100Reli ya RE

$850.00 $800.00

- Kiwango cha: AREMA, ASTM

- Daraja: R260, R320 au 350HT

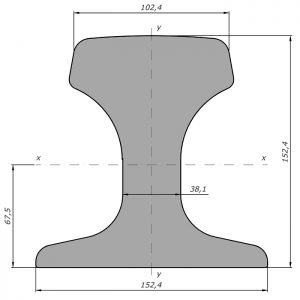

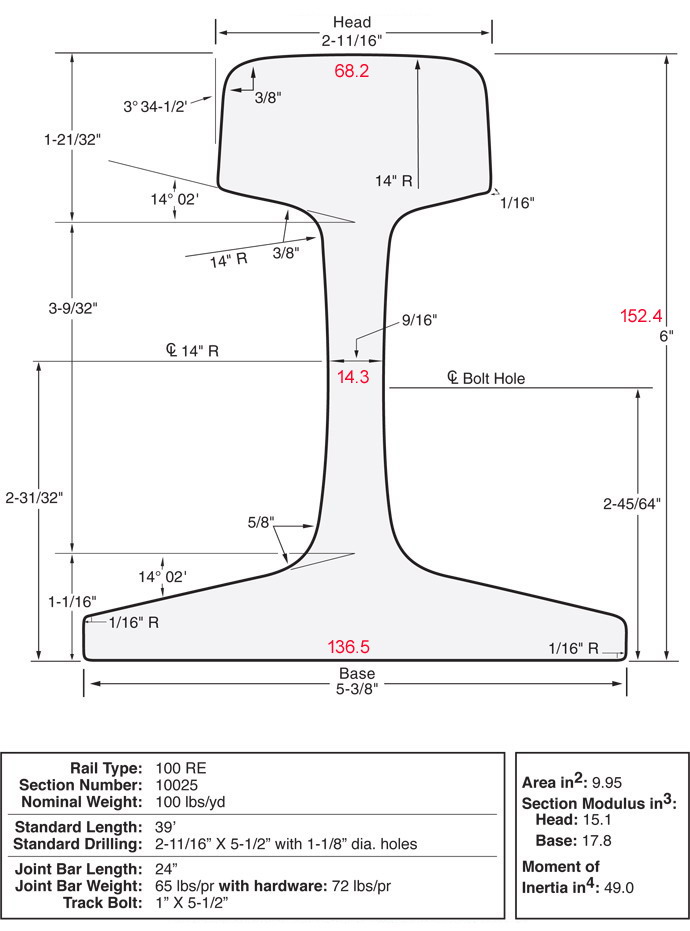

- Heigth ya Reli: 152.4mm

- Upana wa Chini: 136.5mm

- Unene wa Wavuti: 14.3mm

- Upana wa Kichwa: 68.2mm

- Urefu: 12-30m

- Namba ya Mfano: TR50 (100 TENA)

- Aina: Reli nzito

- Programu tumizi: Reli ya Reli

- Uzito: 50.35 kilo/m

- Cheti: 3.1 MTC / 3.2 na ukaguzi wa regiester wa Lloyd

- Soko: Eneo la Amerika

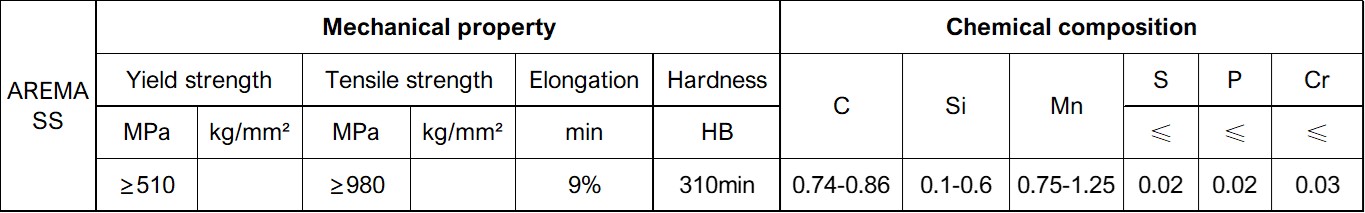

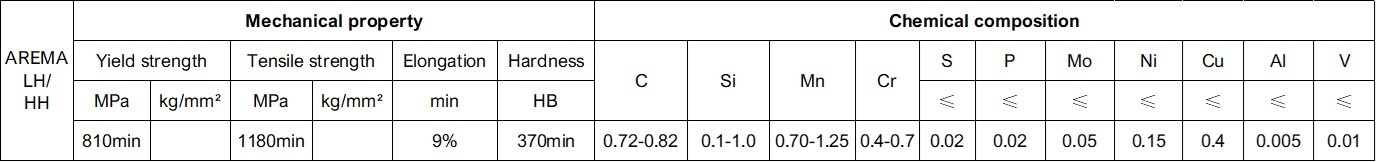

- Vifaa: 900A/ 1100

- Maelezo

- Reli ya chini ya gorofa ya kimataifa inayoweza kusafirishwa

- Kiwango cha Uzalishaji na Ukaguzi

- Uchunguzi

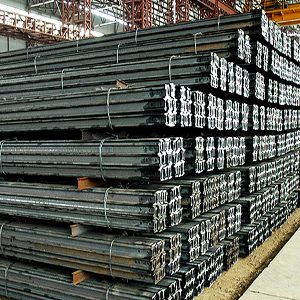

100RE rail also be named TR50 American standard heavy rail, Inatumika sana katika eneo la Amerika, Tunaweza kuizalisha kwa utaratibu, MOQ ni 500 Tani, material can be SS and HH, Urefu unaweza kuwa 39 kwa 80 Miguu.

100RE rail is a type of railway track steel rail that adheres to the standards set by the American Railway Engineering and Maintenance-of-Way Association (AREMA). It is commonly used in railway transportation systems, particularly in the United States and other countries that follow AREMA standards.

The 100RE rail is made from high-quality carbon steel, which provides it with excellent strength and hardness. The standard dimensions of the rail are 100 paundi kwa yadi (Takriban 50 kilo kwa mita) in weight. It also features a specific head shape and profile design that ensures stability and smoothness during operation.

One of the key advantages of the 100RE rail is its excellent wear resistance and impact resistance, which make it suitable for heavy loads and high-speed operations. Hayo, it has good welding and processing properties, Fanya iwe rahisi kuinstall na kuitunza.

The 100RE rail is widely used in various railway transportation systems, ikiwa ni pamoja na reli kuu, Reli ya madini, Reli ya Viwanda, and more. Its versatility and durability make it an ideal choice for railway operators who require reliable and long-lasting track infrastructure.

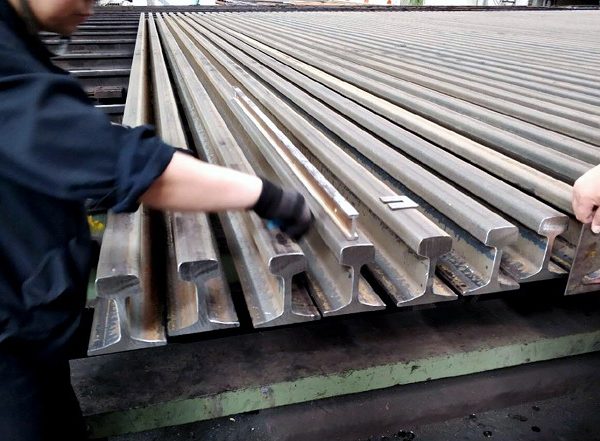

In terms of manufacturing process, the production of 100RE rail involves several steps, including steelmaking, Rolling, Matibabu ya joto, and finishing. High-quality raw materials are selected and melted in a furnace before being rolled into the desired shape and size. The rail is then subjected to heat treatment processes such as quenching and tempering to enhance its mechanical properties.

To ensure the quality and safety of the 100RE rail, rigorous testing and inspection procedures are carried out at various stages of production. These tests include non-destructive testing methods such as ultrasonic testing, magnetic particle testing, and radiographic testing, as well as destructive testing methods like tensile testing and bend testing.

Jumla, the 100RE rail is a high-performance railway track steel rail that offers excellent durability, Kuegemea, na utendaji. Kama muuzaji wa Kichina, we can provide high-quality 100RE rail and other types of railway track products to meet the needs of different customers. If you are interested in learning more about our products or obtaining a quote, Tafadhali jisikie huru kuwasiliana nasi.

Standard EN 13674 - 1:2003 Ina sehemu kuu mbili:

− Mtihani wa kufuzu na vipimo vya kukubalika

Vipimo vya kufuzu ni baadhi ya vipimo vingine ambavyo awali vilifanyika, kama kwa mfano, Kuvunjika kwa ugumu. Vipimo vya kukubalika vinaonyesha mali ya vipimo vilivyoagizwa, ambayo inahakikisha uzalishaji wa reli zenye ubora wa hali ya juu, na mahitaji ya upimaji wa utawala wa reli.

Ubora wa reli unategemea maadili yaliyopimwa ya ugumu, ambayo walianzisha lebo mpya za reli za chuma.

Vipimo vya kufuzu

Upimaji wa sifa lazima ufanyike angalau moja katika miaka mitano na kubwa

Mabadiliko katika teknolojia, Reli za uzalishaji. Mafadhaiko ya ziada ya kupima mabaki yabebwa

nje juu ya aina zote za reli za chuma kila baada ya miaka miwili upeo, ilimradi kwamba longitudo

Kiwango cha shida katika reli kinaweza kufikia hadi 250 MPa.

Mtihani wa kufuzu uliowekwa ni ufuatao:

− kuvunjika kwa ugumu

− Kiwango cha ukuaji wa uchovu

− Upimaji wa uchovu

− Mkazo wa mabaki katika mguu wa reli

− tofauti ya mstari wa katikati

− nguvu ya tensile na elongation

− ubaguzi

− mahitaji mengine ya kufuzu

Vipimo vya kukubalika

Ndani ya upimaji wa kukubalika hufanywa mfululizo wa vipimo vya maabara kama vile:

− muundo wa kemikali (maudhui ya juu ya vipengele vifuatavyo: H, O, Al, V, Elementi za N na oligo)

− microstructure (Kuongezeka kwa X 500)

− shahada ya decarburizing charred layer (inaruhusiwa hadi 0.25 mm)

− usafi wa chuma (Hasa uwepo wa oksidi)

− macrostructure (Mtihani wa Baumann)

− ugumu

− nguvu ya tensile

Reli nyingine za upimaji wa kukubalika ni:

− uvumilivu wa vipimo

− vigezo (template ya kudhibiti)

− Mahitaji ya ukaguzi / uvumilivu kwa ubora wa ndani na ubora wa uso

Hali ya ndani inachunguzwa ultrasound katika udhibiti wa mchakato endelevu, na inajumuisha angalau 70% ya kichwa na angalau 60% Wavuti.

- Kiwango cha UIC 860 V: 1996 - imeagizwa aina nne reli ya chuma ya pearlite katika anuwai ya nguvu ya tensile kutoka 700 kwa 1300 MPa.

- Standard EN 13674 - 2003, hutoa aina saba za ugumu wa chuma cha pearlite katika anuwai 200 kwa 390 HBV, aina ya chuma kulingana na EN 13674, kulingana na maadili ya ugumu (R 200, R 220, R 260, R 260 Mn, 320 Cr, 350 HT, 350 LHT).