metallurgical combination between steel and aluminum can withstand great external forces without deformation.

In addition, problems such as discoloration, scratches and scratches on the steel surface are allowed to occur during processing without affecting the practicability of the product.

The steel aluminum composite conductor rail is made of low-carbon alloy steel and aluminum alloy. Aluminum alloy is the main body of conductor rail. When selecting materials, its excellent conductive function must be considered and meet the requirements of mechanical function. First of all, the wear resistance, corrosion resistance and conductivity of steel should be considered. Chromium steel is usually selected, and its wear resistance, conductivity and thermal conductivity can basically meet the requirements of steel aluminum composite conductor rail.

Steel aluminum composite conductor rail has been proved to be a useful and reliable product in long-term application. Compared with low-carbon rail, it has the following advantages:

(1) The conductivity of aluminum alloy is 28-33ms/m, 3-4 times that of non alloy low carbon steel (8.5ms/M). The conductivity of steel aluminum composite conductor is higher than that of low carbon steel conductor. In this new equipment form, the voltage reduction reduces the traction energy consumption proportionally, which increases the power supply distance and reduces the number of substations.

(2) The specific gravity is small, and the equipment is easy to construct: the weight of the steel aluminum composite conductor is less than half of the weight of the low carbon steel conductor with the same cross section. The equipment is simple, the cost is low, and the cost is reasonable, and there is no need for lifting equipment.

(3) Good corrosion resistance and wear resistance: To ensure the excellent corrosion resistance and wear resistance of the steel strip, the steel aluminum composite conductor rail is made of chromium stainless steel with excellent intergranular corrosion resistance. The conductor rail has excellent corrosion resistance when the equipment is operated and tested in the laboratory under marine climate conditions. At the same time, the stainless steel contact surface is smooth and wear-resistant, which can extend the service life of the conductor rail and the collector.

(4) Good resistance: The kneaded composite of aluminum and stainless steel can form a variety of profiles.

(5) Good economic benefits: under the same transportation volume, the cost of steel aluminum composite conductor rail is lower than that of low carbon rail. This is due to: 1) the voltage decreases and the substation demand decreases; 2) The steel aluminum composite conductor rail is light in weight, reducing the equipment cost; 3) The annual digestion cost is low.