The Brazil hump type locomotive track reducer is used to reduce the running speed of locomotives and is a key component in the railway industry, playing an important role in the efficient operation of hump yards. Hump shunting yard is an important component of railway freight operation, where trains are sorted and classified to be allocated to different destinations. The locomotive track reducer ensures smooth operation of the train on the hump, achieving safe and efficient sorting of track vehicles.

Brazil Hump type locomotive track reducer

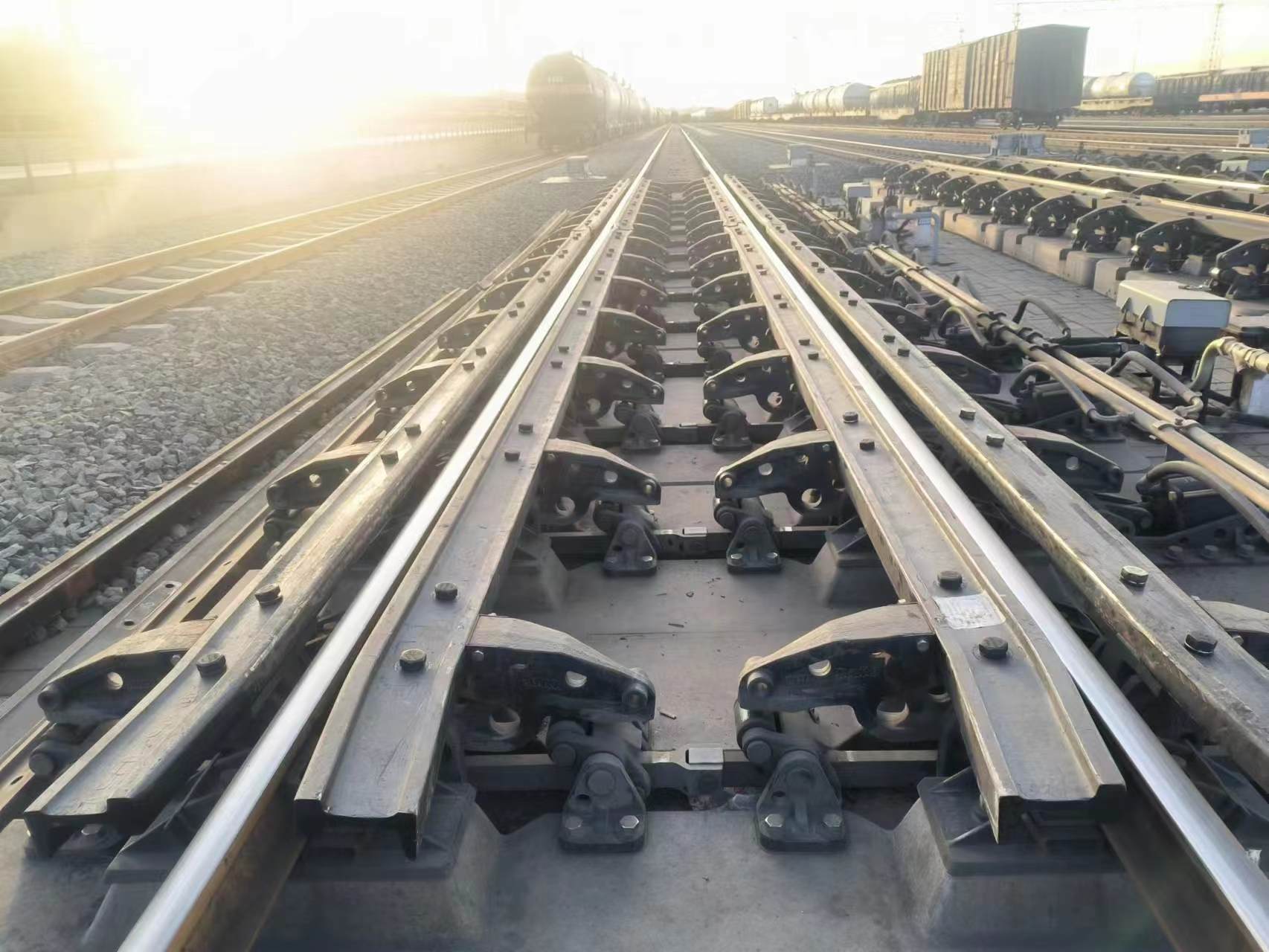

The Brazil Hump type locomotive track reducer is specifically designed to handle heavy loads and provide precise control over train movement. It consists of a series of track sections that are inclined to create a downhill slope, allowing gravity to assist in slowing down and sorting the rail cars. The reducer uses a combination of mechanical and hydraulic systems to control the speed and direction of the trains.

One of the key features of the Brazil Hump type locomotive track reducer is its robust construction. It is built to withstand the enormous forces exerted by the moving trains, ensuring long-term reliability and durability. The track sections are made from high-quality steel, capable of accommodating heavy loads without deformation or damage. Suplimentar, the hydraulic systems are designed to operate under high pressures, providing precise control over train movement.

The Brazil Hump type locomotive track reducer also incorporates advanced safety features to protect both the equipment and personnel. The system is equipped with sensors and detectors that monitor various parameters such as train speed, position, and weight. This information is used to automatically adjust the hydraulic systems and control the train’s movement, ensuring safe and efficient sorting operations.

Mai mult decât atât,, the Brazil Hump type locomotive track reducer is designed for ease of maintenance. It incorporates accessible components and modular design, allowing for quick and straightforward repairs or replacements. The system also includes comprehensive diagnostic tools and self-monitoring capabilities, enabling proactive maintenance and minimizing downtime.

The Brazil Hump type locomotive track reducer has gained global recognition for its outstanding performance and reliability. It has been successfully implemented in hump yards worldwide, contributing to improved efficiency and productivity in rail freight operations. The reducer’s ability to handle heavy loads, precise control over train movement, and advanced safety features make it an essential component in modern railway systems.

În concluzie,, the Brazil Hump type locomotive track reducer is a critical component in hump yards, ensuring the safe and efficient sorting of rail cars. Construcția sa robustă, advanced safety features, and ease of maintenance make it a preferred choice for railway operators worldwide. The reducer’s contribution to the improvement of rail freight operations cannot be overstated, making it an integral part of the global railway industry.

Putem furniza șinele standard internaționale cu fund plat ca mai jos:

Dacă ai nevoie de cineva, Vă rugăm să nu ezitați să ne contactați.