DIN536 A100 crane rail in Russia is widely used for heavy-duty lifting applications. This crane rail, defined by the DIN536 standard, represents a crucial component in the infrastructure of industries where the movement of hefty loads is a routine task.

DIN536 A100 crane rail in Russia

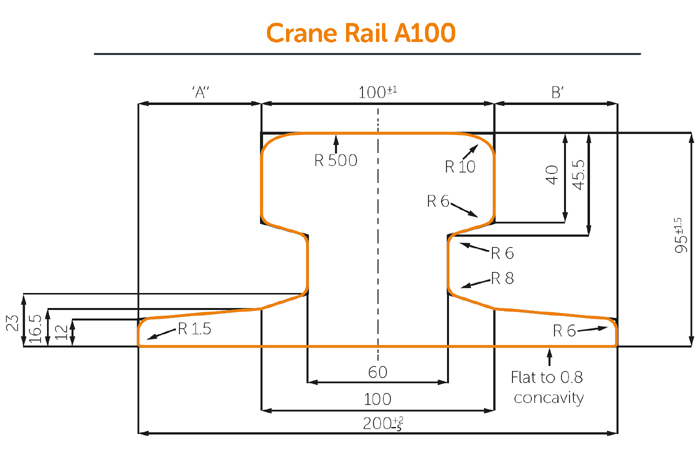

The DIN536 standard specifies the technical requirements and dimensions for crane rails with a profile designation that includes A45, A55, A65, A75, A100, A120, and A150. Among these, the A100 profile is particularly notable for its balance between size, load-bearing capacity, and versatility. The “A” in the designation indicates that the rail is of the “flat-bottomed” type, which is the most common profile for crane rails due to its stability and ease of installation.

The DIN536 A100 crane rail in Russia boasts a railhead width of 100 millimeters, which is substantial enough to provide a broad contact surface for the wheels of cranes and trolleys, thereby ensuring efficient load distribution and reducing the likelihood of excessive wear on both the rail and the wheel material. The height of the rail matches the width, also at 100 millimeters, which is a deliberate design choice to enhance stability and support the vertical loads exerted by the cranes. The base width of the A100 crane rail is 200 millimeters, giving it a solid foundation when mounted onto the rail support structure.

Constructed from high-strength steel, the DIN536 A100 crane rail in Russia is engineered to withstand the high-stress conditions commonly found in heavy industrial environments.

The DIN536 A100 crane rail in Russia is subject to rigorous manufacturing controls to ensure consistency and quality. Producers of the rail are required to adhere to precise tolerances for straightness, height, and overall profile dimensions.

DIN536 A100 crane rail in Russia utility extends across various sectors, including manufacturing plants, where overhead gantry cranes are a common sight; port and intermodal terminals, where container handling gantry cranes require robust rail systems; and large-scale construction projects, where tower cranes and mobile cranes necessitate a reliable ground path. Its durability and ability to handle high-load conditions have made it a preferred choice for projects demanding consistent performance and safety.

In conclusion, the DIN536 A100 crane rail in Russia is a vital component that plays a significant role in the efficiency and safety of industrial operations. Its design, governed by the exacting DIN536 standard, ensures that it meets the highest levels of quality and reliability required by the heavy industries that depend on it. The A100 crane rail’s ability to support the smooth functioning of crane systems makes it indispensable to sectors where large-scale lifting and material handling are essential to productivity and success.

We can supply the international standard flat bottom rails as below:

If you need anyone, please feel free to contact us.