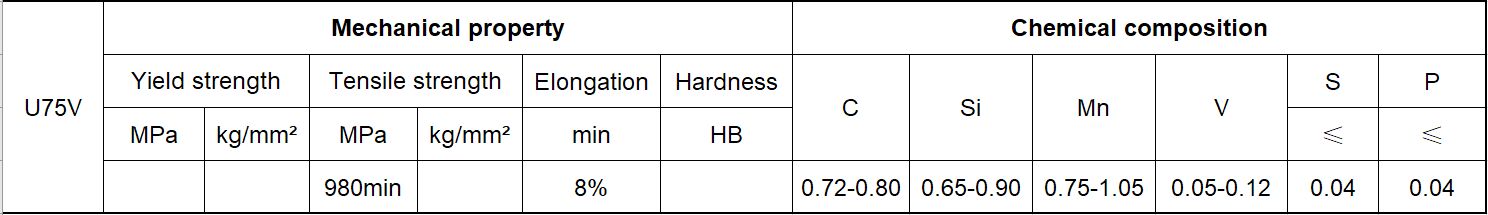

El riel ranurado se utiliza para el tren ligero de la ciudad, caracterizada por la coexistencia de vías y calles férreas, sin durmientes ni escoria. Sin embargo, Por razones de seguridad, La velocidad de carrera es generalmente muy lenta. Por lo tanto, la dureza máxima de este tipo de carril de acero es de alrededor de 300HB, y el material general es U75V.

