Bar ya mtoza chuma kwa mmea wa kuyeyuka wa Aluminium

$720.00 $600.00

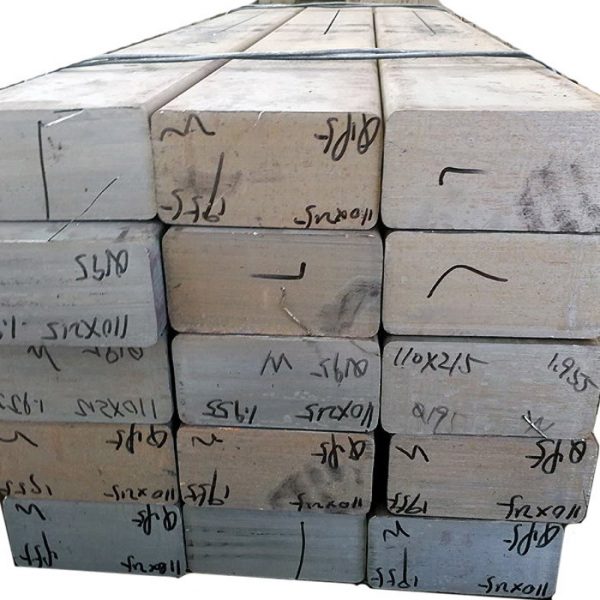

Bar ya mtoza wa cathode ya ubunifu inapaswa kuwa chuma cha chini sana cha kaboni, ni ya ASTM Grade 1006 Chuma cha chini cha kaboni, kwa sababu chuma cha chini cha kaboni kina electroconductibility nzuri. Kwa kawaida maudhui ya kaboni yanapaswa chini ya 0.06%, nyenzo inayoitwa SAE 1006, Kemikali kama ilivyo hapa chini:

Carbon ≤0.06%, Silicon ≤0.07%, Manganese ≤0.45%, Phosphorus ≤03%, Sulphur ≤0.04%, Nitrojeni ≤0.012%.

- Maelezo

- Maelezo ya Haraka

- Ufungaji na Uwasilishaji

- Uchunguzi

SAE 1006 Cathode plate for Aluminum melting, chuma cha chini cha kaboni kina conductivity nzuri ya umeme. Our product is produced in big steel factory, the quality is very good, we can supply any size products as your requirement, please contact us to talk about the details.

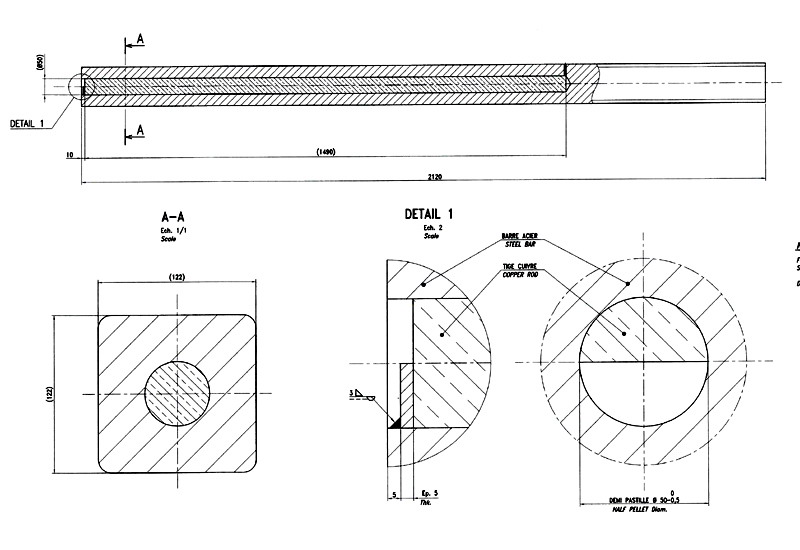

Baa za mtoza chuma zina sehemu ya mraba ya msalaba na kuingiza shaba pande zote. The quality of steel and copper insert, their dimensions and its fitting in the finished collector bar should be as below and in accordance with the drawing:

