TR45 steel rail

$860.00 $800.00

Standard: AISI, ASTM, JIS

Grade: 900A/1100

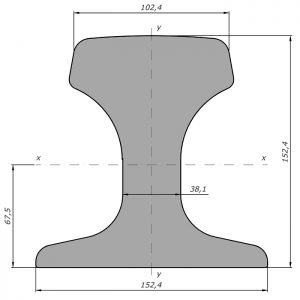

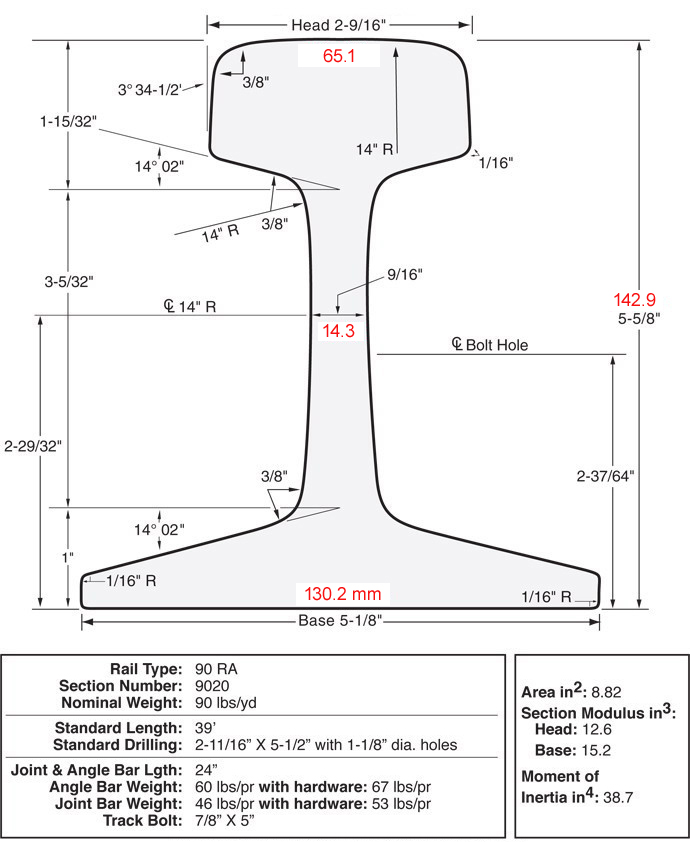

Rail Heigth: 142.9mm

Bottom Width: 130.2mm

Web Thickness: 14.3mm

Head Width: 65.1mm

Length: 12-30m

Model Number: TR45 (90 ARA-A)

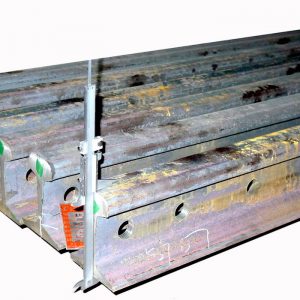

Type: Heavy Rail

Application: Railway Rail

Weight: 44.64 kg/m

Name: TR45 (90 ARA-A) America standard steel rail

Usage: Factory railroad line

Market: South America

Certificate: 3.1 MTC/3.2 by Lloyd’s regiester inspection

Key words: ASTM A759 TR45 steel rail

MOQ: 500 Tons

Warranty: 12 months

HS CODE: 73021000

- Description

- Exportable international standard flat bottom rail

- Inquiry

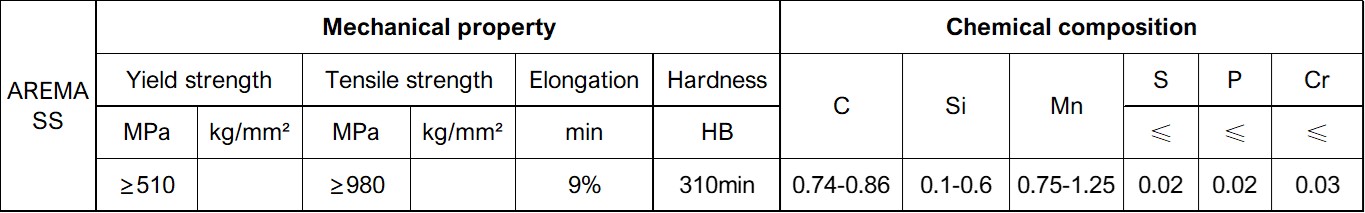

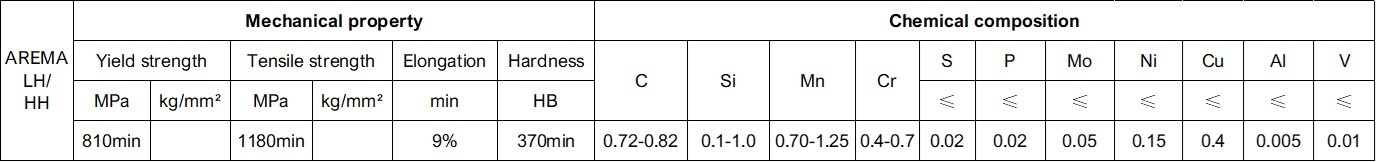

TR45 steel rail just be ASTM A759 90 RA steel rail, it is used for factory railroad in Americas area, we can produce it by order, the MOQ is 500 tons, length 39 to 80 feet, material has SS and HH.

Drawing of TR45 steel rail

TR45 steel rail is a type of steel rail commonly used in railway tracks. It is designed to meet specific requirements and specifications outlined by the industry-standard ASTM A759.

The designation “TR45” refers to the rail’s specific profile and weight. The “TR” stands for “Tee Rail,” indicating its T-shaped cross-section, while the number “45” represents the weight of the rail in kg per meter, which is approximately 90 pounds.

TR45 steel rail is manufactured using high-quality steel and undergoes rigorous manufacturing processes to ensure its strength, durability, and performance. It is designed to support the weight of trains and withstand the dynamic forces exerted during operation.

ASTM A759 is the standard specification for carbon steel crane rails, tram rails, and switch rails. This standard outlines the chemical composition, mechanical properties, and dimensional tolerances for TR45 rail.

Proper installation of TR45 rail is essential for safe and efficient railway operations. Rail fastening systems, such as clips, pads, and bolts, are used to secure the rail to the track bed, ensuring proper alignment and stability.

Regular inspections are conducted to detect signs of wear, deformation, or misalignment. Timely maintenance and repair are crucial to ensure the long-term performance and safety of the rail system.

TR45 steel rail offers excellent dimensional accuracy, straightness, and uniformity. These features contribute to smooth train movement, reducing noise and vibration.

The rail’s robust construction and precise design provide durability and resistance to wear, ensuring reliable performance even under demanding operational conditions. This promotes safe and efficient transportation along the rail line.

TR45 steel rail finds applications in various railway systems, including industrial cranes, tram tracks, and specialized track sections. Its strength and stability make it suitable for supporting heavy loads and facilitating smooth train operations.

In summary, TR45 steel rail adheres to the ASTM A759 standard and is widely used in railway tracks. It is designed to meet specific requirements for strength, durability, and performance. Proper installation, regular inspections, and maintenance are essential for ensuring the rail’s long-term performance and safety in railway operations. TR45 rail offers excellent dimensional accuracy, durability, and resistance to wear, making it suitable for a range of railway applications.