EN13674-1 49E1 steel rail

$850.00 $800.00

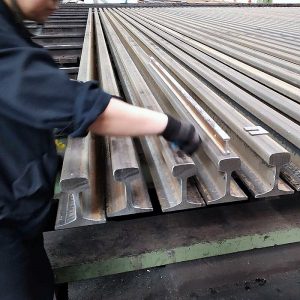

Length: 12 to 36 meters;

Unit weight: 49.4 kg/m;

MOQ: 3000 tons

Delivery term 45 days

Delivery port: Tianjin port

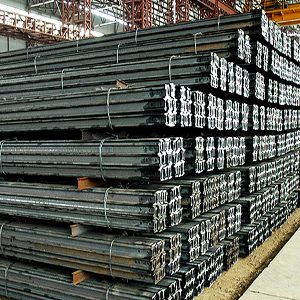

Packing: In bundle by bulk cargo

Payment term: T/T, L/C or Trade assurance by Alibaba

- Description

- Exportable international standard flat bottom rails

- Producing and Inspection standard

- Inquiry

EN13674-1 49E1 steel rail just be S49, we can make roller to produce this type of rail, the MOQ is 3000 tons, the specification as below:

Length: 12 to 25 meters;

Unit weight: 49.39 kg/m;

Production standard: EN13674-1;

Delivery inspection standard: EN13674 for qualifying tests and acceptance tests;

Material: R900A/R1100;

Hardness: R260, R320.

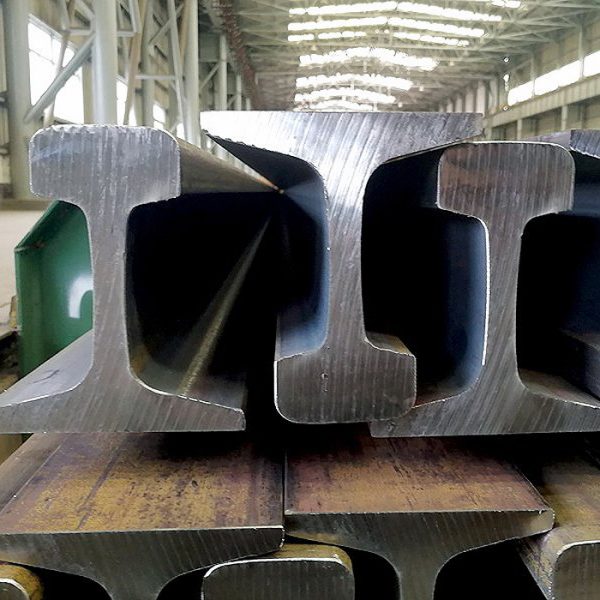

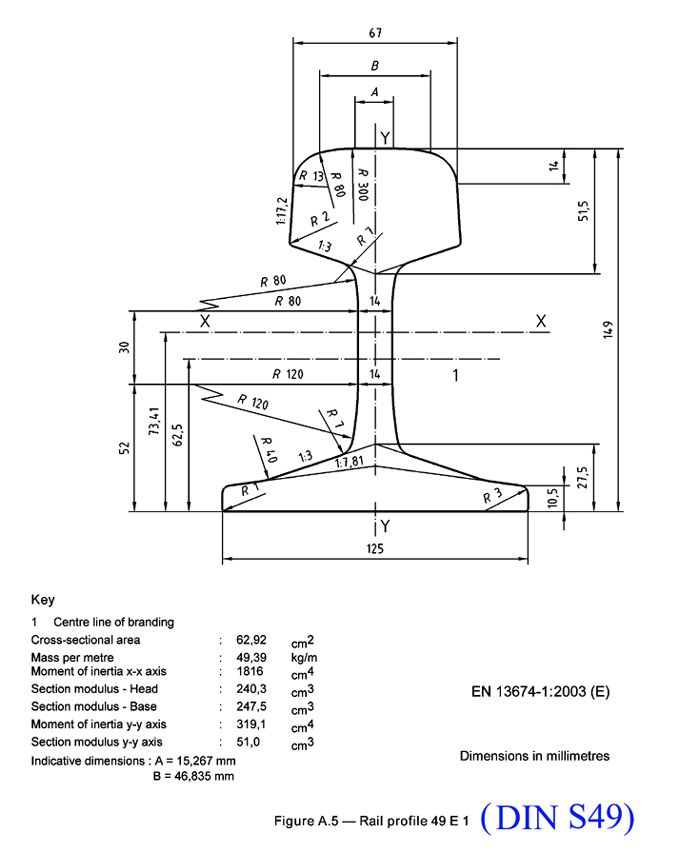

Drawing of EN13674-1 49E1 steel rail

EN13674-1 49E1 steel rail is a type of railway track component that is used in Europe and other regions following the EN standards. This rail profile has specific geometric dimensions, mass, and mechanical properties that make it suitable for various applications in railway transportation.

One of the defining characteristics of EN13674-1 49E1 steel rail is its mass, which is approximately 49 kilograms per meter. The rail profile features a specific shape of the rail head, which provides stable support for train wheels and distributes the load evenly across the rail surface.

The geometry of EN13674-1 49E1 steel rail is designed to ensure compatibility with other railway components, such as sleepers, fastening systems, and rail joints. This promotes interoperability and safety across different railway networks in Europe and other regions that use EN-compliant components.

EN13674-1 49E1 steel rail is commonly used in both mainline and secondary railway tracks to support heavy freight and passenger trains. The rail profile is suitable for various operating speeds and axle loads, making it versatile for different types of railway lines. Moreover, the rail profile can withstand dynamic forces and impact loads, providing reliable support for trains traveling at high speeds.

In addition to its mechanical properties, EN13674-1 49E1 steel rail adheres to established standards and specifications, ensuring consistent quality and manufacturing processes. This promotes reliability and safety in railway transportation, reducing the risk of accidents and disruptions to railway operations.

Overall, EN13674-1 49E1 steel rail is an important component of railway infrastructure in Europe and other regions that follow the EN standards. Its unique characteristics and performance make it suitable for various railway applications, promoting safe and efficient transportation of passengers and goods.

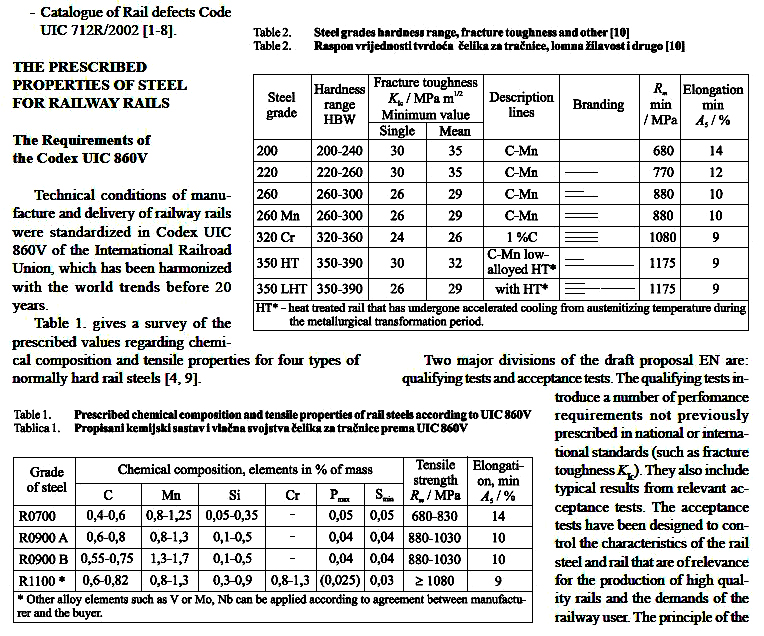

Standard EN 13674 - 1:2003 consists of two main parts:

− qualification test and acceptance tests

Qualification tests are some other tests that were previously carried out, as for example, fracture toughness. Acceptance tests characterize the properties of the prescribed tests, which ensure production of high quality rails, and testing requirements of railway administration.

Quality of rails is based on measured values of hardness, by which they introduced new labels for steel rails.

Qualifying tests

Qualification testing must be conducted at least one in five years and the major

changes in technology, production rails. Additional testing residual stresses are carried

out on all types of steel rails every two year maximum, provided that the longitudinal

strain rate in the rails can amount to up to 250 MPa.

The prescribed qualifying examination is the following:

− fracture toughness

− fatigue crack growth rate

− fatigue testing

− residual stress in rail foot

− variation of centre line

− tensile strength and elongation

− segregation

− other qualification requirements

Acceptance tests

Within acceptance testing is carried out a series of laboratory tests such as:

− chemical composition (the maximum content of the following elements: H, O, Al, V, N and oligo elements)

− microstructure (increasing x 500)

− degree of decarburizing charred layer (allowed up to 0.25 mm)

− purity of steel (especially the presence of oxide)

− macrostructure (Baumann test)

− hardness

− tensile strength

Other acceptance testing rails are:

− dimension tolerances

− criteria (control template)

− inspection requirements / tolerances for to internal quality and surface quality

Internal state is examined ultrasound in a continuous process control, and includes at least 70% of the head and at least 60% web.

- Standard of UIC 860 V: 1996 - prescribed four types pearlite steel rails in the range of tensile strength from 700 to 1300 MPa.

- Standard EN 13674 - 2003, provides seven types pearlite steel hardness in the range 200 to 390 HBV, types steel in accordance with EN 13674, based on the values of hardness (R 200, R 220, R 260, R 260 Mn, 320 Cr, 350 HT, 350 LHT).