- Physical:

- Steel collector bar tolerance:

Urefu (mm) 0 / +10

Upana (mm) -2~+2

Urefu (mm) -2~+2

- Steel collector bar geometrical tolerances

- Angle defect at cut end less than 5 mm

- Flatness at cut ends less than 2 mm

- Angle defect of cross-section less than 3 mm

- Deflection on the whole bar less than 3 mm

(Laterally and Vertically)

- Local deflection less than 3 mm per meter

(Laterally and Vertically)

- Flatness less than 3 mm

(Transversally and vertically)

- Twist less than 3 mm per meter

- Round off 4-15 mm

- Steel collector bar surface condition

- Lateral surfaces: Free or metal pickup and cracks deeper than 3 mm

- Surface roughness not projecting by more than 1 mm

- Cut by saw (Cutting with shears or oxyacetylene torch are prohibited unless followed by grinding). Cuts must not present manufacturing defects (Necessitating a supplementary grinding).

- No painting on the bar ends.

- Physicochemical characteristics

- Composition of collector bar steel (Gravimetrical analysis)

The cathode bar application requires a ferrous metal with a relatively low electrical resistivity and a good weldability (Kwa mfano 1020 Grade or ASTM A29/A29 M-99) and following composition requirement:

Carbon: ≤0.06%

Silicon: ≤0.07%

Manganese: ≤0.45%

Phosphorus: ≤0.03%

Sulphur: ≤0.04%

Nitrojeni ≤0.012%.

The steel supplier must supply to the client its proposal with typical steel composition range expected for the following chemical elements: Al, C, Cr, Cu, Sc, Mn, Ni, S, P & N

- Cathode bar inspection

Acceptance of cathode bars takes place in the supplier’s premises and includes:

- A check of the quality control results of the supplier, and especially a check of the analysis certificates guaranteeing that the quality of the bar steel meets the requirements of the specification

- A check of bar dimensions are aspect.

As regards inspection procedures, the word “LOT” means “LOT of material to be inspected”, i.e. All the cathode bars, out of which a sample will be taken to check for compliance with the acceptance criteria.

The cathode bards in a given LOT must be manufactured according to the same process and with the same quality of steel.

NB: When there is no acceptance on site, all the supplier control results must be sent to the lient purchasing department before shipping for acceptance.

- Daraja:

