136Rel RE

$850.00 $800.00

- Standard: AREMA, ASTM

- Gred: R260, R350HT

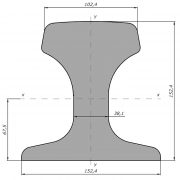

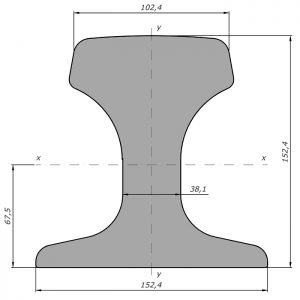

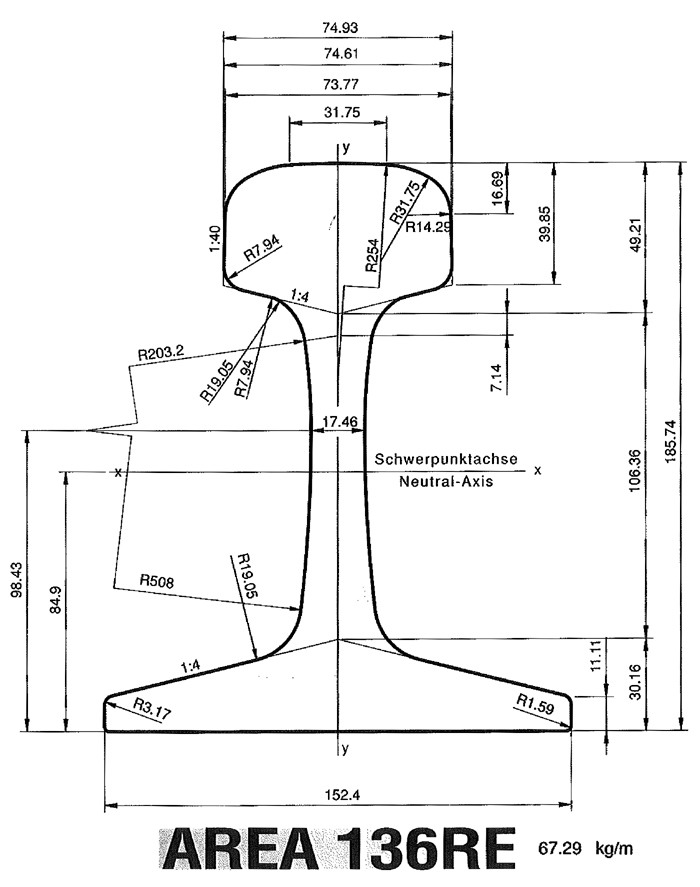

- Rail Heigth: 185.74Mm

- Lebar bawah: 152.4Mm

- Ketebalan Web: 17.46Mm

- Lebar Kepala: 74.61Mm

- Panjang: 12-30m

- Nombor Model: TR68 (136 SEMULA)

- Jenis: Rel Berat

- Permohonan: Rel Kereta Api

- Berat badan: 67.56 kg/m

- Nama: TR68 (136 SEMULA) Amerika kereta api keluli standard

- Sijil: 3.1 MTC/3.2 oleh pemeriksaan regiester Lloyd

- Pasaran: Amerika Selatan

- Penggunaan: Laluan kereta api pengangkutan

- Keterangan

- Rel bawah rata standard antarabangsa yang boleh dieksport

- Standard pengeluaran dan pemeriksaan

- Siasatan

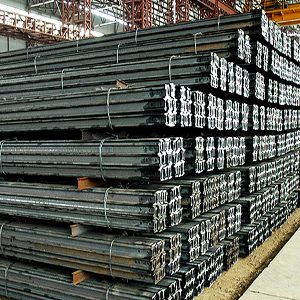

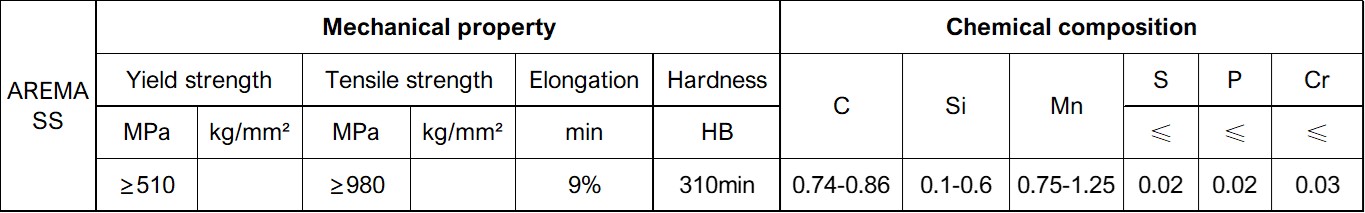

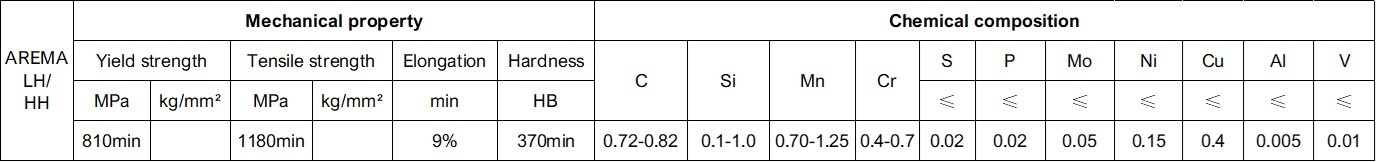

136RE rail also be named TR68 (136 SEMULA) AREMA standard freight rail, it is widely used in Americas area, kita boleh menghasilkannya mengikut pesanan, MOQ hendaklah 500 Tan. The material can be SS and HH, panjang boleh 39 feet to 25 Meter.

136RE rail is a type of steel rail used in railway tracks, primarily in America. The “136SEMULA” designation refers to the weight of the rail, iaitu kira-kira 136 paun setiap halaman (67.4 kg/m). It is classified as a heavy rail and is commonly used for mainline tracks, including both freight and passenger railways.

136RE rail have specific dimensions and profile that conform to industry standards. These rails are typically made from high-strength carbon steel to withstand the heavy loads and stresses imposed by trains. They are installed on either concrete sleepers or wooden ties and secured to the sleepers with various fastening systems, such as clips or spikes.

The exact specifications and properties of 136RE rail may vary slightly depending on the specific manufacturer or region. Walau bagaimanapun, they are designed to provide durability, Kestabilan, and smooth operation for trains.

If you have any further questions about 136RE rail or their application, tolong beritahu saya.

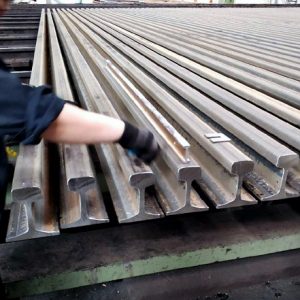

AREA 136RE steel rail is a railway track rail produced according to the standards of the American Railway Engineering and Maintenance of Way Association (AREMA). Here are some basic information about 136RE rail:

1. Bahan: 136RE rail is made of high-quality carbon steel, yang mempunyai kekuatan dan kekerasan yang tinggi.

2. Saiz: The standard size of the AREA 136RE steel rail is 136 paun setiap halaman (Kira 68 kilogram per meter), and it also has a specific head shape and contour design to ensure stability and stability during operation.

3. Characteristics: AREA 136RE steel rail has good wear resistance and impact resistance, and can withstand heavy loads and high-speed operation. Pada masa yang sama, it also has good welding and processing performance, making it easy to install and maintain.

4. Permohonan: 136RE rail is widely used in the railway transportation field in the United States and other countries and regions that use AREMA standards, termasuk kereta api batang, kereta api perlombongan, Kereta Api Perindustrian, Dll.

Keseluruhan, AREA 136RE steel rail is a high-performance railway track rail suitable for various heavy-duty and high-speed railway transportation systems. Sebagai pembekal Cina, we can provide high-quality 136RE rails and other types of railway track products to meet the needs of different customers. If you are interested in this, please feel free to contact us for more information and quotes.

Standard EN 13674 - 1:2003 terdiri daripada dua bahagian utama:

− ujian kelayakan dan ujian penerimaan

Ujian kelayakan adalah beberapa ujian lain yang sebelum ini dijalankan, sebagai contoh, ketangguhan patah. Ujian penerimaan mencirikan sifat ujian yang ditetapkan, yang memastikan pengeluaran rel berkualiti tinggi, dan keperluan ujian pentadbiran kereta api.

Kualiti rel adalah berdasarkan nilai kekerasan yang diukur, di mana mereka memperkenalkan label baru untuk rel keluli.

Ujian kelayakan

Ujian kelayakan mesti dijalankan sekurang-kurangnya satu dalam lima tahun dan utama

perubahan dalam teknologi, rel pengeluaran. Tekanan sisa ujian tambahan dibawa

keluar pada semua jenis rel keluli setiap dua tahun maksimum, dengan syarat bahawa membujur

kadar terikan di rel boleh berjumlah sehingga 250 Mpa.

Peperiksaan kelayakan yang ditetapkan adalah seperti berikut:

− ketangguhan patah

− keletihan retak kadar pertumbuhan

− ujian keletihan

− tekanan sisa dalam kaki kereta api

− variasi garis tengah

− kekuatan tegangan dan pemanjangan

− pengasingan

− keperluan kelayakan lain

Ujian penerimaan

Dalam ujian penerimaan dijalankan satu siri ujian makmal seperti:

− komposisi kimia (kandungan maksimum unsur-unsur berikut: H, O, Al, V, Unsur N dan oligo)

− mikrostruktur (meningkatkan x 500)

− darjah lapisan hangus decarburizing (dibenarkan sehingga 0.25 Mm)

− kesucian keluli (terutamanya kehadiran oksida)

− makrostruktur (Ujian Baumann)

− kekerasan

− kekuatan tegangan

Rel ujian penerimaan lain adalah:

− toleransi dimensi

− kriteria (templat kawalan)

− keperluan pemeriksaan / toleransi untuk kualiti dalaman dan kualiti permukaan

Keadaan dalaman diperiksa ultrasound dalam kawalan proses berterusan, dan termasuk sekurang-kurangnya 70% kepala dan sekurang-kurangnya 60% Web.

- Standard of UIC 860 V: 1996 - ditetapkan empat jenis rel keluli pearlite dalam julat kekuatan tegangan dari 700 Untuk 1300 Mpa.

- Standard EN 13674 - 2003, menyediakan tujuh jenis kekerasan keluli pearlite dalam julat 200 Untuk 390 HBV, jenis keluli mengikut EN 13674, berdasarkan nilai-nilai kekerasan (R 200, R 220, R 260, R 260 Mn, 320 Cr, 350 HT, 350 LHT).