Reli ya chuma ya TR30

$700.00 $660.00

Kiwango cha: ASTM, BS, GB, JIS

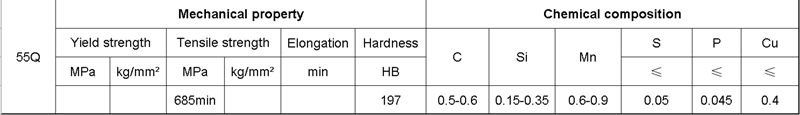

Daraja: Q235B / 55Q

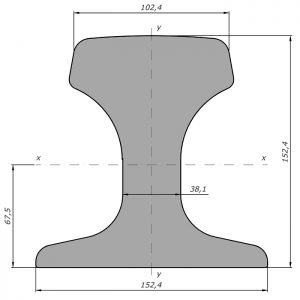

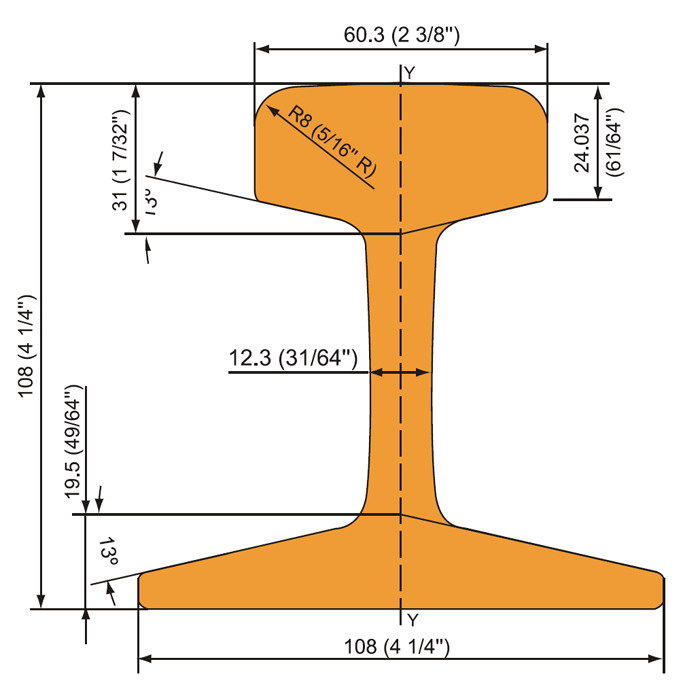

Heigth ya Reli: 108mm

Upana wa Chini: 108mm

Unene wa Wavuti: 12.3mm

Upana wa Kichwa: 60.33mm

Urefu: 6m/8m/10m

Mahali pa Asili: Hebei, China (Bara)

Jina la Chapa: Hangang

Namba ya Mfano: TR30

Aina: Reli ya Mwanga

Programu tumizi: Reli ya Reli

Uzito: 30.1kilo/m

Sekondari au La: Isiyo ya sekondari

Kipenyo cha Shimo la Bolt: 24mm

Jina: TR30 Amerika standard mwanga chuma reli

Jina la bidhaa: 30reli ya chuma ya kg / m lignt

Jina lingine: Reli ya madini

Flange urefu wa katikati: 19.45mm

Urefu wa kichwa: 30.95mm

Soko: Nchi zinazoendelea

Matumizi: Gari la mgodi linaloendesha reli

Cheti: ISO9001:2008

Mali: TR30 Amerika standard mwanga chuma reli

MOQ: 20 Ton/Tons

- Maelezo

- Producing and inspection standard

- Reli ya chini ya gorofa ya kimataifa inayoweza kusafirishwa

- Uchunguzi

TR30 steel rail is used for mine railroad line or light rail track, Daima tuna hisa hii, Inaweza kuitoa kwa wakati. Vifaa vina Q235 na 55Q, urefu wa 6m, 8m na 10m.

TR30 steel rail is a type of steel rail used in railway tracks. It is primarily used in light rail transit (LRT) systems and urban transportation networks. ya “TR” in TR30 stands for “Transit Rail,” indicating its specific application in transit systems.

TR30 rail is designed to meet the requirements of light rail transit, which typically involves lower axle loads and slower train speeds compared to heavy rail systems. Here are some key characteristics and features of TR30 steel rail:

1. Umbo: TR30 rail has a specific profile that conforms to industry standards. It is typically characterized by its head width, Urefu, and base width, which determine its load-bearing capacity and compatibility with other rail components.

2. Uzito: TR30 rail typically weighs around 30 kilo kwa mita. Its relatively lighter weight allows for easier handling during installation and maintenance.

3. Vifaa: TR30 rail is commonly made from high-quality steel, ambayo hutoa nguvu nzuri, Durability, na upinzani wa kuvaa na uchovu. The exact specifications of the steel composition may vary depending on regional and industry standards.

4. Usakinishaji: TR30 rail is installed on concrete sleepers or wooden ties using appropriate fastening systems, Kama vile vipande vya vipande au spikes. The rail joints are secured to ensure a seamless track alignment and smooth train operations.

5. Programu tumizi: TR30 rail is specifically designed for light rail transit systems, including urban trams, streetcars, and light metro systems. It is suitable for tracks with lower traffic volumes and lighter trains.

6. Matengenezo: Regular inspection and maintenance are essential for ensuring the safe and efficient operation of TR30 rail tracks. This includes monitoring wear and tear, replacing worn-out sections, and maintaining proper rail alignment.

TR30 steel rail offers several advantages for light rail transit systems. Its lighter weight makes it easier to handle during installation and maintenance activities. The rail’s design and material properties ensure a smooth and comfortable ride for passengers. Hayo, TR30 steel rail is designed to withstand the specific load and speed requirements of light rail transit, making it a reliable choice for urban transportation networks.

It’s worth noting that specific rail standards and specifications may vary between different countries and regions. Basi, it is important to consult local rail authorities or industry guidelines for precise information on TR30 steel rail and its application in specific locations.

Standard EN 13674 - 1:2003 Ina sehemu kuu mbili:

− Mtihani wa kufuzu na vipimo vya kukubalika

Vipimo vya kufuzu ni baadhi ya vipimo vingine ambavyo awali vilifanyika, kama kwa mfano, Kuvunjika kwa ugumu. Vipimo vya kukubalika vinaonyesha mali ya vipimo vilivyoagizwa, ambayo inahakikisha uzalishaji wa reli zenye ubora wa hali ya juu, na mahitaji ya upimaji wa utawala wa reli.

Ubora wa reli unategemea maadili yaliyopimwa ya ugumu, ambayo walianzisha lebo mpya za reli za chuma.

Vipimo vya kufuzu

Upimaji wa sifa lazima ufanyike angalau moja katika miaka mitano na kubwa

Mabadiliko katika teknolojia, Reli za uzalishaji. Mafadhaiko ya ziada ya kupima mabaki yabebwa

nje juu ya aina zote za reli za chuma kila baada ya miaka miwili upeo, ilimradi kwamba longitudo

Kiwango cha shida katika reli kinaweza kufikia hadi 250 MPa.

Mtihani wa kufuzu uliowekwa ni ufuatao:

− kuvunjika kwa ugumu

− Kiwango cha ukuaji wa uchovu

− Upimaji wa uchovu

− Mkazo wa mabaki katika mguu wa reli

− tofauti ya mstari wa katikati

− nguvu ya tensile na elongation

− ubaguzi

− mahitaji mengine ya kufuzu

Vipimo vya kukubalika

Ndani ya upimaji wa kukubalika hufanywa mfululizo wa vipimo vya maabara kama vile:

− muundo wa kemikali (maudhui ya juu ya vipengele vifuatavyo: H, O, Al, V, Elementi za N na oligo)

− microstructure (Kuongezeka kwa X 500)

− shahada ya decarburizing charred layer (inaruhusiwa hadi 0.25 mm)

− usafi wa chuma (Hasa uwepo wa oksidi)

− macrostructure (Mtihani wa Baumann)

− ugumu

− nguvu ya tensile

Reli nyingine za upimaji wa kukubalika ni:

− uvumilivu wa vipimo

− vigezo (template ya kudhibiti)

− Mahitaji ya ukaguzi / uvumilivu kwa ubora wa ndani na ubora wa uso

Hali ya ndani inachunguzwa ultrasound katika udhibiti wa mchakato endelevu, na inajumuisha angalau 70% ya kichwa na angalau 60% Wavuti.

- Kiwango cha UIC 860 V: 1996 - imeagizwa aina nne reli ya chuma ya pearlite katika anuwai ya nguvu ya tensile kutoka 700 kwa 1300 MPa.

- Standard EN 13674 - 2003, hutoa aina saba za ugumu wa chuma cha pearlite katika anuwai 200 kwa 390 HBV, aina ya chuma kulingana na EN 13674, kulingana na maadili ya ugumu (R 200, R 220, R 260, R 260 Mn, 320 Cr, 350 HT, 350 LHT).