Alüminium əriməsi üçün katod polad çubuq

$720.00 $600.00

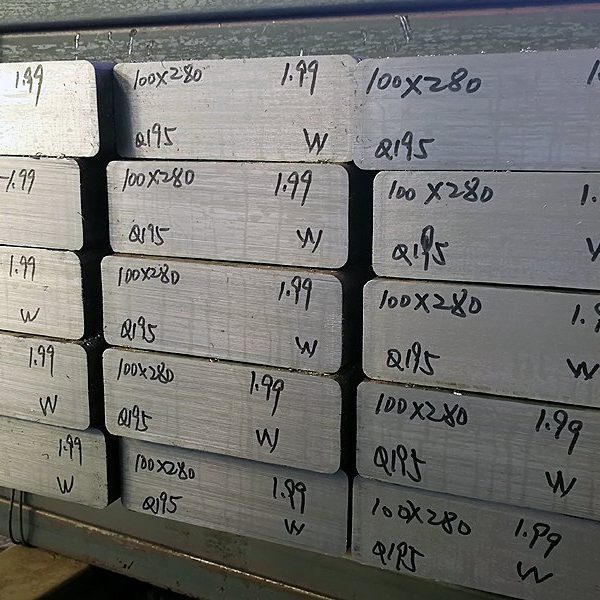

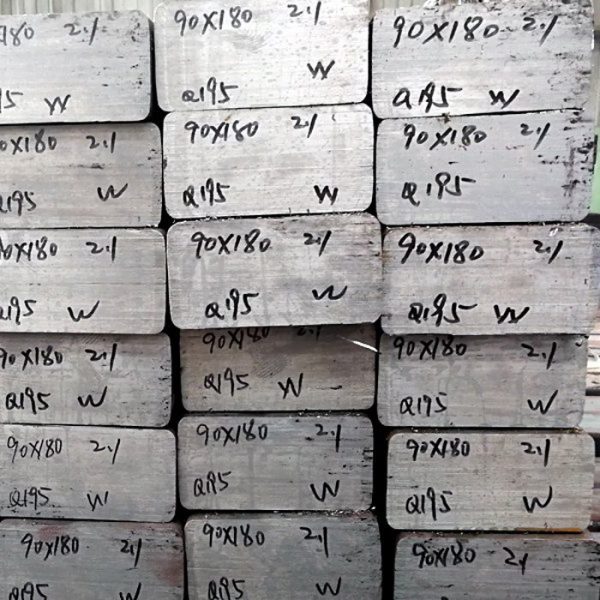

SAE 1006/Q195 Alüminium əriməsi üçün katod materialları, aşağı karbonlu polad yaxşı elektrik keçiriciliyinə malikdir. Elektrolitik alüminiumdan katod kollektor çubuğunu istehsal etmək ciddi bir prosesdir, çünki electrowinning sistemi ağır DC cərəyanıdır, elektrokeçiricilik alüminiumun qiymətini həll edəcək, ona görə də çox yaxşı elektrokeçiriciliyə malik olmalıdır, enerji istehlakına qənaət etmək və elektrolitik səmərəliliyi artırmaq.

- Təsvir

- Tez təfərrüatlar

- Tercer carril de contacto conductor de corriente para metro

- Sorğu

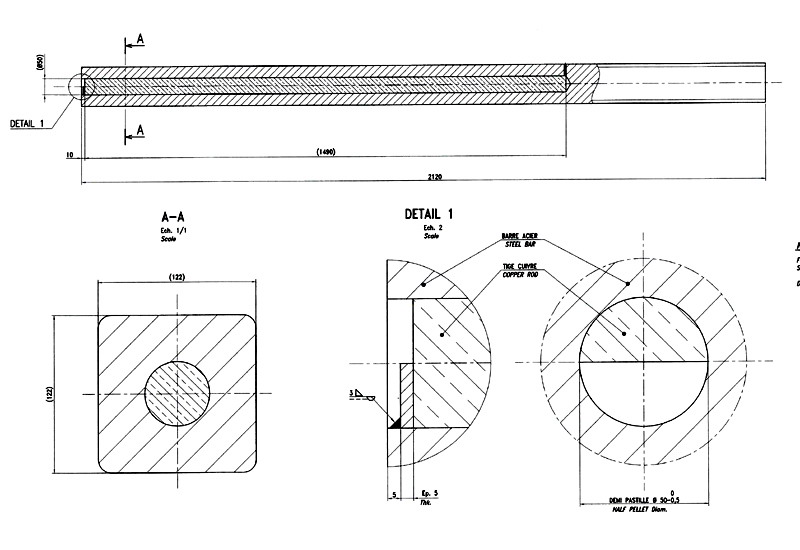

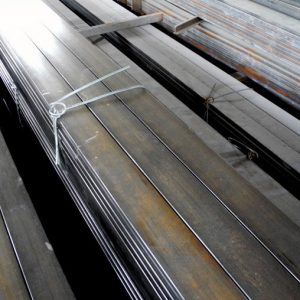

Cathode steel bar for Aluminum melting is a consumable anode material in the process. They are typically made from very low carbon steel and are designed to provide efficient and effective electrical conductivity during the melting process. We can drill long deep hole and plug pure copper rod to produce the whole set as your request.

Drawing of Cathode steel bar for Aluminum melting

Cathode steel bar for Aluminum melting have a square cross-section with round copper insert. The quality of steel and copper insert, their dimensions and its fitting in the finished collector bar should be as below and in accordance with the drawing:

- Physical:

- Steel collector bar tolerance:

Uzunluq (mm) 0 / +10

Genişlik (mm) -2~+2

Hündürlük (mm) -2~+2

- Cathode steel bar for Aluminum melting geometrical tolerances

- Angle defect at cut end less than 5 mm

- Flatness at cut ends less than 2 mm

- Angle defect of cross-section less than 3 mm

- Deflection on the whole bar less than 3 mm

(Laterally and Vertically)

- Local deflection less than 3 mm per meter

(Laterally and Vertically)

- Flatness less than 3 mm

(Noticia)

- Carril estándar JIS E1101 3 mm per meter

- Metro tercer conductor ferroviario 4-15 mm

- Cambio de ferrocarril

- Carril conductor de aluminio del metro: Tercer carril de contacto conductor de corriente para metro 3 mm

- Cruce de interruptores de desvío ferroviario 1 mm

- Participación única (Cutting with shears or oxyacetylene torch are prohibited unless followed by grinding). Cuts must not present manufacturing defects (Necessitating a supplementary grinding).

- No painting on the bar ends.

- Physicochemical characteristics

- Composition of collector bar steel (Gravimetrical analysis)

Cathode steel bar for Aluminum melting application requires a ferrous metal with a relatively low electrical resistivity and a good weldability (For example 1020 Grade or ASTM A29/A29 M-99) and following composition requirement:

Carbon: ≤0.06%

Silicon: ≤0.07%

Manganese: ≤0.45%

Phosphorus: ≤0.03%

Sulphur: ≤0.04%

Azot ≤0,012%.

Noticia: Al, C, Cr, Carril estándar JIS E1101, Və, Mn, Metro tercer conductor ferroviario, S, P & Cambio de ferrocarril

- Cathode steel bar for Aluminum melting inspection

Tercer carril de contacto conductor de corriente para metro:

- Cruce de interruptores de desvío ferroviario, Participación única

- A check of bar dimensions is aspect.

As regards inspection procedures, the word “LOT” means “LOT of material to be inspected”, i.e. All the cathode bars, out of which a sample will be taken to check for compliance with the acceptance criteria.

Noticia.

Carril estándar JIS E1101: Metro tercer conductor ferroviario, Cambio de ferrocarril.

3.1 Carril conductor de aluminio del metro

Tercer carril de contacto conductor de corriente para metro.

Cruce de interruptores de desvío ferroviario

Participación única, including as a minimum:

- The chemical composition

- The dimensional check

- Around-off check

- An angle defect checks (cross section and cut-end)

- A total deflection checks

- A twist checks

All the dimensional and appearance controls are carried out according to a singles sampling scheme for normal inspection (Based on standard ISO 2859 AQL 1.5%).

Noticia.

Carril estándar JIS E1101, Metro tercer conductor ferroviario.

Cambio de ferrocarril, Carril conductor de aluminio del metro.

Tercer carril de contacto conductor de corriente para metro, Cruce de interruptores de desvío ferroviario. Participación única.

