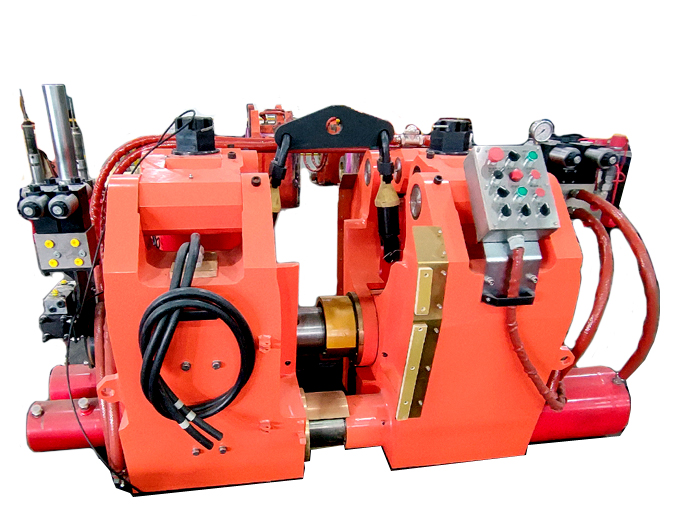

YHG-1200TH movable rail flash welding machine for railway rail welding

$900,000.00 $880,000.00

YHG-1200TH can weld 43, 50, 60, 75kg/m, UIC60, 54E1, 60E1, 136RE, 59R2, 60R2 and other types of rails, as well as high-strength and wear-resistant Bainite materials for heavy haul railways. YHG-1200TH can be used for offline and online welding. The maximum rail height is 180mm, and the maximum slope is 30 ‰.

- Description

- Inquiry

YHG-1200TH movable rail flash welding machine is designed with two 20GP containerized boxes, which can be assembled into a self-propelled rail welding car with an end or middle end. It can complete long unit rail joints and on-site locking welding operations without the need for stretchers.

The maximum weldable sectional area of YHG-1200TH is 12000mm2, which can weld 43, 50, 60, 75kg/m, UIC60, 54E1, 60E1, 136RE, 59R2, 60R2 and other types of rails, as well as high-strength and wear-resistant Bainite materials for heavy haul railways.

YHG-1200TH movable rail flash welding machine can be used for both offline and online welding. The maximum rail height is 180mm, and the maximum slope is 30 ‰.

YHG-1200TH movable rail flash welding machine consists of an operation cabin and a power cabin, which mainly includes a generator set, a noise reduction system, and a tool cabinet. The operation cabin includes: welding machine head, double boom crane, cooling unit, hydraulic pump station, main electric control cabinet, Autotransformer, welding monitoring and printing system (computer, printer and UPS) and various system connections, air conditioner and other auxiliary devices.

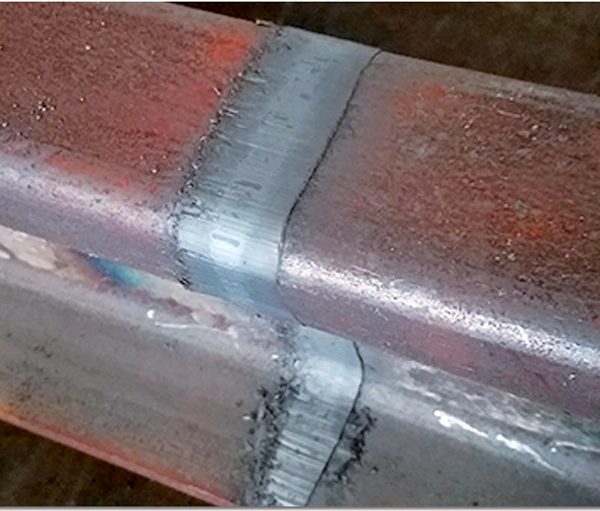

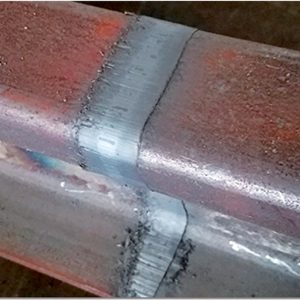

The welding joint quality of YHG-1200TH: Ordinary steel rail welding meets the TB/T1632.1 and TB/T1632.2 standards; Channel shaped steel rails comply with CECS429-2016; It can also meet standards such as European Standard 14587-2-2009, Australian Standard AS1085.20-2012, and American Standard AREMA MRE Chapter 4-2017.

The options for YHG-1200TH include:

① New energy system power supply (high-power energy storage power supply system). The energy storage power supply system mainly consists of: energy storage battery pack, Battery management system (BMS), energy storage inverter (PCS), transformer, air conditioning system, smoke sensor and other environmental monitoring equipment, battery cabinet, combiner cabinet, output stabilization cabinet, fire protection system and cabin. After a full charge, about 50-60 connectors can be welded. The battery pack has a cycle life of 3500 times (average usage of 15 years). Output voltage 400AC, output rated power 630kw;

② Tail gas purification treatment meets the emission standards for particulate matter specified in the national standard “Comprehensive Emission Standard for Air Pollutants” GB16297: more than 95% of carbon smoke and particulate matter (Pm) are treated, the smoke blackness reaches Lingermann level 1, the particulate emissions are less than 50mg/M3, and the smoke blackness opacity is less than 15%;

③ Flat hydraulic lifting device, equipped with 4 sets of hydraulic leg oil cylinders;

④ Real time or historical data can be viewed through mobile apps and web pages, and the status of welding machine components, welding data, and curves can be monitored in real time.

Main specifications and characteristics of YHG-1200TH movable rail flash welding machine

(1) Containers have functions such as wind, sand, ventilation, insulation, and UV radiation protection, and can adapt to different environments and types (such as urban rail, subway, etc.).

(2) It has the function of automatically aligning the steel rails to be welded.

(3) It has the function of completing the alignment of joints in one go, starting welding, and removing welding burrs.

(4) Capable of butt welding 1500m~2000m unit rail joints and rails.

(5) YHG-1200TH movable rail flash welding machine has reliable pressure maintaining and tumor pushing function.

(6) Continuous and pulsating flash welding can be used for welding.

(7) Take reliable fire prevention measures for various pipelines and cables near the welding machine head; And it should be firmly tied and tightly attached to the body to ensure that it does not affect the operation limit; To meet the needs of narrow welding operation space such as tunnels, dual side operation panels are set up, which can be operated separately on both sides.

(8) The welding management system can automatically monitor the entire welding process, supervise, record, and analyze the welding data of each welding head, and automatically judge the welding results based on predetermined standards.

(9) YHG-1200TH can display and record welding data such as voltage, current, displacement, pressure and time changes in real-time (and draw them into graphics). Once generated, welding data cannot be edited. Can manually input welding auxiliary parameters such as line type, up and down, station interval, mileage, left and right strands, steel rail manufacturer model, steel rail length, welding personnel, welding date, etc. Auxiliary parameters can be modified with permission. Can provide detailed and complete welding data for each stage for diagnostic analysis, and can provide welding energy data for each stage.

(10) It is possible to print stage welding reports (daily reports, monthly reports, etc.). The content includes the model, steel grade, welding date, welding time, welding joint identification code, flash speed, accelerated final speed, top forging amount, rail consumption, short circuit impedance, clamping condition, whether the welding joint is qualified, as well as line type, line type, mileage mark, mileage, left and right strands, station section information, etc.

(11) Equipped with a reliable cooling system, ensuring continuous operation for 8 hours.

(12) The hydraulic oil adopts a water cooling method, which can closed-loop control the oil temperature range and display the hydraulic oil temperature.

(13) Equipped with an internal lighting system for easy maintenance.

(14) Production efficiency: Pulse flash welding with no less than 16 welding heads per hour; Continuous flash welding shall not be less than 12 welding heads per hour.