KEPERLUAN BARU UNTUK KUALITI REL KELULI

Abstract

Rails are an important part of the railway infrastructure. Kualiti rel mempunyai kesan langsung untuk fungsi lalu lintas kereta api. Meningkatkan kelajuan kereta api, high frequency of traffic and axle load wagons and locomotives is directly related to the quality of rails. The characteristic quality tracks are prescribed standards of the International Union Railway (published UIC and EN 13674).

In order to increase the competitiveness of rail transport compared to other forms of transport and establishment of interoperable railway system of the European Union, is obligate to establish system management quality in according to ISO 9001. Also new standard EN 13674 establish other types steels of rails (seven types pearlite steels) and introduces a new philosophy in the micro and macro composition of steel for rails.

Pengenalan

The railway infrastructure is a tracks with all the appropriate facilities plants and other devices, which are in function at the railway traffic.

Rails as an important part of the railway infrastructure have exactly level of quality. In Europe, the quality of rails is prescribed by international standards, the European Union of Railways UIC 860 and EN13674.

In other vital parts of railway infrastructure in order to: increase the speed of trains, increasing the axles loads of trains and locomotives traction and increasing the density of traffic and increase resistance to harmful influences of the environment (environmental aspects), required and improve the quality of rails.

The European Union standards for railways (UIC) have agreed national standards of different countries.

The quality of tracks, measures and tolerances are prescribed standards SRPS.C.K1.020 and SRPS.C.K1.021.

These standards clarify in detail the most important components of quality tracks, production of steel for rails, and to control the final delivery of new rails.

Depending on load rails in service are set levels of quality tracks, with the aspect tensile strength and ductile properties. Depending on the degree exploitation load rails, rails are divided into two main groups, namely:

– rail and normal quality

– wear resistant rails (rails with high resistance to abrasion).

Demands for quality rails, metal-in during production steel rails, emphasis given to the following adjustment in the production of rails:

– Increased the mass of the rail due to the meter 45 Untuk 77 Kg / m. Now the most used rails with a mass 60 (Fig. 1) the prescribed weight of 60,34 Kg / m, represented by former rail profile 49 Kg / m prescribed weight 49,43 Kg / m (Fig. 2).

– Increase the value of tensile strength from 700 Untuk 1300 Mpa.

– Increasing the purity of steel especially sulfur and phosphorus from the previous maximum of 0,050 Untuk 0,030%.

Production of long rails up to 120 m in length (decreasing the number of welded joints and dilatation spaces). [1], [4]

Macrostructure i. e. the consistency of the material is checked by Baumann test.

For Baumann test can be seen the level of expressed macro segregation, which is in direct correlation with low soluble micro constituents layout (Fig 3).

Fig. 3 Strong segregation block at the intersection of rails

Prescribed properties for steel of rails

Requirements of UIC 860 V

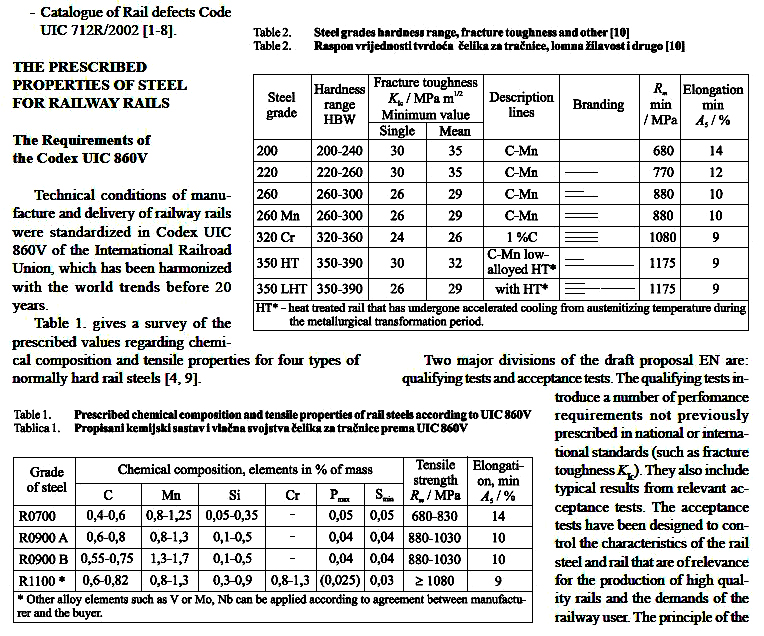

For a selection of different types of rails, the corresponding chemical composition and mechanical property requirements are presented in (Jadual 1) according to standard UlC 860 – 1.

From the Table it is obvious that, in the case of wear – resistant rails, increased carbon (C) dan mangan (Mn) content is responsible for the improved mechanical properties. The increase in wear resistance is based on a theory of the mutual influence of certain elements. Carbon influences the mechanical properties through the volume fraction of cementite and the content of pearlite. Manganese influences the temperature decrease of the eutectoid reaction and the fineness of pearlite lamellae, itu adalah, the reduction in the interlamellar distance. As an illustration of the influence of alloying elements, seperti karbon, manganese and silicon, on wear speed for a pearlite structure.

where:

W – represents the speed of wear expressed as volume loss per unit of path over which sliding occurs, C, Mn, Si – represent the percentage contents of carbon, manganese and silicon respectively.

For all rail types, the appropriate values of mechanical properties are also laid down and controlled by the Standard (Jadual 1).

In pearlitic steels, the structure of which is depicted in (Fig. 4). The mechanical properties are largely governed by the distance between the cementite (Fe3C) lamellae, their thickness and by the grain size. The influence of the interlamellar spacing on yield point, tensile strength and reduction of area is demonstrated by the structures shown in (Fig. 5). These examples display microstructures of the same steel subjected to different cooling rates. The same effect can be achieved by controlling the diffusion rate via the alloying contents. [1]

The new European standard EN 13674, which deals with issues of quality rail, takes into account the increasing demands for safety and economy of railway traffic.

European standard EN 13674 includes symmetrical rails with wide rate of mass ≥46 kg/m.

This standard was developed by the European Committee for Standardization CEN (European Committee for Standardization) of the National Committee of the 19 countries. This standard has built a modern approach to the issue of quality tracks with the recommendation that manufacturers should be required tracks have introduced quality management system in accordance with the requirements of ISO 9001 Piawaian.

Standard EN 13674 – 1:2003 terdiri daripada dua bahagian utama:

- ujian kelayakan dan

- ujian penerimaan

Ujian kelayakan adalah beberapa ujian lain yang sebelum ini dijalankan, sebagai contoh, ketangguhan patah. Ujian penerimaan mencirikan sifat ujian yang ditetapkan, yang memastikan pengeluaran rel berkualiti tinggi, dan keperluan ujian pentadbiran kereta api (Jadual 2) Dan (Jadual 3).

Kualiti rel adalah berdasarkan nilai kekerasan yang diukur, di mana mereka memperkenalkan label baru untuk rel keluli.

Ujian kelayakan

Qualification testing must be conducted at least one in five years and the major changes in technology, rel pengeluaran. Additional testing residual stresses are carried out on all types of steel rails every two years maximum, provided that the longitudinal strain rate in the rails can amount to up to 250 Mpa.

Peperiksaan kelayakan yang ditetapkan adalah seperti berikut:

− ketangguhan patah

− keletihan retak kadar pertumbuhan

− ujian keletihan

− tekanan sisa dalam kaki kereta api

− variasi garis tengah

− kekuatan tegangan dan pemanjangan

− pengasingan

− keperluan kelayakan lain

Ujian penerimaan

Dalam ujian penerimaan dijalankan satu siri ujian makmal seperti:

− komposisi kimia (kandungan maksimum unsur-unsur berikut: H, O, Al,

V, Unsur N dan oligo)

− mikrostruktur (meningkatkan x 500)

− darjah lapisan hangus decarburizing (dibenarkan sehingga 0.25 Mm)

− kesucian keluli (terutamanya kehadiran oksida)

− makrostruktur (Ujian Baumann)

− kekerasan

− kekuatan tegangan

Rel ujian penerimaan lain adalah:

− toleransi dimensi

− kriteria (templat kawalan)

− keperluan pemeriksaan / toleransi untuk kualiti dalaman dan kualiti permukaan

Keadaan dalaman diperiksa ultrasound dalam kawalan proses berterusan, Dan

includes at least 70% kepala dan sekurang-kurangnya 60% Web.

Jadual 2. Chemical composition/mechanical properties (according to the standards EN

13674-1:2003)

Conclusions

Based on insight into the current national international documents that regulate

the quality of tracks and access to the existing situation in the Serbian Railways can

conclude the following:

– In order to increase functionality, and safety of railway traffic, the rails as part of the

railway infrastructure, are paid special attention to the aspect of continuous

improvement of their quality.

– Standard of UIC 860 V: 1996 – prescribed four types pearlite steel rails in the range

of tensile strength from 700 Untuk 1300 Mpa.

– Standard EN 13674 – 2003, menyediakan tujuh jenis kekerasan keluli pearlite dalam julat

200 Untuk 390 HBV, jenis keluli mengikut EN 13674, based on the values of

Kekerasan (R 200, R 220, R 260, R 260 Mn, 320 Cr, 350 HT, 350 LHT).

– According to the requirements of new European standards for rails, Kereta api

manufacturer is obliged to harmonize its procedures with the procedural

requirements of the standard EN ISO 9001: 2000.

– According to standard EN 13674 is introduce qualifying tests due to check of

Pengeluar

– Acceptance test appear new requirements for the quality of tracks such as:

- ketangguhan patah

- measurement of crack propagation

- Fracture Mechanics

- continuous ultrasound control rails (70% heads and 60% Web)

- Holders of higher tensile strength and hardness of the rails are chemical

elements: Karbon, manganese and chromium, and also prescribed the

maximum value of residual elements in steel, which greatly reduce ductile

properties.