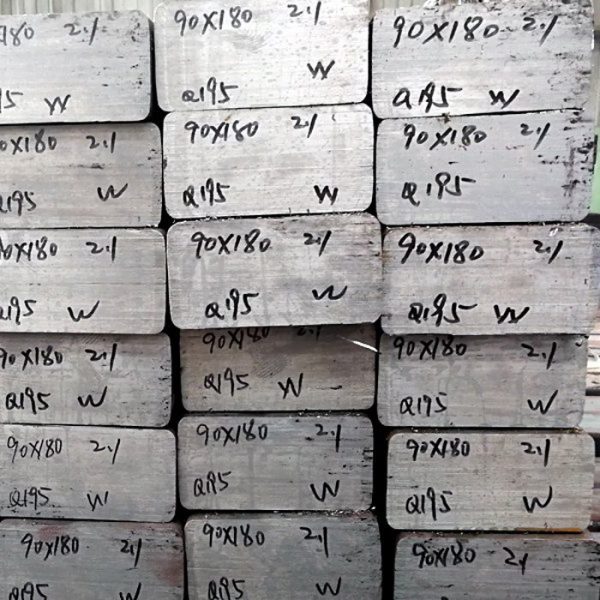

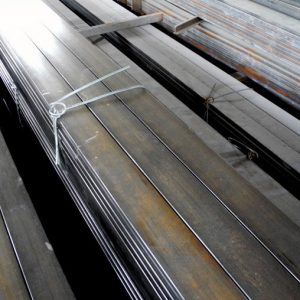

SAE1006 low carbon steel bar for Aluminum electrowinning

$720.00 $600.00

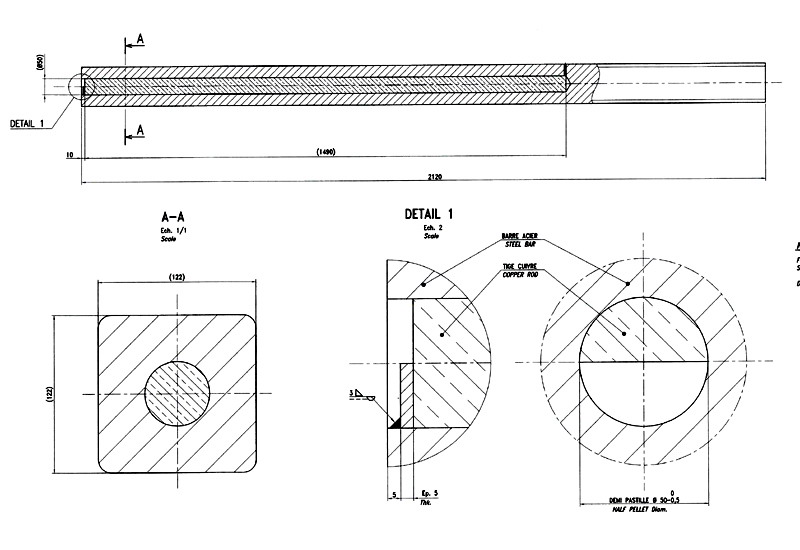

SAE 1006/Q195 Aluminum melting cathode electrowinning is used for electrolytic aluminium factory, the low carbon steel has good electrical conductivity. To produce cathode collector bar of electrolytic aluminum is a strict process, because the electrowinning system is heavy DC current, the electroconductivity will decide the cost of Aluminum, so it must have very good electroconductivity, to save power consumption and raise the electrolytic efficiency.

- Description

- Quick Details

- Packaging & Delivery

- Inquiry

SAE1006 low carbon steel bar for Aluminum electrowinning is used for electrolytic aluminium factory, the low carbon steel has good electrical conductivity.

SAE1006 low carbon steel bar for Aluminum electrowinning

SAE1006 low carbon steel bar for Aluminum electrowinning are commonly used as anode material in the aluminum electrowinning process. Electrowinning is a method of extracting metals from their ores or salts by passing an electric current through a solution containing the metal ions.

In the aluminum electrowinning process, SAE1006 low carbon steel bars are used as the positive electrode, also known as the anode. The aluminum ions in the solution are attracted to the negatively charged cathode, where they are reduced to metallic aluminum and deposited on its surface.

SAE1006 low carbon steel bar for Aluminum electrowinning must be able to withstand the harsh chemical environment of the electrowinning process while providing efficient electrical conductivity. They are typically manufactured with a specialized coating that helps to prevent corrosion and improve their lifespan.

To ensure optimal performance, SAE1006 low carbon steel bars must be carefully selected based on factors such as their composition, size, and shape. They should also be regularly inspected and replaced as needed to maintain the efficiency and safety of the electrowinning process.

In addition to their use in aluminum electrowinning, SAE1006 low carbon steel bars may also be used in other applications where high electrical conductivity and resistance to corrosion are required, such as in the production of other non-ferrous metals.

Overall, SAE1006 low carbon steel bar for Aluminum electrowinning play a critical role in the aluminum electrowinning process, providing reliable and efficient electrical conductivity while withstanding the extreme conditions of the electrolytic cell. As a supplier of steel products for industrial applications, we offer a range of high-quality SAE1006 low carbon steel bars and related components to meet the needs of our customers in the aluminum industry and beyond. If you require more information or would like to request a quote, please do not hesitate to contact us.

- Grade:

-

SAE 1006/Q195

- Thickness:

-

50-150mm

- Width:

-

50mm-300mm

- Length:

-

1000~3000mm

- Place of Origin:

-

Inner Mongolia, China (Mainland)

- Brand Name:

-

Baosteel

- Model Number:

-

SAE 1006/Q195

- Application:

-

Electrolytic aluminium factory Cathode bar

- Technique:

-

Hot Rolled

- Special Use:

-

Mold Steel

- Product Name:

-

Aluminum melting cathode electrowinning

- Type:

-

Any required size

- Shape:

-

Square Bar

- Material:

-

SAE 1006/Q195

- Technology:

-

Hot rolled

- Delivery Condition:

-

Slotted

- Surface:

-

Plain

- Surface treatment:

-

Curved angle

- Certificate:

-

Quality certificate

- Name:

-

SAE 1006 - Aluminum melting cathode electrowinning

Reference documents:

ASTM A572 Gr 50 Hot rolled products of non-alloy structural steels – Technical delivery conditions

ASTM A36/A36M-14 Standard specification for Carbon structural steel

ASTM A1018/A1018M-16a Standard specification for steel, sheet and strip, heavy-thickness coils, Hot-rolled, Carbon, Commercial, Drawing, Structural, High-strength Low-alloy, High-strength Low-alloy with improved formability, and Ultra-high strength

- Packaging Details

- In bundle can be loaded by forklift

- Delivery Time

- 30 days

- Supply Ability:

- 5000 Ton/Tons per Day

- Port:

- Tianjin port

Related Products

-

Read MoreQuick View

Read MoreQuick ViewCathode collector bar

SAE 1006 cathode bar should be very low carbon steel, because low carbon steel has good electroconductibility. Normally the content of carbon should less than 0.06%, the material named SAE 1006

$720.00$600.00 -

Read MoreQuick View

Read MoreQuick ViewAngle bar for transmission tower making or marine shipbuilding

An angle bar, also known as an L-bar or angle iron, is a commonly used structural steel component in the construction of transmission towers and marine shipbuilding.

In the construction of transmission towers, angle bars are used as important structural members to provide stability and support. They are often used as braces, cross arms, and diagonal members to withstand the various loads and forces that the tower may experience, such as wind, ice, and the weight of transmission lines. Angle bars are chosen for their strength, versatility, and cost-effectiveness in these applications.

In marine shipbuilding, angle bars are also widely utilized. They are used for various applications such as framing, stiffening, and supporting structures. Angle bars provide structural integrity and stability to the ship’s hull and superstructure. They are used in the construction of bulkheads, frames, decks, and other critical components. Angle bars are preferred in shipbuilding due to their high strength-to-weight ratio, ease of fabrication, and cost-effectiveness.$650.00$560.00 -

