EN13674-1 50E2 steel rail also be named 50EB-T rail, we can produce it by order, the MOQ is 500 tons, hardness 260HB, length can be 12 to 25 meters.

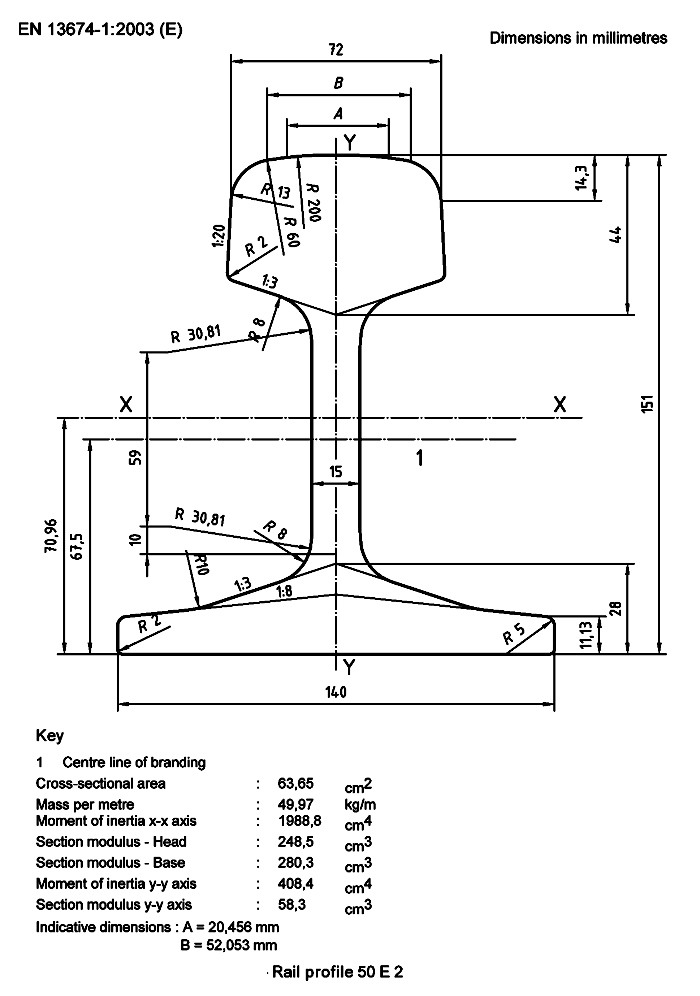

The drawing as below:

EN13674-1 50E2 is a steel rail classification standard in Europe. It specifies the requirements for high-quality rail profiles, in terms of their chemical composition, mechanical properties, and dimensional tolerances. The “50E2” refers to a specific profile type defined by the standard. These rails are commonly used in railway tracks for heavy-duty freight and passenger trains.

50E2 steel rail is a type of standard heavy steel rail used for railway tracks. Its specifications include:

– Rail weight: 50.4 kg/m

– Rail height: 180 mm

– Bottom width: 150 mm

– Head width: 75 mm

– Web thickness: 16.5 mm

– Length: Typically 12-25 meters

50E2 steel rail is commonly used in high-speed railways and mainline tracks, and it meets the requirements of the European standard EN 13674-1.

Installing 50E2 steel rail requires specialized equipment and trained professionals. Here are the general steps for installation:

1. Clear the area and prepare the foundation: The area where the rail is to be installed must be cleared of any debris and leveled. The foundation must also be prepared according to the specifications of the rail manufacturer.

2. Pre-assemble the rail: Before laying the rail, the individual sections should be pre-assembled and joined together with rail joint bars and bolts.

3. Lay the rail: The pre-assembled rail sections are then laid out on the prepared foundation and secured using rail clips that are attached to the sleepers.

4. Adjust the alignment and gauge: The rail must be adjusted for proper alignment and gauge, which is the distance between the two rails on a track. This is done using specialized equipment such as a rail inspector’s gauge and a rail aligning device.

5. Secure the rail: Once the rail is properly aligned and in gauge, it should be fastened securely to the sleepers using rail clips, track bolts, and lock washers.

6. Conduct quality checks: After installation, quality checks such as ultrasonic rail testing and visual inspections should be conducted to ensure the rail is installed correctly and meets safety standards.

It is important to note that installing rail is a complex and dangerous task that should only be performed by trained professionals using appropriate safety measures and equipment.

We can supply all kinds of Chinese standard steel rails as below:

LIGHT RAIL: 4kg/6kg/8kg/9kg/10kg/12kg/15kg/18kg/20kg/22kg/24kg/28kg/30kg steel rail for mine using.

HEAVY RAIL: 33kg/38kg/40kg/43kg/46kg/50kg/60kg/75kg for freight railroad line.

CRANE RAIL: QU70/QU80/QU100/QU120 for Crane Rail running.