-

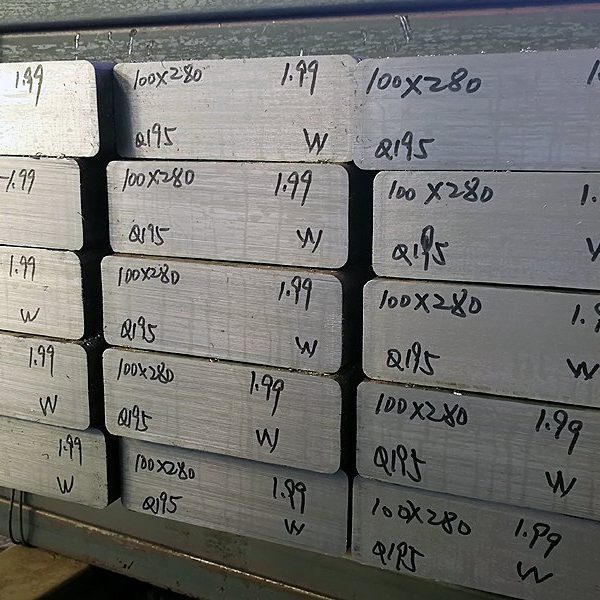

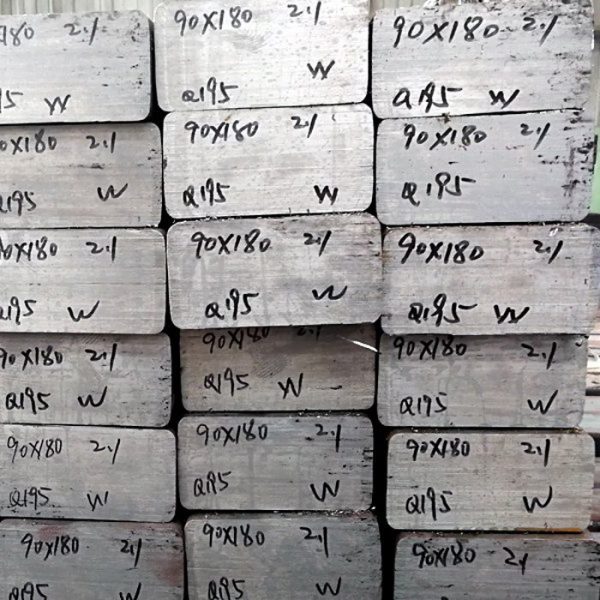

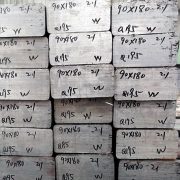

SAE 1006/Q195 Cathode plate for Aluminum melting

- Unene:

-

50-150mm

- Upana:

-

50mm-300mm

- Urefu:

-

1000~ 3000mm

- Mahali pa Asili:

-

Mongolia ya ndani, China (Bara)

- Jina la Chapa:

-

Baosteel

- Namba ya Mfano:

-

SAE 1006 / Q195

- Programu tumizi:

-

Electrolytic aluminium factory Cathode bar

- Mbinu:

-

Moto Umevingirishwa

- Matumizi Maalum:

-

Mold Steel

- Jina la Bidhaa:

-

Cathode plate for Aluminum melting

- Aina:

-

Ukubwa wowote unaohitajika

- Umbo liwe:

-

Mwambaa wa mraba

- Vifaa:

-

SAE 1006 / Q195

- Teknolojia:

-

Moto umevingirishwa

- Hali ya Uwasilishaji:

-

Iliyopangwa

- Uso:

-

Ghafi

- Matibabu ya uso:

-

Pembe ya Curved

- Cheti:

-

Cheti cha ubora

- Jina:

-

SAE 1006 / Q195 - Cathode plate for Aluminum melting

- Maelezo ya Ufungashaji

- Katika kifungu inaweza kupakiwa na forklift

- Muda wa Uwasilishaji

- 30 Siku

- Uwezo wa Ugavi:

- 5000 Ton/Tons kwa Siku

- Bandari:

- Bandari ya Tianjin

Bidhaa Zinazohusiana

-

Soma ZaidiMwoneko Chapu

Soma ZaidiMwoneko ChapuST52 bar ya gorofa ya reli

$600.00Rail flat bar hutumiwa kwa muundo mwingi, Tunaweza kutoa vifaa na ukubwa wowote kama ombi lako, pia inaweza kuzalisha bar laini ya gorofa ya uso, Ukubwa kama hapa chini:

