AS 1085 is the Australian Standard for Railway Track Materials – Rails, which specifies the requirements for steel rails used for railway tracks, including alloy composition, physical properties, and dimensions. It also includes requirements for quality control, testing, and certification.

BHP RT STD, on the other hand, is a standard set by mining and metals company BHP (formerly known as Broken Hill Proprietary) for rails used in its own rail network, but it is also widely used in other Australian railways. It sets out similar requirements to AS 1085 in terms of material properties and dimensions, but with some differences in the manufacturing process and finishing of the rails.

The railway rail standard AS1085 includes flat-bottomed rails (Type A) and grooved rails, also known as vignole rails (Type B). Flat-bottomed rails are typically used in slower speed and lighter trafficked areas, while grooved rails are used in higher speed and heavier trafficked areas.

Vignole rail, also known as flat-bottom rail or flanged T rail, is a type of railway track rail design that was invented by the French engineer Charles Vignoles in the mid-19th century. This design consists of a flat base with an upright flange on either side to guide the wheels of the train.

The Vignole rail design is commonly used in modern railways around the world due to its ease of manufacturing and maintenance. The flat bottom ensures that the rail can be easily attached to sleepers or ties with fasteners, while the upright flanges keep the train wheels aligned.

The Vignole rail design has become a standard in the railway industry, providing a reliable and efficient solution for constructing railway tracks.

The railway rail standard AS1085 specifies a range of requirements for railway rails used in Australia, including the following:

1. Material requirements, such as chemical composition and mechanical properties

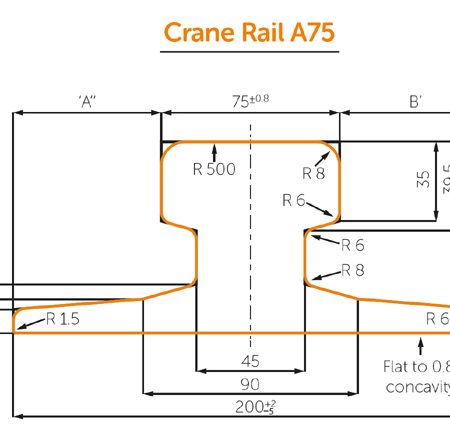

2. Physical dimensions, such as rail length, weight, and cross-sectional profile

3. Tolerances and deviations from specified dimensions

4. Surface defects and imperfections, such as cracks, laps, and splits

5. Markings and identification of rails

6. Testing and inspection procedures

7. Acceptance criteria for rails based on test results.

These specification requirements are intended to ensure that railway rails used in Australia meet the necessary safety and performance standards for railway operations.

The railway rail standard AS1085 is used in Australia for the design, manufacture, and maintenance of railway tracks. It covers a wide range of applications including heavy haul rail, urban transit systems, industrial rail facilities, and other railway infrastructure. AS1085 specifies requirements for rails made from different materials including steel, iron, and other alloys used in rail construction. It also defines the physical dimensions, tolerances, and testing procedures necessary to ensure that the railway rails meet the necessary safety and performance standards for the specific application. Therefore, AS1085 is an important standard for the railway industry in Australia.

Welcome to ask us the international standard flat bottom rails as below: