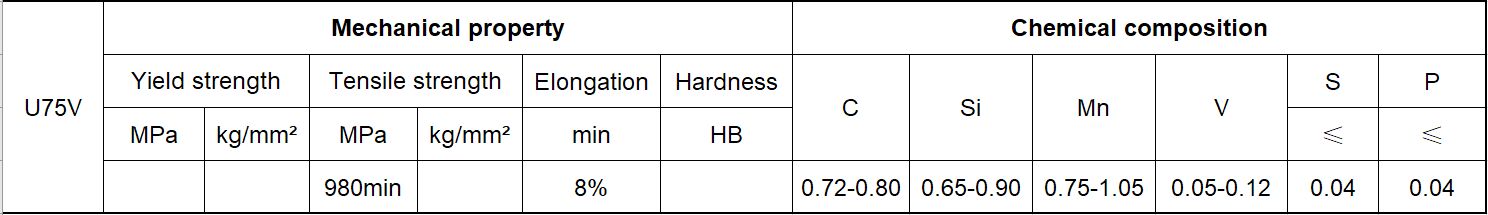

Grooved rail is used for city light railway, characterized by the coexistence of railway tracks and streets, without sleepers and slag. However, for safety reasons, the running speed is generally very slow. So the maximum hardness of this type of steel rail is around 300HB, and the general material is U75V.

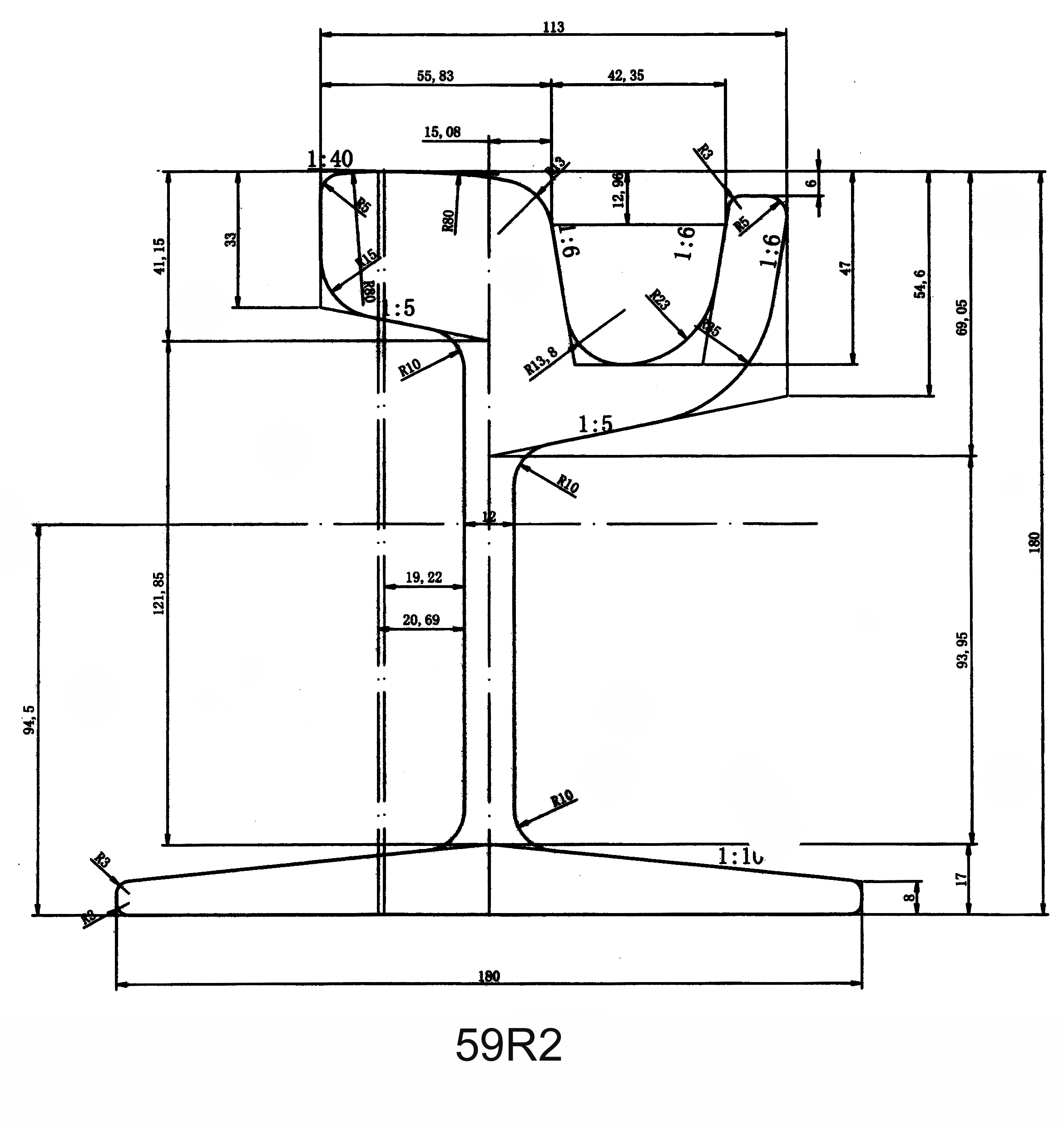

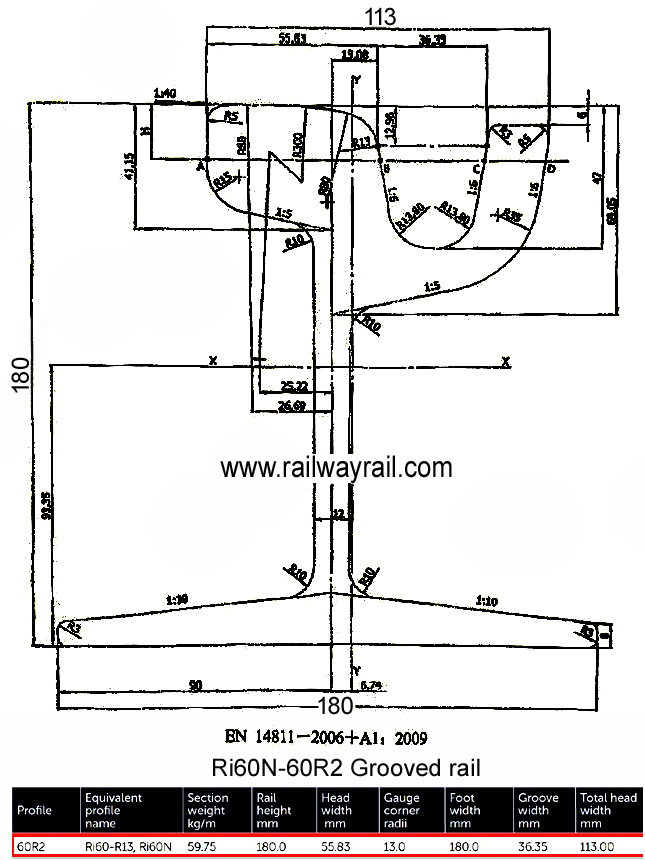

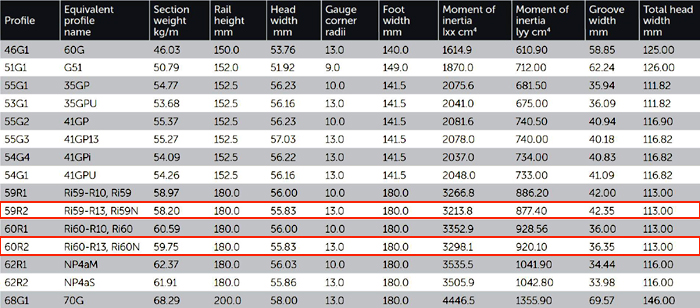

In China only has 59R2 (also be named Ri59-R13, Ri59N) and 60R2 (Ri60-R13, Ri60N), this is new type of 59R1 and 60R1, the gauge corner radii was updated from R10 to R13, can reduce the wear and tear from wheel to rail. The length can be 12m, 12.5m to 25m, if you need special length, please ask us.

Grooved rail is a type of rail commonly used in city light railways. It is unique in that it allows for the coexistence of railway tracks and streets, eliminating the need for sleepers and slag. However, due to safety considerations, the running speed of grooved rail systems is generally kept quite slow. To ensure durability and strength, the maximum hardness of this type of steel rail is typically around 300HB, with the commonly used material being U75V.

In China, there are two main types of grooved rail available: 59R2 (also known as Ri59-R13 or Ri59N) and 60R2 (Ri60-R13 or Ri60N). These rails come in various lengths ranging from 12 meters to 25 metr.

The utilization of grooved rail has several advantages. Firstly, its design allows for the integration of rail lines with existing urban infrastructure, minimizing disruptions to street traffic. This makes it an ideal choice for light rail systems implemented in densely populated cities. Additionally, the absence of sleepers and slag simplifies maintenance work, reducing costs and enhancing operational efficiency.

Although grooved rail offers these benefits, the limited hardness of the steel used necessitates cautious operation at lower speeds. This ensures the safe transportation of passengers while mitigating the wear and tear on the rail system caused by friction with passing vehicles.

It is worth mentioning that developments in rail technology continue to improve the performance of grooved rail systems. Research is ongoing to enhance the hardness and durability of the steel used in these rails, enabling higher running speeds without compromising safety.

In conclusion, grooved rail is a specialized type of rail designed for city light railways where tracks run alongside streets. While safety concerns restrict the running speed, the use of grooved rail provides an efficient and integrated solution for urban transportation. Ongoing advancements in rail technology offer promising prospects for further improving the performance of these systems in the future.

Welcome to ask us the international standard flat bottom rails as below: