Rel keluli TR30

$700.00 $660.00

Standard: ASTM, BS, GB, JIS

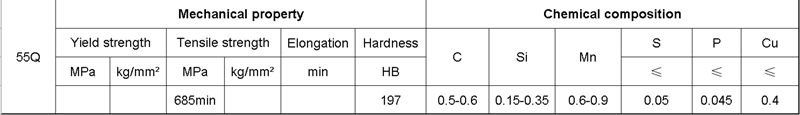

Gred: Q235B/55Q

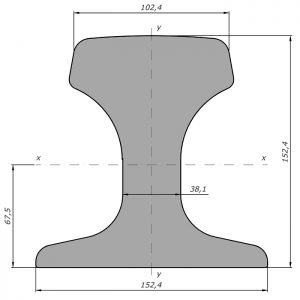

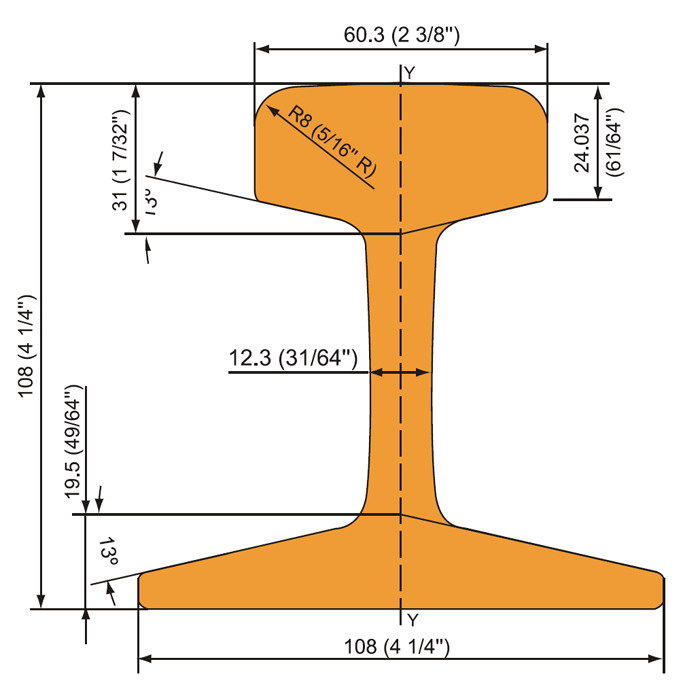

Rail Heigth: 108Mm

Lebar bawah: 108Mm

Ketebalan Web: 12.3Mm

Lebar Kepala: 60.33Mm

Panjang: 6m/8m/10m

Tempat Asal: Hebei, China (Darat)

Nama Jenama: Hangang

Nombor Model: TR30

Jenis: Rel Cahaya

Permohonan: Rel Kereta Api

Berat badan: 30.1kg/m

Sekunder atau tidak: Bukan menengah

Diameter Lubang Bolt: 24Mm

Nama: TR30 Kereta api keluli ringan standard Amerika

Nama produk: 30kg / m rel keluli lignt

Nama lain: Kereta api perlombongan

Ketinggian bebibir pusat: 19.45Mm

Ketinggian kepala: 30.95Mm

Pasaran: Negara-negara membangun

Penggunaan: Kereta saya berjalan kereta api

Sijil: ISO9001:2008

Hartanah: TR30 Kereta api keluli ringan standard Amerika

MOQ: 20 Tan/Ton

- Keterangan

- Producing and inspection standard

- Rel bawah rata standard antarabangsa yang boleh dieksport

- Siasatan

TR30 steel rail is used for mine railroad line or light rail track, Kami sentiasa mempunyai stok ini, boleh menghantarnya tepat pada masanya. Bahan ini mempunyai Q235 dan 55Q, panjang 6m, 8m dan 10m.

TR30 steel rail is a type of steel rail used in railway tracks. It is primarily used in light rail transit (LRT) systems and urban transportation networks. The “TR” in TR30 stands for “Transit Rail,” indicating its specific application in transit systems.

TR30 rail is designed to meet the requirements of light rail transit, which typically involves lower axle loads and slower train speeds compared to heavy rail systems. Here are some key characteristics and features of TR30 steel rail:

1. Profil: TR30 rail has a specific profile that conforms to industry standards. It is typically characterized by its head width, Ketinggian, and base width, which determine its load-bearing capacity and compatibility with other rail components.

2. Berat badan: TR30 rail typically weighs around 30 kilogram per meter. Its relatively lighter weight allows for easier handling during installation and maintenance.

3. Bahan: TR30 rail is commonly made from high-quality steel, which provides excellent strength, Ketahanan, dan ketahanan terhadap haus dan keletihan. The exact specifications of the steel composition may vary depending on regional and industry standards.

4. Pemasangan: TR30 rail is installed on concrete sleepers or wooden ties using appropriate fastening systems, such as clips or spikes. The rail joints are secured to ensure a seamless track alignment and smooth train operations.

5. Aplikasi: TR30 rail is specifically designed for light rail transit systems, including urban trams, streetcars, and light metro systems. It is suitable for tracks with lower traffic volumes and lighter trains.

6. Penyelenggaraan: Regular inspection and maintenance are essential for ensuring the safe and efficient operation of TR30 rail tracks. This includes monitoring wear and tear, replacing worn-out sections, and maintaining proper rail alignment.

TR30 steel rail offers several advantages for light rail transit systems. Its lighter weight makes it easier to handle during installation and maintenance activities. The rail’s design and material properties ensure a smooth and comfortable ride for passengers. Selain itu, TR30 steel rail is designed to withstand the specific load and speed requirements of light rail transit, making it a reliable choice for urban transportation networks.

It’s worth noting that specific rail standards and specifications may vary between different countries and regions. Itu, it is important to consult local rail authorities or industry guidelines for precise information on TR30 steel rail and its application in specific locations.

Standard EN 13674 - 1:2003 terdiri daripada dua bahagian utama:

− ujian kelayakan dan ujian penerimaan

Ujian kelayakan adalah beberapa ujian lain yang sebelum ini dijalankan, sebagai contoh, ketangguhan patah. Ujian penerimaan mencirikan sifat ujian yang ditetapkan, yang memastikan pengeluaran rel berkualiti tinggi, dan keperluan ujian pentadbiran kereta api.

Kualiti rel adalah berdasarkan nilai kekerasan yang diukur, di mana mereka memperkenalkan label baru untuk rel keluli.

Ujian kelayakan

Ujian kelayakan mesti dijalankan sekurang-kurangnya satu dalam lima tahun dan utama

perubahan dalam teknologi, rel pengeluaran. Tekanan sisa ujian tambahan dibawa

keluar pada semua jenis rel keluli setiap dua tahun maksimum, dengan syarat bahawa membujur

kadar terikan di rel boleh berjumlah sehingga 250 Mpa.

Peperiksaan kelayakan yang ditetapkan adalah seperti berikut:

− ketangguhan patah

− keletihan retak kadar pertumbuhan

− ujian keletihan

− tekanan sisa dalam kaki kereta api

− variasi garis tengah

− kekuatan tegangan dan pemanjangan

− pengasingan

− keperluan kelayakan lain

Ujian penerimaan

Dalam ujian penerimaan dijalankan satu siri ujian makmal seperti:

− komposisi kimia (kandungan maksimum unsur-unsur berikut: H, O, Al, V, Unsur N dan oligo)

− mikrostruktur (meningkatkan x 500)

− darjah lapisan hangus decarburizing (dibenarkan sehingga 0.25 Mm)

− kesucian keluli (terutamanya kehadiran oksida)

− makrostruktur (Ujian Baumann)

− kekerasan

− kekuatan tegangan

Rel ujian penerimaan lain adalah:

− toleransi dimensi

− kriteria (templat kawalan)

− keperluan pemeriksaan / toleransi untuk kualiti dalaman dan kualiti permukaan

Keadaan dalaman diperiksa ultrasound dalam kawalan proses berterusan, dan termasuk sekurang-kurangnya 70% kepala dan sekurang-kurangnya 60% Web.

- Standard of UIC 860 V: 1996 - ditetapkan empat jenis rel keluli pearlite dalam julat kekuatan tegangan dari 700 Untuk 1300 Mpa.

- Standard EN 13674 - 2003, menyediakan tujuh jenis kekerasan keluli pearlite dalam julat 200 Untuk 390 HBV, jenis keluli mengikut EN 13674, berdasarkan nilai-nilai kekerasan (R 200, R 220, R 260, R 260 Mn, 320 Cr, 350 HT, 350 LHT).