10x30x6000mm Q235 bar ya gorofa

20x35x6000mm Q235 bar gorofa

30x40x6000mm Q234 bar ya gorofa

(10-30)x(30-120)x6000mm Q235/Q345 bar gorofa

40x40x6000mm ST52 bar ya gorofa ya reli

60x40x6000mm ST52 bar ya gorofa ya reli

70x40x6000mm ST52 bar ya gorofa ya reli

80x40x6000mm ST52 bar ya gorofa ya reli

-

Soma ZaidiMwoneko Chapu

Soma ZaidiMwoneko ChapuUjenzi wa meli sahani ya chuma laini

Kiwango cha: CCS

Daraja: 2C, 3C, 4C, 5C, 12MNC, 16MNC, 15MnTiC, 14MnVtirec

Mahali pa Asili: Liaoning, China

Jina la Chapa: Yueqi

Namba ya Mfano: A B D E AH32 AH36 DH32 DH36 EH32 EH36

Aina: Bamba la Chuma, Bamba la chini la Aloi

Mbinu: Moto Umevingirishwa

Matibabu ya Uso: Mlipuko wa mchanga na Primer

Programu tumizi: Bamba la Meli

Matumizi Maalum: Bamba la Chuma la Nguvu ya Juu

Upana: 2000mm-2500mm

Urefu: 6000mm-12000mm

Uvumilivu: ±2%

Huduma ya Usindikaji: Bending, Kulehemu, Kukata, Punching

Muda wa Uwasilishaji: 45 Siku

Jina la Bidhaa: Sahani ya chuma ya baharini

Daraja la kawaida la chuma cha Nyenzo: Mild Steel ABS GR. A B D E

Vifaa vya kawaida: 2C, 3C, 4C & 5C

Hi nguvu nyenzo chuma daraja: AH32 AH36 DH32 DH36 EH32 EH36

Hi vifaa vya nguvu: Chuma cha chini cha aloi 12MnC, 16MnC, 15MnTiC, 14MnVTiReC

Matumizi: kutumika kwa ajili ya ujenzi wa meli na utengenezaji wa muundo wa hull meli

MOQ: 300 Tani

Faida: Bei ya ushindani na ubora mzuri

Makali: 4 Kukata

Cheti: Vyeti vya vyeti vya vyeti vya darasa

Uwezo wa Ugavi: 3000 Ton/Tons kwa Siku

Ufungaji & Utoaji

Maelezo ya Ufungashaji: Bundle katika kontena au mizigo mingi

Bandari: Bandari ya Tianjin

Muda wa Kiongozi: Ili kujadiliwa$1,300.00$1,100.00 -

Soma ZaidiMwoneko Chapu

Soma ZaidiMwoneko ChapuQ195 Cathode gorofa ya chuma

Q195 cathode gorofa chuma hutumiwa kwa ajili ya electrolytic aluminium kiwanda, chuma cha chini cha kaboni kina conductivity nzuri ya umeme. Ili kuzalisha bar ya mtoza cathode ya alumini ya elektroliti ni mchakato mkali, kwa sababu mfumo wa electrowinning ni nzito DC sasa, electroconductivity itaamua gharama ya Aluminium, Kwa hivyo lazima iwe na electroconductivity nzuri sana, kuokoa matumizi ya nguvu na kuongeza ufanisi wa elektroliti.

$720.00$600.00 -

Soma ZaidiMwoneko Chapu

Soma ZaidiMwoneko ChapuAngle bar kwa ajili ya maambukizi mnara kufanya au baharini meli kujenga

Upau wa pembe, Pia inajulikana kama L-bar au chuma cha pembe, ni sehemu ya kawaida ya chuma ya muundo katika ujenzi wa minara ya maambukizi na ujenzi wa meli ya baharini.

Katika ujenzi wa minara ya maambukizi, Baa za pembe hutumiwa kama wanachama muhimu wa muundo kutoa utulivu na msaada. Mara nyingi hutumiwa kama vitambaa, mikono ya msalaba, na washiriki wa diagonal kuhimili mizigo na vikosi mbalimbali ambavyo mnara unaweza kupata, kama upepo, Barafu, na uzito wa mistari ya maambukizi. Baa za Angle huchaguliwa kwa nguvu zao, Versatility, na gharama nafuu katika maombi haya.

Katika ujenzi wa meli ya baharini, Baa za pembe pia hutumiwa sana. Inatumika kwa matumizi mbalimbali kama vile kutengeneza, Kukaza, na miundo ya kusaidia. Baa za Angle hutoa uadilifu wa muundo na utulivu kwa hull ya meli na muundo wa juu. Hutumiwa katika ujenzi wa vichwa vingi, Muafaka, Decks, na vifaa vingine muhimu. Baa za Angle zinapendelewa katika ujenzi wa meli kwa sababu ya uwiano wao wa juu wa nguvu-kwa-uzito, Urahisi wa uzushi, na ufanisi wa gharama.$650.00$560.00 -

Soma ZaidiMwoneko Chapu

Soma ZaidiMwoneko ChapuSAE1006 bar ya chini ya chuma cha kaboni kwa umeme wa Aluminium

SAE 1006 / Q195 Alumini kuyeyuka kwa umeme wa cathode hutumiwa kwa kiwanda cha aluminium ya umeme, chuma cha chini cha kaboni kina conductivity nzuri ya umeme. Ili kuzalisha bar ya mtoza cathode ya alumini ya elektroliti ni mchakato mkali, kwa sababu mfumo wa electrowinning ni nzito DC sasa, electroconductivity itaamua gharama ya Aluminium, Kwa hivyo lazima iwe na electroconductivity nzuri sana, kuokoa matumizi ya nguvu na kuongeza ufanisi wa elektroliti.

$720.00$600.00 -

Soma ZaidiMwoneko Chapu

Soma ZaidiMwoneko ChapuQ345B bar ya gorofa ya reli

$600.00Rail flat bar hutumiwa kwa muundo mwingi, Tunaweza kutoa vifaa na ukubwa wowote kama ombi lako, pia inaweza kuzalisha bar laini ya gorofa ya uso, Ukubwa kama hapa chini:

10x30x6000mm Q235 bar ya gorofa

20x35x6000mm Q235 bar gorofa

30x40x6000mm Q234 bar ya gorofa

(10-30)x(30-120)x6000mm Q235/Q345 bar gorofa

40x40x6000mm ST52 bar ya gorofa ya reli

60x40x6000mm ST52 bar ya gorofa ya reli

70x40x6000mm ST52 bar ya gorofa ya reli

80x40x6000mm ST52 bar ya gorofa ya reli

-

Soma ZaidiMwoneko Chapu

Soma ZaidiMwoneko ChapuSWRM8 chuma billet ni ya chuma cha chini cha kaboni

Tunaweza kutoa aina yoyote ya billets chuma kwa kiasi kikubwa na bei ya ushindani, hasa chuma maalum, kama vile: SWRH82B, SWRH62A / 72A au SWRM8.

Pandeolwa: 11m × 152mm × 152mm.

Ikiwa unahitaji, Tafadhali acha ujumbe kwetu.

-

Soma ZaidiMwoneko Chapu

Soma ZaidiMwoneko ChapuMwambaa wa mtoza Cathode

SAE 1006 bar ya cathode inapaswa kuwa chini sana chuma cha kaboni, kwa sababu chuma cha chini cha kaboni kina electroconductibility nzuri. Kwa kawaida maudhui ya kaboni yanapaswa chini ya 0.06%, nyenzo inayoitwa SAE 1006

$720.00$600.00 -

Soma ZaidiMwoneko Chapu

Soma ZaidiMwoneko ChapuSWRH82B billet ya chuma ni ya chuma cha juu cha kaboni

Tunaweza kutoa aina yoyote ya billets chuma kwa kiasi kikubwa na bei ya ushindani, hasa chuma maalum, kama vile: SWRH82B, SWRH62A / 72A au SWRM8.

Pandeolwa: 11m × 152mm × 152mm.

Ikiwa unahitaji, Tafadhali acha ujumbe kwetu.

-

Soma ZaidiMwoneko Chapu

Soma ZaidiMwoneko ChapuCathode collector bar kwa mmea wa kuyeyusha Aluminium

SAE 1006 Bar ya mkusanyaji wa Cathode hutumiwa kwa kiwanda cha aluminium cha umeme, chuma cha chini cha kaboni kina conductivity nzuri ya umeme. Ili kuzalisha bar ya mtoza cathode ya alumini ya elektroliti ni mchakato mkali, kwa sababu mfumo wa electrowinning ni nzito DC sasa, electroconductivity itaamua gharama ya Aluminium, Kwa hivyo lazima iwe na electroconductivity nzuri sana, kuokoa matumizi ya nguvu na kuongeza ufanisi wa elektroliti.

$720.00$600.00