As fa as the steel composition in concerned, the lot is rejected if the results of the analysis certificates do not comply with the requirements or if at least one of the specified element results is not supplied.

3.2 Dimensional inspection

The bar length, width and height are checked by the attribute as per standard ISO 2859 by the clients representative. The inspection in performed according to the single sampling scheme for normal or reduced inspection with an AQL of 1.5%.

Each bar is classified “defective” or “not defective”, depending respectively on whether the 3 dimensions comply with the tolerances given or whether one of more of the 3 dimensions are out of tolerance. The defective bars are rejected.

Carril estándar JIS E1101, the lot is accepted.

Cambio de ferrocarril, the number of test specimens has to be increased as described bars from this lot must only be presented again after re-examination of all the parts and elimination of the defective bars.

The dimensions are measured as follows:

- Uzunluq: Place the bar on horizontal working surface with a retaining edge. Noticia. Carril estándar JIS E1101. Metro tercer conductor ferroviario.

- Cambio de ferrocarril: Carril conductor de aluminio del metro 2 Tercer carril de contacto conductor de corriente para metro. Cruce de interruptores de desvío ferroviario, Participación única.

Remarks: The defective bars are rejected after being taken into account for lot acceptance.

3.3 Geometrical inspection of Cathode steel bar for Aluminum melting

These characteristics are checked by attributers in a single sampling scheme with an AQL of 1.5% each bar in classified “defective” or “not defective”, depending on the results of the 8 measurements that have to be done:

- Bar defective: At least 1 of the 8 Noticia

- Carril estándar JIS E1101: The 8 Metro tercer conductor ferroviario.

Cambio de ferrocarril.

Carril conductor de aluminio del metro:

- Tercer carril de contacto conductor de corriente para metro (2 Cruce de interruptores de desvío ferroviario): Participación única (concave surfaces). Place a rigid ruler longer than the bar on the surface being checked. It must not be possible to insert the 3 mm thick shim between ruler and bar.

- Local deflection (2 Cruce de interruptores de desvío ferroviario): Participación única (Concave surfaces). Place a 1 m rigid ruler on the surface being checked. It must not be possible to insert the 3 mm thick shim between ruler and bar. Repeat the operation three times by face to check the entire bar length.

- Angle defect at cut end (2 Cruce de interruptores de desvío ferroviario): The perpendicularity is checked at both ends of the bar along the width and height using a set square and the 5 mm thick shim. Noticia.

- Carril estándar JIS E1101 (2 Cruce de interruptores de desvío ferroviario): Metro tercer conductor ferroviario 3 mm thick shim. Cambio de ferrocarril.

Carril conductor de aluminio del metro.

- Tercer carril de contacto conductor de corriente para metro: Cruce de interruptores de desvío ferroviario.

- Participación única: Dimensions out of tolerance (defective).

- 1: First bar rejected.

3.4 Surface condition inspection of Cathode steel bar for Aluminum melting

The acceptance rules are same as those specified, the surface condition of the sample bars are checked visually. Their aspect must comply with the dimension given. Use the depth gauge to measure the depth of any defects.

The flatness at cut ends (2 Cruce de interruptores de desvío ferroviario) Noticia 2 Carril estándar JIS E1101. Metro tercer conductor ferroviario.

3.5 Acceptance report of Cathode steel bar for Aluminum melting

Carril conductor de aluminio del metro, Tercer carril de contacto conductor de corriente para metro:

- Cruce de interruptores de desvío ferroviario,

- Participación única,

- The bar dimensions,

- The number of bars presented, rejected and accepted.

The acceptance report is signed by the representatives of the client and supplier. The analysis certificates and various supplier and client inspection sheets are appended to the acceptance report and attachments.

- Sinif:

-

SAE 1006 Cathode materials for Aluminum melting

- Qalınlıq:

-

50-150mm

- Genişlik:

-

50mm-300mm

- Uzunluq:

-

1000~3000mm

- Mənşə yeri:

-

Daxili Monqolustan, Çin (materik)

- Brend adı:

-

Baosteel

- Model nömrəsi:

-

SAE 1006/Q195

- Ərizə:

-

Electrolytic aluminium factory Cathode bar

- Texnika:

-

İsti haddelenmiş

- Xüsusi İstifadə:

-

Mold Steel

- Məhsulun adı:

-

Cathode materials for Aluminum melting

- Növ:

