90Rel RA

$850.00 $800.00

Standar: AREMA, ASTM

Derajat: 900A/1100

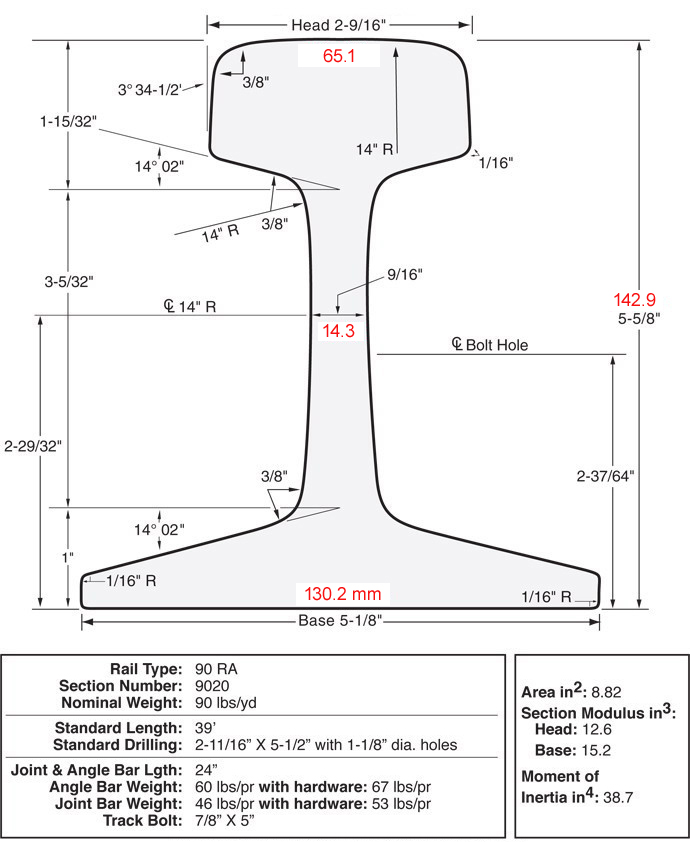

Heigth Rel: 142.9Mm

Lebar Bawah: 130.2Mm

Ketebalan Web: 14.3Mm

Lebar Kepala: 65.1Mm

Panjangnya: 12-30m

Tempat Asal: Mongolia Dalam, Cina (Daratan)

Nama Merek: BISG

Nomor Model: TR45 (90 RA)

Jenis: Rel Berat

Aplikasi: Rel Kereta Api

Berat: 44.64 kg/m

Penggunaan: Jalur kereta api pabrik

Sertifikat: 3.1 MTC/3.2 oleh inspeksi regiester Lloyd

Pasar: Amerika Selatan

Bahan: 900Sebuah

- Deskripsi

- Rel bawah datar standar internasional yang dapat diekspor

- Standar Produksi dan Inspeksi

- Penyelidikan

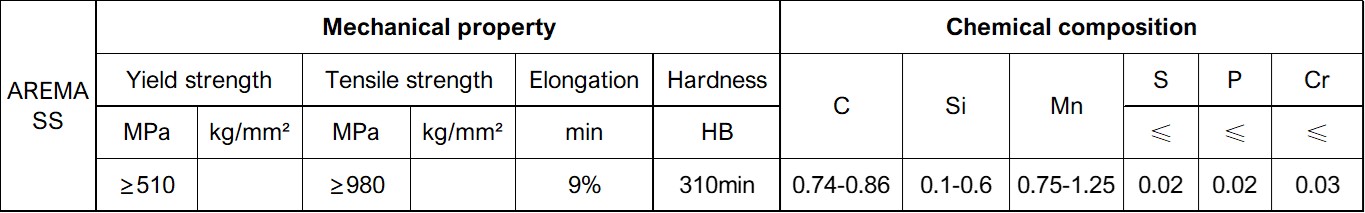

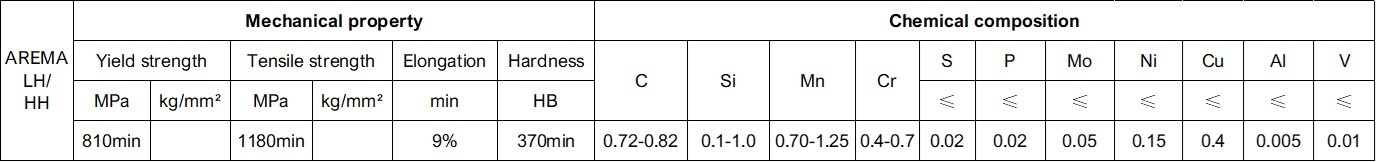

90RA rail also be named TR45 AREMA steel rail, itu banyak digunakan di daerah Amerika, Kita dapat memproduksinya berdasarkan pesanan, MOQ harus 500 Ton. Material memiliki SS dan HH. Panjang 12-25m (39 kaki ke 80 Kaki).

90RA rail is a type of railway track steel rail that adheres to the standards set by the American Railway Engineering and Maintenance-of-Way Association (AREMA). It is commonly used in railway transportation systems, particularly in the United States and other countries that follow AREMA standards.

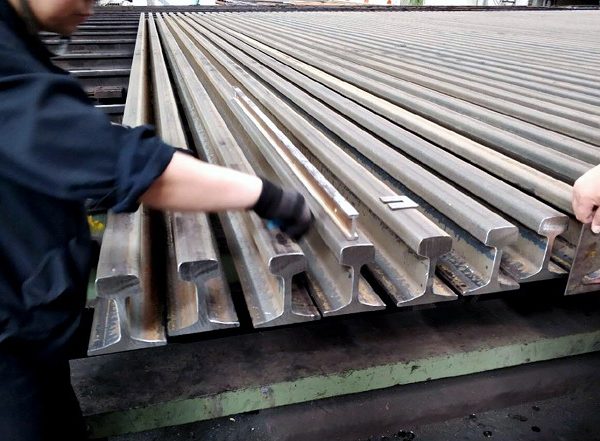

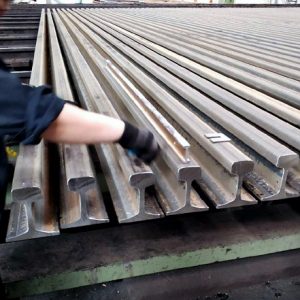

The 90RA rail is made from high-quality carbon steel, which provides it with excellent strength and hardness. The standard dimensions of the rail are 90 pound per yard (kira-kira 45 kilogram per meter) in weight, 130.2 millimeters in bottom width, 142.9 millimeters in height, dan 12-25 panjangnya meter. It also features a specific head shape and profile design that ensures stability and smoothness during operation.

One of the key advantages of the 90RA rail is its excellent wear resistance and impact resistance, which make it suitable for heavy loads and high-speed operations. Selain itu, it has good welding and processing properties, sehingga mudah dipasang dan dirawat.

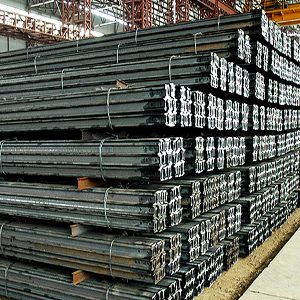

The 90RA rail is widely used in various railway transportation systems, termasuk kereta api jalur utama, Kereta Api Pertambangan, Kereta Api Industri, dan lainnya. Its versatility and durability make it an ideal choice for railway operators who require reliable and long-lasting track infrastructure.

In terms of manufacturing process, the production of 90RA rail involves several steps, including steelmaking, Bergulir, perlakuan panas, and finishing. High-quality raw materials are selected and melted in a furnace before being rolled into the desired shape and size. The rail is then subjected to heat treatment processes such as quenching and tempering to enhance its mechanical properties.

To ensure the quality and safety of the 90RA rail, rigorous testing and inspection procedures are carried out at various stages of production. These tests include non-destructive testing methods such as ultrasonic testing, magnetic particle testing, and radiographic testing, as well as destructive testing methods like tensile testing and bend testing.

Keseluruhan, the 90RA rail is a high-performance railway track steel rail that offers excellent durability, Keandalan, dan kinerja. Sebagai pemasok Cina, we can provide high-quality 90RA rail and other types of railway track products to meet the needs of different customers. If you are interested in learning more about our products or obtaining a quote, Jangan ragu untuk menghubungi kami.

It is worth noting that the 90RA rail is often used in conjunction with other railway track components such as fishplates, Baut, and fasteners to create a complete and secure track system. The selection of these components is critical to ensuring the safe and efficient operation of the railway system.

Sebagai tambahan, the installation and maintenance of the 90RA rail must be carried out by trained and experienced professionals who follow strict safety protocols and guidelines. Regular inspections and maintenance are necessary to identify any potential issues and prevent accidents or derailments.

Keseluruhan, the 90RA rail is a crucial component of modern railway transportation systems, and its quality and performance play a vital role in ensuring the safety and efficiency of railway operations. As a leading supplier of railway track products, we are committed to providing our customers with the highest quality products and services to meet their needs and exceed their expectations.

EN Standar 13674 - 1:2003 terdiri dari dua bagian utama:

− tes kualifikasi dan tes penerimaan

Tes kualifikasi adalah beberapa tes lain yang sebelumnya dilakukan, seperti misalnya, ketangguhan fraktur. Tes penerimaan mencirikan sifat-sifat dari tes yang ditentukan, yang memastikan produksi rel berkualitas tinggi, dan persyaratan pengujian administrasi perkeretaapian.

Kualitas rel didasarkan pada nilai kekerasan yang diukur, di mana mereka memperkenalkan label baru untuk rel baja.

Tes kualifikasi

Pengujian kualifikasi harus dilakukan setidaknya satu dalam lima tahun dan mayor

perubahan teknologi, rel produksi. Tekanan residu pengujian tambahan dilakukan

keluar pada semua jenis rel baja setiap dua tahun maksimum, asalkan longitudinal

laju regangan di rel dapat berjumlah hingga 250 Mpa.

Ujian kualifikasi yang ditentukan adalah sebagai berikut:

- ketangguhan patah tulang

- tingkat pertumbuhan retak kelelahan

− pengujian kelelahan

- Tegangan sisa pada kaki rel

- variasi garis tengah

− kekuatan tarik dan perpanjangan

− segregasi

− persyaratan kualifikasi lainnya

Tes penerimaan

Dalam pengujian penerimaan dilakukan serangkaian tes laboratorium seperti:

- komposisi kimia (konten maksimum dari elemen-elemen berikut: H, O, Al, V, Elemen N dan oligo)

− struktur mikro (meningkatkan x 500)

− derajat dekarburasi lapisan hangus (diizinkan hingga 0.25 Mm)

− kemurnian baja (terutama keberadaan oksida)

- struktur makro (Tes Baumann)

− kekerasan

− kekuatan tarik

Rel pengujian penerimaan lainnya adalah:

− toleransi dimensi

− kriteria (templat kontrol)

− persyaratan inspeksi / toleransi terhadap kualitas internal dan kualitas permukaan

Keadaan internal diperiksa USG dalam kontrol proses berkelanjutan, dan termasuk setidaknya 70% dari kepala dan setidaknya 60% Web.

- Standar UIC 860 V: 1996 - ditentukan empat jenis rel baja perlit dalam kisaran kekuatan tarik dari 700 ke 1300 Mpa.

- EN Standar 13674 - 2003, menyediakan tujuh jenis kekerasan baja perlit dalam kisaran 200 ke 390 HBV, jenis baja sesuai dengan EN 13674, berdasarkan nilai-nilai kekerasan (R 200, R 220, R 260, R 260 Mn, 320 Cr, 350 HT, 350 LHT).