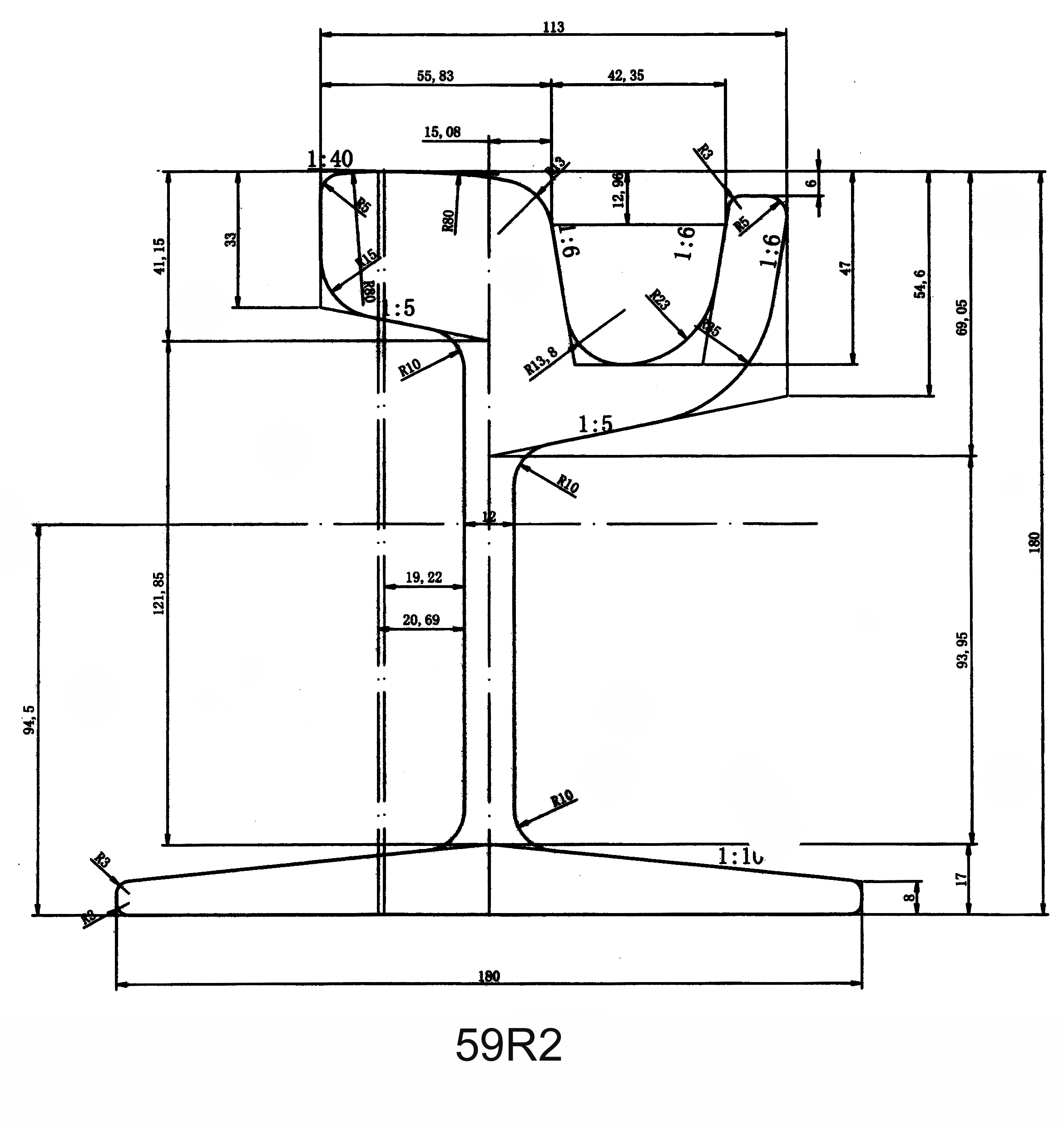

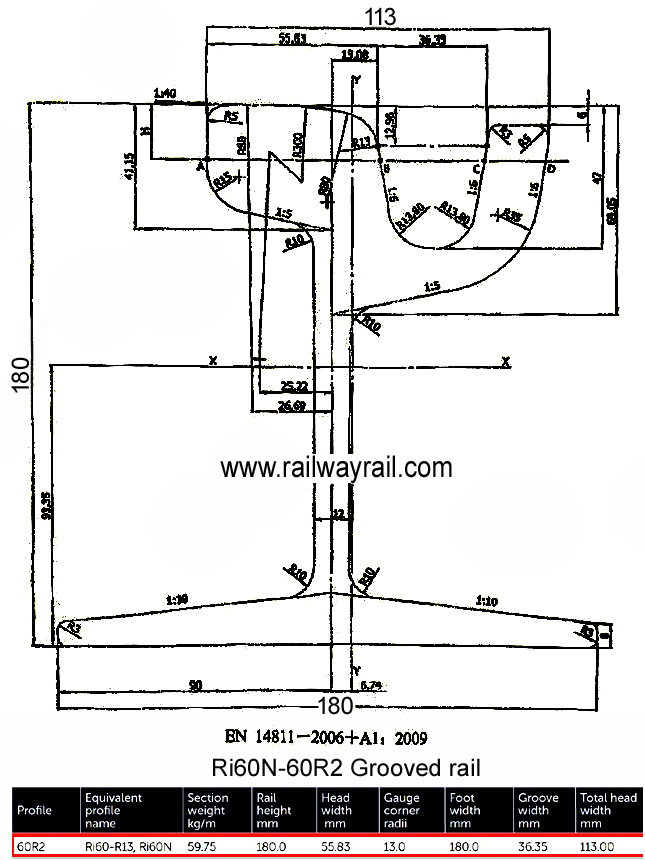

En China solo tiene 59R2 (también se llamará Ri59-R13, Ri59N) y 60R2 (RI60-R13, Ri60N), este es el nuevo tipo de 59R1 y 60R1, the gauge corner radii was updated from R10 to R13, can reduce the wear and tear from wheel to rail. The length can be 12m, 12.5m to 25m, if you need special length, Por favor pregúntenos.

Grooved rail is a type of rail commonly used in city light railways. It is unique in that it allows for the coexistence of railway tracks and streets, eliminating the need for sleepers and slag. Sin embargo, due to safety considerations, the running speed of grooved rail systems is generally kept quite slow. To ensure durability and strength, the maximum hardness of this type of steel rail is typically around 300HB, with the commonly used material being U75V.

In China, there are two main types of grooved rail available: 59R2 (also known as Ri59-R13 or Ri59N) y 60R2 (Ri60-R13 or Ri60N). These rails come in various lengths ranging from 12 meters to 25 Metros.

The utilization of grooved rail has several advantages. En primer lugar, its design allows for the integration of rail lines with existing urban infrastructure, minimizing disruptions to street traffic. This makes it an ideal choice for light rail systems implemented in densely populated cities. Adicionalmente, the absence of sleepers and slag simplifies maintenance work, reducing costs and enhancing operational efficiency.

Although grooved rail offers these benefits, the limited hardness of the steel used necessitates cautious operation at lower speeds. This ensures the safe transportation of passengers while mitigating the wear and tear on the rail system caused by friction with passing vehicles.

It is worth mentioning that developments in rail technology continue to improve the performance of grooved rail systems. Research is ongoing to enhance the hardness and durability of the steel used in these rails, enabling higher running speeds without compromising safety.

En conclusión, grooved rail is a specialized type of rail designed for city light railways where tracks run alongside streets. While safety concerns restrict the running speed, the use of grooved rail provides an efficient and integrated solution for urban transportation. Ongoing advancements in rail technology offer promising prospects for further improving the performance of these systems in the future.

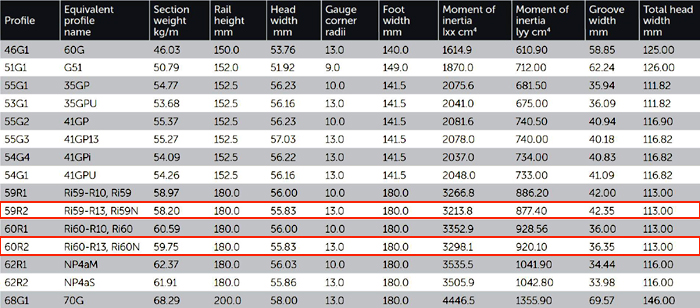

Bienvenido a preguntarnos los rieles de fondo plano estándar internacional como se muestra a continuación: