QU120 and KP120 crane rails are indeed similar but have different standards. QU120 is a Chinese standard rail, while KP120 is a Russian GOST standard rail. Both rails have similar physical dimensions, but the composition and properties of their materials differ.

QU120 crane rail is widely used in various crane applications due to its high load-bearing capacity, good wear resistance, and favorable welding properties.

KP120 crane rail is commonly used in Russia and other countries that follow the GOST standard. It offers excellent durability, reliability, and resistance to wear and tear, making it suitable for a wide range of crane applications.

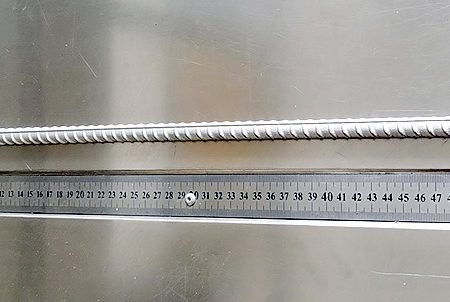

QU120 crane rail is a Chinese standard rail that is widely used in various crane applications due to its high load-bearing capacity, good wear resistance, and favorable welding properties. The rail is manufactured according to YBT5055-93 standard, which specifies the requirements for its chemical composition, mechanical properties, and tolerances. The QU120 crane rail has a standard length of 12 meters and a weight of 118 kg per meter. Its cross-sectional dimensions are 170mm in height, 120mm in head width and bottom width, and 70mm in waist thickness. The rail’s moment of inertia is 4260 cm4, its section modulus is 320 cm3, and its allowable bending stress is 196 MPa. This rail offers excellent weight-bearing capacity, strength, and durability, making it ideal for heavy-duty crane operations.

KP120 crane rail is a Russian standard rail that is widely used in various industrial and crane applications in Russia and other countries that follow the GOST standard. The rail is manufactured according to GOST 4121-96, which specifies the requirements for its chemical composition, mechanical properties, and tolerances. The KP120 crane rail has a standard length of 12 meters and a weight of 117 kg per meter. Its cross-sectional dimensions are 170mm in height, 120mm in head width and bottom width, and 70mm in waist thickness. The rail’s moment of inertia is 4249 cm4, its section modulus is 318 cm3, and its allowable bending stress is 210 MPa. This rail offers excellent strength, durability and load-bearing capacity, making it ideal for use in various heavy-duty crane operations.

While QU120 and KP120 crane rails have different standards, their physical dimensions and properties are very similar. The differences lie mainly in the composition of their materials. Both rails offer high load-bearing capacity, excellent strength, durability, and reliability, making them suitable for various industrial and crane applications.

Welcome to ask us the international standard flat bottom rails as below: