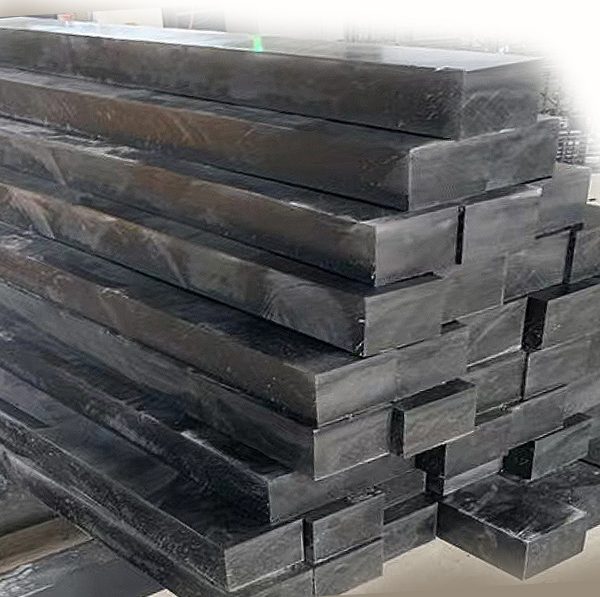

UHMW-PE rail track sleeper

$60.00 $50.00

High density polyethylene plastic sleepers have environmental protection, recyclability, corrosion resistance more than three times higher than wooden sleepers, longer service life, electrical insulation, good weather resistance, good absorption and buffering effect on noise, high crushing strength, strong chemical resistance to liquids or gases, and also can resist ultraviolet rays, termites, moisture and water. Sleeper materials are not affected by temperature and moisture within the range of -40~70 ℃.

- Description

- Inquiry

UHMW-PE rail track sleeper means Ultra High Molecular Weight Polyethylene material rail track sleepers, it is a type of railway sleeper that are made of a high-strength plastic material. Especially in tropical areas, termite erosion can be avoided.

Wooden sleepers damage too quickly under hot and humid conditions, and treated wooden sleepers can last for 5-15 years in Louisiana. Almost all wooden sleepers are treated with creosote for corrosion prevention, which has become an increasingly environmental issue. Moreover, the cost of each wooden sleeper treatment is $5-25 or higher, and the price is steadily increasing.

UHMW-PE rail track sleeper is High density polyethylene plastic sleeper, it has environmental protection, recyclability, corrosion resistance more than three times higher than wooden sleepers, longer service life, electrical insulation, good weather resistance, good absorption and buffering effect on noise, high crushing strength, strong chemical resistance to liquids or gases, and also can resist ultraviolet rays, termites, moisture and water. Sleeper materials are not affected by temperature and moisture within the range of -40~70 ℃.

UHMW-PE rail track sleeper is easier to produce according to the required specifications and make their surfaces rougher than wooden sleepers, thereby reducing the possibility of sliding on the roadbed. Railway consulting experts from Pennsylvania say that PE plastic sleepers have better lateral sliding performance than wooden sleepers. Plastic sleepers can be made longer according to the requirements of track turning and crossing, but it is very difficult to obtain high-quality wood 24 feet long. Another attractive advantage of plastic sleepers is that they are easy to install and can directly use the same equipment and fasteners as wooden sleepers. In addition, to save costs, plastic sleepers and wooden sleepers can also be intermittently used.

UHMW-PE rail track sleeper is known for their durability, impact resistance, and long service life, making them an attractive alternative to traditional timber or concrete sleepers. They are also lightweight, which makes them easier to transport and install.

UHMW-PE rail track sleeper is becoming increasingly popular in railway applications due to their numerous advantages over other materials. They have been proven to provide better track stability, reduce maintenance costs, and improve track longevity. Additionally, they do not rot, crack, or splinter like traditional timber sleepers, and do not corrode like steel sleepers.

Overall, UHMW-PE rail track sleeper offer a superior alternative to traditional sleepers, and are a modern solution for railway construction and maintenance.

We can produce any dimension as your request, such as 150x150x1500mm, 100x150x1500mm, 80x150x1500mm etc. Please contact us the talk the details, we can give you suggestion.