Read MoreQuick View

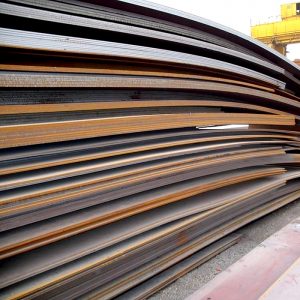

Read MoreQuick ViewShipbuilding mild steel plate

Standard: CCS

Grade: 2C, 3C, 4C, 5C, 12MNC, 16MNC, 15MnTiC, 14MnVtirec

Place of Origin: Liaoning, China

Brand Name: Yueqi

Model Number: A B D E AH32 AH36 DH32 DH36 EH32 EH36

Type: Steel Plate, Low-Alloy Plate

Technique: Hot Rolled

Surface Treatment: Sand blasting and Primer

Application: Ship Plate

Special Use: High-strength Steel Plate

Width: 2000mm-2500mm

Length: 6000mm-12000mm

Tolerance: ±2%

Processing Service: Bending, Welding, Cutting, Punching

Delivery Time: 45 days

Product Name: Marine steel plate

Normal Material steel grade: Mild Steel ABS GR.A B D E

Normal material: 2C, 3C, 4C & 5C

Hi strength material steel grade: AH32 AH36 DH32 DH36 EH32 EH36

Hi strength material: Low alloy steel 12MnC, 16MnC, 15MnTiC, 14MnVTiReC

Usage: used for shipbuilding and the manufacture of ship’s hull structure

MOQ: 300 tons

Advantage: Competitive price and good quality

Edge: 4 cutting

Certificate: Class certification material certificates

Supply Ability: 3000 Ton/Tons per Day

Packaging & Delivery

Packaging Details: Bundle in container or bulk cargo

Port: Tianjin port

Lead Time: To be negotiated$1,300.00$1,100.00 -

Read MoreQuick View

Read MoreQuick ViewQ345B rail flat bar

$600.00Rail flat bar is used for a lot of structure, we can produce any material and size as your request, also can produce smooth surface flat bar, the size as below:

10x30x6000mm Q235 flat bar

20x35x6000mm Q235 flat bar

30x40x6000mm Q234 flat bar

(10-30)x(30-120)x6000mm Q235/Q345 flat bar

40x40x6000mm ST52 rail flat bar

60x40x6000mm ST52 rail flat bar

70x40x6000mm ST52 rail flat bar

80x40x6000mm ST52 rail flat bar

-

Read MoreQuick View

Read MoreQuick ViewSWRH72A steel billet for high carbon steel wire rod

We can supply any kind of steel billets in large quantity with competitive price, especially special steel, such as: SWRH82B, SWRH72A or SWRM8.

Dimension: 11m × 152mm × 152mm.

If you need it, please leave message to us.

-

Read MoreQuick View

Read MoreQuick ViewQ345 cold drawn rail flat bar

$600.00Rail flat bar is used for a lot of structure, we can produce any material and size as your request, also can produce smooth surface flat bar, the size as below:

10x30x6000mm Q235 flat bar

20x35x6000mm Q235 flat bar

30x40x6000mm Q234 flat bar

(10-30)x(30-120)x6000mm Q235/Q345 flat bar

40x40x6000mm ST52 rail flat bar

60x40x6000mm ST52 rail flat bar

70x40x6000mm ST52 rail flat bar

80x40x6000mm ST52 rail flat bar

-

Read MoreQuick View

Read MoreQuick ViewRound steel rod

Quick Details- Material: Q235 steel rod/40Mn round steel

- Dimensions: Diameter:16mm-250mm

- Place of Origin: Inner Mongolia, China (Mainland)

- Application: Bearing System

- Shape: Round Bar

- Model Number: OD: 40-150mm

- Brand Name: Bao steel

- Standard: GB

- Product Name: Round steel

- Manufacturing technique: hot rolled

- Steel grade: Q235/20#/40Mn

- Package: In bale

$800.00$720.00 -

Read MoreQuick View

Read MoreQuick ViewSWRH82B steel billet belong to high carbon steel

We can supply any kind of steel billets in large quantity with competitive price, especially special steel, such as: SWRH82B, SWRH62A/72A or SWRM8.

Dimension: 11m × 152mm × 152mm.

If you need it, please leave message to us.

-

Read MoreQuick View

Read MoreQuick ViewCathode collector bar for Aluminum melting plant

SAE 1006 Cathode collector bar is used for electrolytic aluminium factory, the low carbon steel has good electrical conductivity. To produce cathode collector bar of electrolytic aluminum is a strict process, because the electrowinning system is heavy DC current, the electroconductivity will decide the cost of Aluminum, so it must have very good electroconductivity, to save power consumption and raise the electrolytic efficiency.

$720.00$600.00 -

Read MoreQuick View

Read MoreQuick ViewQ195 Cathode flat steel

Q195 cathode flat steel is used for electrolytic aluminium factory, the low carbon steel has good electrical conductivity. To produce cathode collector bar of electrolytic aluminum is a strict process, because the electrowinning system is heavy DC current, the electroconductivity will decide the cost of Aluminum, so it must have very good electroconductivity, to save power consumption and raise the electrolytic efficiency.

$720.00$600.00