Bar colector de oțel pentru instalația de topire din aluminiu

$720.00 $600.00

Bara inovatoare de colectare catodică ar trebui să fie din oțel cu conținut foarte scăzut de carbon, este ASTM Grad 1006 oțel cu conținut scăzut de carbon, deoarece oțelul cu conținut scăzut de carbon are o electroconductibilitate bună. În mod normal, conținutul de carbon ar trebui să fie mai mic decât 0.06%, materialul numit SAE 1006, componentele chimice de mai jos:

Carbon ≤0,06%, Siliciu ≤0,07%, Mangan ≤0,45%, Fosfor ≤03%, Sulf ≤0,04%, Azot ≤0,012%.

- Descriere

- Detalii rapide

- Ambalare & Livrare

- Anchetă

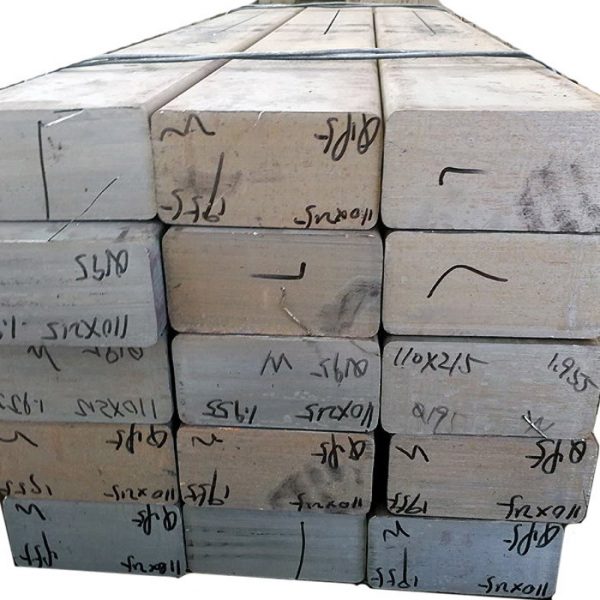

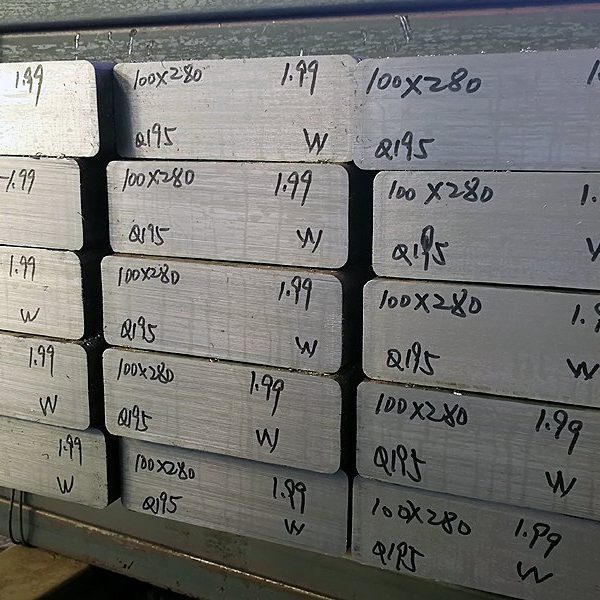

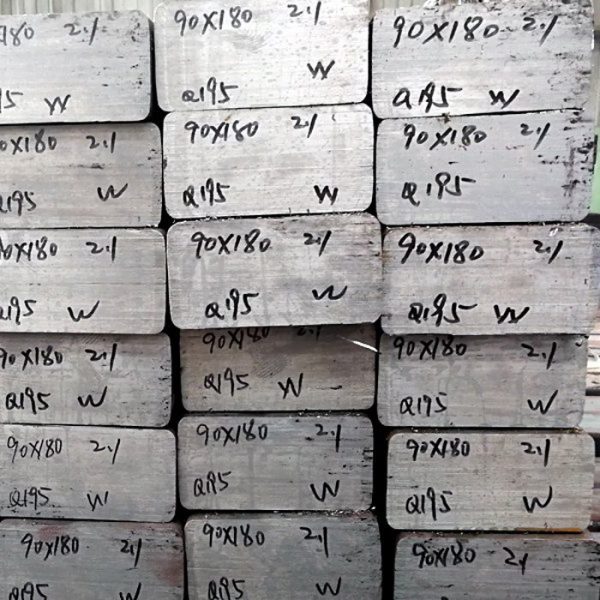

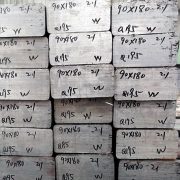

SAE 1006 Cathode plate for Aluminum melting, oțelul cu conținut scăzut de carbon are o conductivitate electrică bună. Our product is produced in big steel factory, the quality is very good, we can supply any size products as your requirement, please contact us to talk about the details.

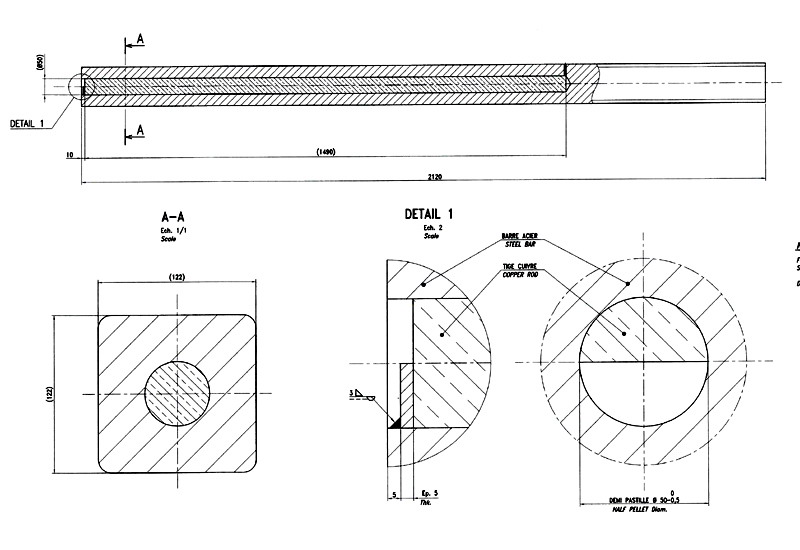

Barele colectoare din oțel au o secțiune transversală pătrată cu inserție rotundă de cupru. The quality of steel and copper insert, their dimensions and its fitting in the finished collector bar should be as below and in accordance with the drawing:

- Physical:

- Steel collector bar tolerance:

Lungime (milimetru) 0 / +10

Lățime (milimetru) -2~+2

Înălțime (milimetru) -2~+2

- Steel collector bar geometrical tolerances

- Angle defect at cut end less than 5 milimetru

- Flatness at cut ends less than 2 milimetru

- Angle defect of cross-section less than 3 milimetru

- Deflection on the whole bar less than 3 milimetru

(Laterally and Vertically)

- Local deflection less than 3 mm per meter

(Laterally and Vertically)

- Flatness less than 3 milimetru

(Transversally and vertically)

- Twist less than 3 mm per meter

- Round off 4-15 milimetru

- Steel collector bar surface condition

- Lateral surfaces: Free or metal pickup and cracks deeper than 3 milimetru

- Surface roughness not projecting by more than 1 milimetru

- Cut by saw (Cutting with shears or oxyacetylene torch are prohibited unless followed by grinding). Cuts must not present manufacturing defects (Necessitating a supplementary grinding).

- No painting on the bar ends.

- Physicochemical characteristics

- Composition of collector bar steel (Gravimetrical analysis)

The cathode bar application requires a ferrous metal with a relatively low electrical resistivity and a good weldability (De exemplu 1020 Grade or ASTM A29/A29 M-99) and following composition requirement:

Carbon: ≤0.06%

Silicon: ≤0.07%

Manganese: ≤0.45%

Phosphorus: ≤0.03%

Sulphur: ≤0.04%

Azot ≤0,012%.

The steel supplier must supply to the client its proposal with typical steel composition range expected for the following chemical elements: Al, C, Cr, Cu, Si, Mn, Ni, S, P & N

- Cathode bar inspection

Acceptance of cathode bars takes place in the supplier’s premises and includes:

- A check of the quality control results of the supplier, and especially a check of the analysis certificates guaranteeing that the quality of the bar steel meets the requirements of the specification

- A check of bar dimensions are aspect.

As regards inspection procedures, the word “LOT” means “LOT of material to be inspected”, i.e. All the cathode bars, out of which a sample will be taken to check for compliance with the acceptance criteria.

The cathode bards in a given LOT must be manufactured according to the same process and with the same quality of steel.

NB: When there is no acceptance on site, all the supplier control results must be sent to the lient purchasing department before shipping for acceptance.

- Clasă:

-

SAE 1006/Q195 Cathode plate for Aluminum melting

- Grosime:

-

50-150milimetru

- Lățime:

-

50mm-300mm

- Lungime:

-

1000~3000mm

- Locul de origine:

-

Mongolia Interioară, China (Continent)

- Nume de marcă:

-

Baosteel

- Numărul modelului:

-

SAE 1006/Q195

- Aplicație:

-

Electrolytic aluminium factory Cathode bar

- Tehnică:

-

Laminate la cald

- Utilizare specială:

-

Oțel turnat

- Nume produs:

-

Cathode plate for Aluminum melting

- Tip:

-

Orice dimensiune necesară

- Formă:

-

Bar pătrat

- Material:

-

SAE 1006/Q195

- Tehnologie:

-

Laminate la cald

- Condiții de livrare:

-

Fante

- Suprafață:

-

Câmpie

- Tratarea suprafețelor:

-

Unghi curbat

- Certificat:

-

Certificat de calitate

- Nume:

-

SAE 1006/Q195 - Cathode plate for Aluminum melting

- Detalii ambalaj

- În pachet pot fi încărcate cu stivuitorul

- Timp de livrare

- 30 Zile

- Capacitatea de aprovizionare:

- 5000 Ton / tone pe zi

- Port:

- Portul Tianjin

Produse conexe

-

Citeste mai multVizualizare rapidă

Citeste mai multVizualizare rapidăBara plată a șinei Q345B

$600.00Bara plană feroviară este utilizată pentru o mulțime de structură, putem produce orice material și dimensiune ca cererea dvs., de asemenea, poate produce o suprafață netedă bară plană, dimensiunea de mai jos:

10x30x6000mm Q235 bar plat

20x35x6000mm Q235 bar plat

30x40x6000mm Q234 bar plat

(10-30)x(30-120)x6000mm Q235/Q345 bar plat

40x40x6000mm ST52 șină bară plată

60x40x6000mm ST52 șină bară plată

70x40x6000mm ST52 șină bară plată

80x40x6000mm ST52 șină bară plată

-

Citeste mai multVizualizare rapidă

Citeste mai multVizualizare rapidăBara de oțel catodică pentru topirea aluminiului

SAE 1006/Q195 Materiale catodice pentru topirea aluminiului, oțelul cu conținut scăzut de carbon are o conductivitate electrică bună. Pentru a produce bara de colectare catodică din aluminiu electrolitic este un proces strict, deoarece sistemul de electrowinning este curent continuu greu, electroconductivitatea va decide costul aluminiului, deci trebuie sa aiba electroconductivitate foarte buna, pentru a economisi consumul de energie și pentru a crește eficiența electrolitică.

$720.00$600.00 -

Citeste mai multVizualizare rapidă

Citeste mai multVizualizare rapidăTijă rotundă de oțel

Detalii rapide- Material: Q235 tijă de oțel / 40Mn oțel rotund

- Dimensiuni: Diametru:16mm-250mm

- Locul de origine: Mongolia Interioară, China (Continent)

- Aplicație: Sistem de rulmenți

- Formă: Rotund Bar

- Numărul modelului: OD: 40-150milimetru

- Nume de marcă: Oțel Bao

- Standard: GB

- Nume produs: Oțel rotund

- Tehnica de fabricație: laminate la cald

- Otel: Q235/20#/40Mn

- Pachet: În balot

$800.00$720.00 -

Citeste mai multVizualizare rapidă

Citeste mai multVizualizare rapidăSWRH82B țagle de oțel aparțin oțelului cu conținut ridicat de carbon

Putem furniza orice fel de țagle de oțel în cantitate mare cu preț competitiv, în special oțel special, de exemplu: SWRH82B, SWRH62A/72A sau SWRM8.

Dimensiune: 11m × 152mm × 152mm.

Dacă aveți nevoie, Vă rugăm să ne lăsați un mesaj.

-

Citeste mai multVizualizare rapidă

Citeste mai multVizualizare rapidăBara colector catodică

SAE 1006 bara catodică ar trebui să fie din oțel cu conținut foarte scăzut de carbon, deoarece oțelul cu conținut scăzut de carbon are o electroconductibilitate bună. În mod normal, conținutul de carbon ar trebui să fie mai mic decât 0.06%, materialul numit SAE 1006

$720.00$600.00 -

Citeste mai multVizualizare rapidă

Citeste mai multVizualizare rapidăSWRH72A țaglă de oțel pentru sârmă din oțel cu conținut ridicat de carbon

Putem furniza orice fel de țagle de oțel în cantitate mare cu preț competitiv, în special oțel special, de exemplu: SWRH82B, SWRH72A sau SWRM8.

Dimensiune: 11m × 152mm × 152mm.

Dacă aveți nevoie, Vă rugăm să ne lăsați un mesaj.

-

Citeste mai multVizualizare rapidă

Citeste mai multVizualizare rapidăBară unghiulară pentru fabricarea turnurilor de transmisie sau construcția navală maritimă

O bară unghiulară, cunoscut și sub numele de L-bar sau fier unghiular, este o componentă structurală din oțel utilizată în mod obișnuit în construcția turnurilor de transmisie și a construcțiilor navale maritime.

În construcția turnurilor de transmisie, Barele unghiulare sunt utilizate ca elemente structurale importante pentru a oferi stabilitate și suport. Ele sunt adesea folosite ca bretele, brațe încrucișate, și elemente diagonale pentru a rezista diferitelor sarcini și forțe pe care turnul le poate experimenta, cum ar fi vântul, gheață, și greutatea liniilor de transport. Barele unghiulare sunt alese pentru rezistența lor, versatilitate, și rentabilitatea în aceste aplicații.

În construcția navală maritimă, Barele unghiulare sunt, de asemenea, utilizate pe scară largă. Ele sunt utilizate pentru diverse aplicații, cum ar fi încadrarea, Rigidizare, și structuri de sprijin. Barele unghiulare asigură integritatea structurală și stabilitatea corpului navei și suprastructurii. Ele sunt utilizate în construcția pereților etanși, Cadre, Punţi, și alte componente critice. Barele unghiulare sunt preferate în construcția navală datorită raportului ridicat rezistență-greutate, ușurința de fabricație, și rentabilitate.$650.00$560.00 -

Citeste mai multVizualizare rapidă

Citeste mai multVizualizare rapidăQ345 bară plată cu șină trasă la rece

$600.00Bara plană feroviară este utilizată pentru o mulțime de structură, putem produce orice material și dimensiune ca cererea dvs., de asemenea, poate produce o suprafață netedă bară plană, dimensiunea de mai jos:

10x30x6000mm Q235 bar plat

20x35x6000mm Q235 bar plat

30x40x6000mm Q234 bar plat

(10-30)x(30-120)x6000mm Q235/Q345 bar plat

40x40x6000mm ST52 șină bară plată

60x40x6000mm ST52 șină bară plată

70x40x6000mm ST52 șină bară plată

80x40x6000mm ST52 șină bară plată

-

Citeste mai multVizualizare rapidă

Citeste mai multVizualizare rapidăȚagla de oțel SWRM8 aparține oțelului cu conținut scăzut de carbon

Putem furniza orice fel de țagle de oțel în cantitate mare cu preț competitiv, în special oțel special, de exemplu: SWRH82B, SWRH62A/72A sau SWRM8.

Dimensiune: 11m × 152mm × 152mm.

Dacă aveți nevoie, Vă rugăm să ne lăsați un mesaj.

-

Citeste mai multVizualizare rapidă

Citeste mai multVizualizare rapidăTablă de oțel moale pentru construcții navale

Standard: CSC

Clasă: 2C, 3C, 4C, 5C, 12MNC, 16MNC, 15MnTiC, 14MnVtirec

Locul de origine: Liaoning, China

Nume de marcă: Yueqi

Numărul modelului: A B D E AH32 AH36 DH32 DH36 EH32 EH36

Tip: Placă de oțel, Placă cu conținut scăzut de aliaj

Tehnică: Laminate la cald

Tratamentul suprafețelor: Sablare și Primer

Aplicație: Placă de expediere

Utilizare specială: Placă de oțel de înaltă rezistență

Lățime: 2000mm-2500mm

Lungime: 6000mm-12000mm

Toleranță: ±2%

Serviciul de procesare: Aplecare, Sudură, Tăiere, Bătaie

Timp de livrare: 45 Zile

Nume produs: Placă de oțel marină

Calitate normală a oțelului material: Ușoară oțel ABS GR. A B D E

Material normal: 2C, 3C, 4C & 5C

Grad de oțel material de înaltă rezistență: AH32 AH36 DH32 DH36 EH32 EH36

Material de înaltă rezistență: Oțel slab aliat 12MnC, 16MnC, 15MnTiC, 14MnVTiReC

Obicei: utilizate pentru construcția de nave și fabricarea structurii corpului navei

MOQ: 300 Tone

Avantaj: Preț competitiv și calitate bună

Margine: 4 tăiere

Certificat: Certificate materiale de certificare de clasă

Capacitatea de aprovizionare: 3000 Ton / tone pe zi

Ambalaj & Livrare

Detalii ambalaj: Pachet în container sau mărfuri în vrac

Port: Portul Tianjin

Timp de pregătire: A se negocia$1,300.00$1,100.00