GHDG-800 fasta kubwa flash butt reli & Mashine ya kulehemu ya turnout

$500,000.00 $300,000.00

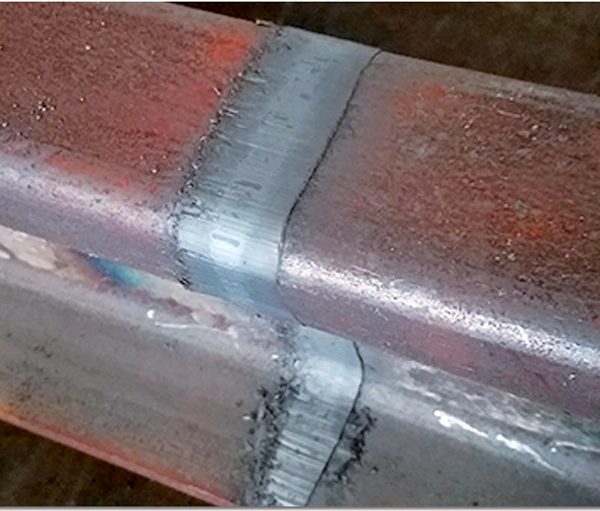

GHDG-800 fasta kubwa flash butt reli & mashine ya kulehemu ya turnout na usambazaji wa umeme wa DC, hutumiwa katika mmea uliowekwa kusuka reli fupi kwa reli za 500 mita na zaidi, au kwa weld waliojitokeza kwa reli (Kama vile vyura wa chuma wa juu), au svetsade sehemu kubwa za aloi.

Aina hii ya mashine ya kulehemu inaweza kulehemu aina yoyote ya reli na vyura, kwa usahihi pangilia reli au vyura, kuzuia kwa ufanisi reli kutoka kuteleza wakati wa kughushi kwa hasira, mara moja trim baada ya kukasirisha, na utendaji wa usambazaji wa umeme ni thabiti na sare.

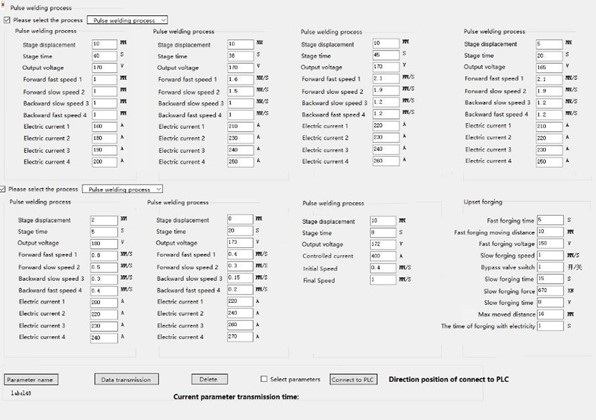

Mashine hii ya kulehemu inaweza kutambua mchanganyiko wowote wa mchakato wa kulehemu unaoendelea, mchakato wa kulehemu pulsation na mchakato wa kulehemu kabla ya joto.

- Maelezo

- Uchunguzi

GHDG-800 fasta kubwa flash butt reli & Mashine ya kulehemu ya turnout

GHDG-800 fasta kubwa flash butt reli & mashine ya kulehemu ya turnout na usambazaji wa umeme wa DC, hutumiwa katika mmea uliowekwa kusuka reli fupi kwa reli za 500 mita na zaidi, au kwa weld waliojitokeza kwa reli (Kama vile vyura wa chuma wa juu), au svetsade sehemu kubwa za aloi.

Aina hii ya mashine ya kulehemu inaweza kulehemu aina yoyote ya reli na vyura, kwa usahihi pangilia reli au vyura, kuzuia kwa ufanisi reli kutoka kuteleza wakati wa kughushi kwa hasira, mara moja trim baada ya kukasirisha, na utendaji wa usambazaji wa umeme ni thabiti na sare.

Mashine hii ya kulehemu inaweza kutambua mchanganyiko wowote wa mchakato wa kulehemu unaoendelea, mchakato wa kulehemu pulsation na mchakato wa kulehemu kabla ya joto.

GHDG-800 fasta kubwa flash butt reli & Mashine ya kulehemu ya turnout

Part A: The basic information

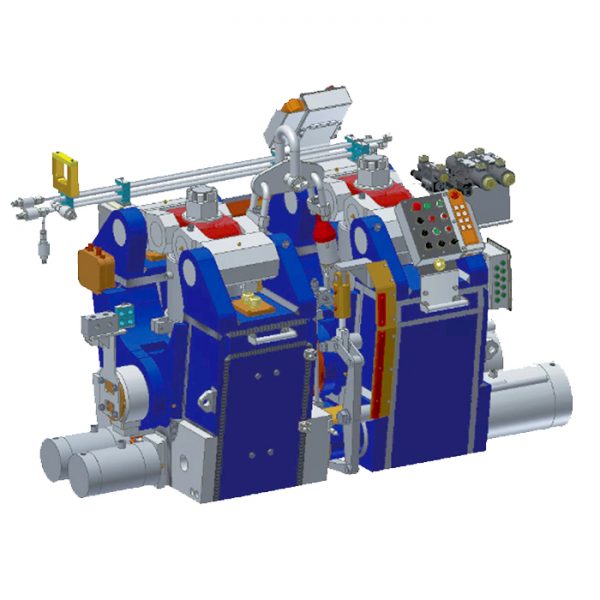

Name of the machine: Updated Fixed large Flash Butt Rail & Turnout Welding Machine

Model of the machine:DGHG-800

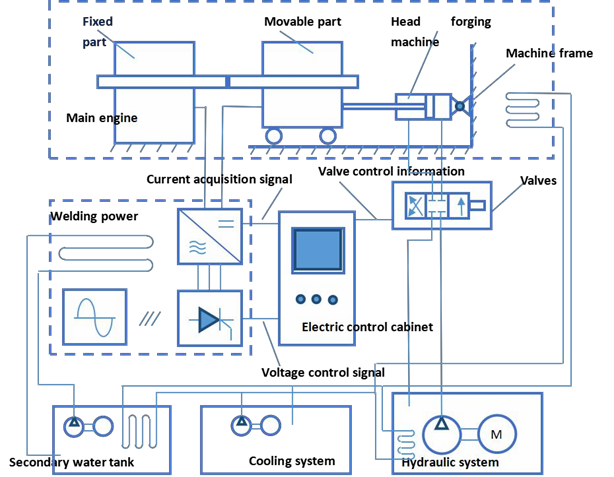

Machine composition: It is mainly composed of water-cooling system, hydraulic system, welding main circuit, electrical control system, welding head, software system and other parts.

Part B: Scope of application

This welding machine is suitable for the processing of flash butt welding of large profiles, especially for the welding of turnouts and rails.

Part C: How it works

The welding machine has four independent clamping devices, which can accurately clamp the welded workpiece with irregular cross-section and keep it horizontal. The welding machine has a centering function, which can adjust the relative position of the workpiece to be welded to complete high-precision butt welding.

During welding, a strong DC current is supplied to the workpiece to be welded through the clamping electrode, which effectively reduces the welding resistance. When the welding surface of the workpiece to be welded reaches a sufficient temperature, upsetting is performed to complete the welding. The upsetting mechanism can distribute the forging pressure on the welding surface to ensure the welding accuracy.

Part D: Welding range

Welding of turnouts and rails conforming to the national standards of China, the standard of European Union, Russian standard, the standard of United States , Nk., including the welding combination of rails and rails, rails and turnout frogs (with austenitic spacers, high-manganese steel spacers).

Weldable cross section: up to 16000 mm2

Tensile Strength: 800 – 1300 N/mm2

Welding Efficiency: max 20 joints/hour

Part E: Vigezo vya Kiufundi

E.1 Power Requirements

Power Supply voltage: 400±15V

Number of phases of power supply: 3

Frequency of power supply: 50 Hz

E.2 Transformer

Transformer capacity: 630 kVA

Maximum voltage drop: 10%

E.3 Main electrical parameters of welding machine

Transformer rated primary voltage: 400 V

Phases of primary voltage: 3

Frequency of primary voltage: 50 Hz

Auxiliary voltage: 230 V

Number of phases of auxiliary voltage: 2

Frequency of auxiliary voltage: 50 Hz

Transformer power rating: 580 kVA

Startup Duration Factor (ED): 50%

Secondary idling DC voltage: 7.7 V

Transformer Transforming Stages: 1

E.4 Technical parameters of mechanical parts

Maximum upset force : max. 1000 kN

Clamping force: max. 2000 kN

Electrode pressure: max. 1000 kN

Clamping stroke: max. 120 mm

Upset stroke: max. 50 mm

E.5 Technical parameters of hydraulic system

High pressure (pump pressure): 140 bar

Low pressure: 40 bar System pressure: 130 bar

Accumulator charge pressure: 40 bar

Volume flow with pump pressure : 190 L/min

Fuel tank capacity: 400 L

E.6 Technical parameters of water-cooling system

Water quality requirements: clean, filtered, calcium-free, neutral to low alkaline.

Flow: 150 L/min

Cooling water pressure: 4 – 6 bar

Entry water temperature: max 25 °C

Temperature Rise: 7 °C

Cooling power: 63000 kcal/h

Filtration accuracy: 100 μm

dH – value, total hardness: 9 – 15 °

dH – value, carbonate hardness: max. 9 °

pH – value: 7 – 8

Solid fraction: max. 50 mg/L

Sum of salts (sulfates/nitrates/chlorides): max. 70 mg/L

Part F Main features

*Low welding resistance for high power DC welding power is used

*Independent three-stage cooling system is used, which resulting in easy overhaul and monitor, preventing cross-contamination, and have high cooling efficiency

*High alignment accuracy for closed-loop automatic alignment is used

*With fault self-diagnosis

*With temperature detection and thermal compensation

*The multi-mechanism welding process can be used to adjust the welding process to a greater extent according to the process requirements.

Part G Structure view

Operation interface of GHDG-800 fixed large flash butt rail & Mashine ya kulehemu ya turnout