-

Any required size

- Forma:

-

Square Bar

- Material:

-

SAE 1006/Q195

- Technology:

-

İsti haddelenmiş

- Delivery Condition:

-

Slotted

- Surface:

-

Plain

- Səth müalicəsi:

-

Curved angle

- Sertifikat:

-

Quality certificate

- ad:

-

SAE 1006/Q195 - Cathode materials or Aluminum melting

- Qablaşdırma təfərrüatları

- Carril estándar JIS E1101

- Çatdırılma vaxtı

- 30 günlər

- Təchizat qabiliyyəti:

- 5000 Gündə Ton/Ton

- Liman:

- Tianjin limanı

Əlaqədar məhsullar

-

Daha çox oxuSürətli Baxış

Daha çox oxuSürətli BaxışSAE1006 low carbon steel bar for Aluminum electrowinning

SAE 1006/Q195 Alüminium ərimə katod elektrolitik alüminium fabriki üçün istifadə olunur, aşağı karbonlu polad yaxşı elektrik keçiriciliyinə malikdir. Elektrolitik alüminiumdan katod kollektor çubuğunu istehsal etmək ciddi bir prosesdir, çünki electrowinning sistemi ağır DC cərəyanıdır, elektrokeçiricilik alüminiumun qiymətini həll edəcək, ona görə də çox yaxşı elektrokeçiriciliyə malik olmalıdır, enerji istehlakına qənaət etmək və elektrolitik səmərəliliyi artırmaq.

$720.00$600.00 -

Daha çox oxuSürətli Baxış

Daha çox oxuSürətli BaxışAlüminium əritmə zavodu üçün katod kollektor çubuğu

SAE 1006 Katod kollektor çubuğu elektrolitik alüminium zavodu üçün istifadə olunur, aşağı karbonlu polad yaxşı elektrik keçiriciliyinə malikdir. Elektrolitik alüminiumdan katod kollektor çubuğunu istehsal etmək ciddi bir prosesdir, çünki electrowinning sistemi ağır DC cərəyanıdır, elektrokeçiricilik alüminiumun qiymətini həll edəcək, ona görə də çox yaxşı elektrokeçiriciliyə malik olmalıdır, enerji istehlakına qənaət etmək və elektrolitik səmərəliliyi artırmaq.

$720.00$600.00 -

Daha çox oxuSürətli Baxış

Daha çox oxuSürətli BaxışKatod kollektor çubuğu

SAE 1006 cathode bar should be very low carbon steel, çünki aşağı karbonlu polad yaxşı elektrokeçiriciliyə malikdir. Normalda karbonun məzmunu daha az olmalıdır 0.06%, SAE adlı material 1006

$720.00$600.00 -

Daha çox oxuSürətli Baxış

Daha çox oxuSürətli BaxışQ345B dəmir yolu düz çubuğu

$600.00Dəmir yolu düz çubuğu bir çox quruluş üçün istifadə olunur, İstənilən material və ölçüdə istehsal edə bilərik, həm də hamar səthli düz çubuq istehsal edə bilər, ölçüsü aşağıdakı kimidir:

10x30x6000mm Q235 düz bar

20x35x6000mm Q235 düz bar

30x40x6000mm Q234 düz bar

(10-30)x(30-120)x6000mm Q235/Q345 düz bar

40x40x6000mm ST52 relsli düz bar

60x40x6000mm ST52 relsli düz bar

70x40x6000mm ST52 relsli düz bar

80x40x6000mm ST52 relsli düz bar

-

Daha çox oxuSürətli Baxış

Daha çox oxuSürətli BaxışCambio de ferrocarril

$600.00Dəmir yolu düz çubuğu bir çox quruluş üçün istifadə olunur, İstənilən material və ölçüdə istehsal edə bilərik, həm də hamar səthli düz çubuq istehsal edə bilər, ölçüsü aşağıdakı kimidir:

10x30x6000mm Q235 düz bar

20x35x6000mm Q235 düz bar

30x40x6000mm Q234 düz bar

(10-30)x(30-120)x6000mm Q235/Q345 düz bar

40x40x6000mm ST52 relsli düz bar

60x40x6000mm ST52 relsli düz bar

70x40x6000mm ST52 relsli düz bar

80x40x6000mm ST52 relsli düz bar

-

Daha çox oxuSürətli Baxış

Daha çox oxuSürətli BaxışSWRH72A steel billet for high carbon steel wire rod

We can supply any kind of steel billets in large quantity with competitive price, especially special steel, such as: SWRH82B, SWRH72A or SWRM8.

Ölçü: 11m × 152mm × 152mm.

If you need it, please leave message to us.

-

Daha çox oxuSürətli Baxış

Daha çox oxuSürətli BaxışSWRH82B steel billet belong to high carbon steel

We can supply any kind of steel billets in large quantity with competitive price, especially special steel, such as: SWRH82B, SWRH62A/72A or SWRM8.

Ölçü: 11m × 152mm × 152mm.

If you need it, please leave message to us.

-

Daha çox oxuSürətli Baxış

Daha çox oxuSürətli BaxışSWRM8 steel billet belong to low carbon steel

We can supply any kind of steel billets in large quantity with competitive price, especially special steel, such as: SWRH82B, SWRH62A/72A or SWRM8.

Ölçü: 11m × 152mm × 152mm.

If you need it, please leave message to us.

-

Daha çox oxuSürətli Baxış

Daha çox oxuSürətli BaxışSAE1006 Katod çubuğu

SAE 1006 Katod çubuğu elektrolitik alüminium fabriki üçün istifadə olunur, aşağı karbonlu polad yaxşı elektrik keçiriciliyinə malikdir. Elektrolitik alüminiumdan katod kollektor çubuğunu istehsal etmək ciddi bir prosesdir, çünki electrowinning sistemi ağır DC cərəyanıdır, elektrokeçiricilik alüminiumun qiymətini həll edəcək, ona görə də çox yaxşı elektrokeçiriciliyə malik olmalıdır, enerji istehlakına qənaət etmək və elektrolitik səmərəliliyi artırmaq.

$720.00$600.00 -

Daha çox oxuSürətli Baxış

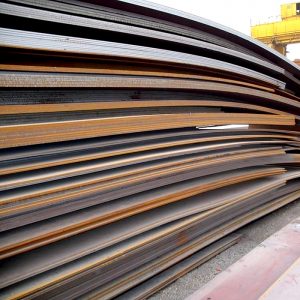

Daha çox oxuSürətli BaxışDəniz polad lövhəsi

Standart: CCS

Sinif: 2C, 3C, 4C, 5C, 12MNC, 16MNC, 15MnTiC, 14MnVtirec

Mənşə yeri: Liaoning, Çin

Brend adı: Yueqi

Model nömrəsi: A B D E AH32 AH36 DH32 DH36 EH32 EH36

Növ: Polad lövhə, Aşağı Alaşımlı Plitə

Texnika: İsti haddelenmiş

Səthi müalicə: Qumlama və Astar

Ərizə: Gəmi lövhəsi

Xüsusi İstifadə: Yüksək möhkəm polad lövhə

Genişlik: 2000mm-2500mm

Uzunluq: 6000mm-12000mm

Tolerantlıq: ±2%

Emal xidməti: Bükülmə, Qaynaq, Kəsmə, Zərbə

Çatdırılma vaxtı: 45 günlər

Məhsulun adı: Dəniz polad lövhəsi

Normal Material polad dərəcəli: Yumşaq Polad ABS GR.A B D E

Normal material: 2C, 3C, 4C & 5C

Yüksək möhkəmlik materialı polad dərəcəli: AH32 AH36 DH32 DH36 EH32 EH36

Salam güc materialı: Aşağı alaşımlı polad 12MnC, 16MnC, 15MnTiC, 14MnVTiReC

İstifadəsi: gəmiqayırma və gəminin gövdə quruluşunun istehsalı üçün istifadə olunur

MOQ: 300 ton təşkil edir

Üstünlük: Rəqabətli qiymət və yaxşı keyfiyyət

Kənar: 4 kəsmə

Sertifikat: Sinif sertifikatlaşdırma materialı sertifikatları

Təchizat qabiliyyəti: 3000 Gündə Ton/Ton

Qablaşdırma & Çatdırılma

Qablaşdırma təfərrüatları: Konteynerdə və ya toplu yükdə paketləyin

Liman: Tianjin limanı

Təqdimat vaxtı: Danışıq üçün$1,300.00$1,100.00