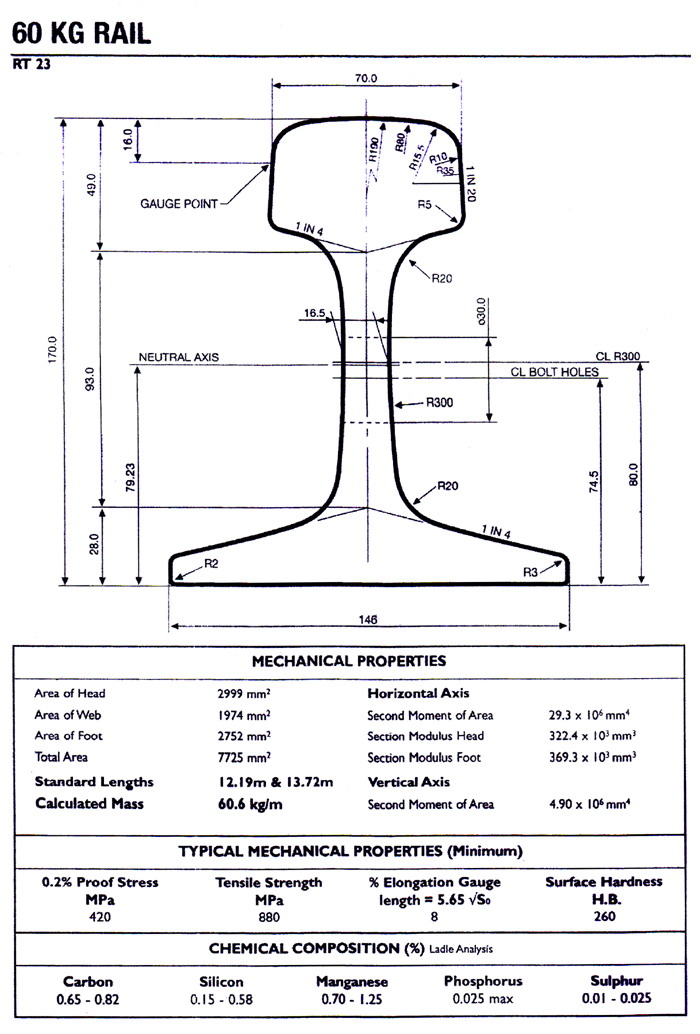

O trilho de aço padrão australiano de 60kg/m é normalmente usado em aplicações ferroviárias pesadas, tais como linhas férreas principais e de transporte ferroviário de mercadorias. O trilho tem uma largura de cabeça de 70mm, uma altura da cabeça de 49mm, uma largura do pé de 146mm, e pé de 28mm. Este tipo de trilho é projetado para suportar cargas pesadas e altas velocidades e é comumente usado na rede ferroviária da Austrália.

As dimensões corretas para o trilho de aço padrão australiano de 60kg/m são as seguintes:

– Largura da cabeça: 70milímetro

– Altura da cabeça: 49milímetro

– Foot Width: 146milímetro

– Foot Height: 28milímetro

– Overall Length: 16.5m

The rail weighs 60kg per meter and is commonly used in heavy rail applications in Australia for both passenger and freight services.

COMO 1085.1-2002 60 kg rail is a specific category of rail that conforms to this standard. It refers to a type of rail that weighs 60 kilograms per meter and meets the requirements for flash butt welding as defined in AS 1085.1-2002. This type of rail is commonly used in railway construction and maintenance in Australia.

AS60 rail is a type of steel rail commonly used for railway track construction. Tem um comprimento padrão de 25 meters and a weight of around 60 quilogramas por metro. The AS60 rail is mainly used for heavy-haul railway lines that are designed to carry high loads over long distances. Its usage is well-suited to heavy-duty freight transport and is capable of handling heavy locomotives and large cargo loads.

The installation of AS60 rail typically involves several steps, including the following:

1. Site preparation: The first step is to prepare the site for railway track construction. This involves clearing the land, leveling the ground, and laying a foundation of ballast.

2. Alinhamento: The AS60 rails should be aligned correctly and positioned according to the design specifications. This step also includes ensuring that the rails are evenly spaced and straight.

3. Rail fastening: The rails should be firmly fastened to the sleepers or ties using clips or other fastening methods. This ensures that the rails remain in place over time and maintain their correct position.

4. Soldagem: Se necessário, welding is done to join the rails together. This step is important to ensure that there are no gaps or misalignments between the rails, which would cause problems for trains traveling over them.

5. Finishing touches: Once the rails are secured in place, the final touches are added, such as adding ballast between the sleepers to hold the rails firmly in place and providing drainage to prevent water from accumulating.

As installation of railway tracks can be complex and requires specialized knowledge and tools, it is often best carried out by experienced professionals in rail construction.

Transporting an AS60 rail can be a complex task due to its size and weight. Here are some general steps for transporting an AS60 rail:

1. Obtain the necessary permits and permissions to transport the rail. This may involve obtaining permits from local authorities, obtaining clearance from utility companies, and obtaining special permits for oversized loads.

2. Choose a suitable mode of transportation. Depending on the distance, terrain, and infrastructure, the rail can be transported by truck, train, or barge.

3. Prepare the rail for transportation. This may involve cutting the rail into shorter sections, bundling the sections together, and securing them to a flatbed trailer or railcar.

4. Load the rail onto the selected transportation vehicle using heavy equipment such as a crane.

5. Secure the rail to prevent it from shifting during transport.

6. Transport the rail to its destination, following all safety regulations and traffic laws.

7. Unload the rail using appropriate heavy equipment and place it in its final location.

Please note that transporting an AS60 rail can be a specialized task that requires careful planning and execution. It may be helpful to consult with a transportation expert or railway specialist to ensure that the rail is transported safely and efficiently.

Nós podemos fornecer os trilhos de fundo plano padrão internacional como abaixo, se você precisar, por favor, sinta-se livre para nos perguntar: