EN14811 59R2 city tram grooved rail is a European Standard that specifies the characteristics of railway applications, particularly grooved and associated rails for use mainly in urban transport systems like trams or city railways. The “59R2” refers to a specific profile of grooved rail that is defined within this standard.

EN14811 59R2 city tram grooved rail

Grooved rails, also known as Vignole rails, are an essential component of modern tramway infrastructure. They feature a distinctive groove along the running surface which houses the flanged wheels of trams, allowing them to run on tracks while maintaining stability and guidance. The design allows for smoother transitions between road and rail sections, making it ideal for trams operating in urban environments where they may share space with other vehicles or have dedicated lanes.

EN14811 59R2 city tram grooved rail, also known as girder rails, are designed with a groove or channel that allows the flanges of tram wheels to run smoothly within the rail, while the tread of the wheel runs on the head of the rail. This design is particularly suitable for street-running trams or light rail vehicles where the rails are embedded into the road surface and must accommodate other road traffic.

EN14811 59R2 city tram grooved rail lays out comprehensive guidelines covering several key aspects:

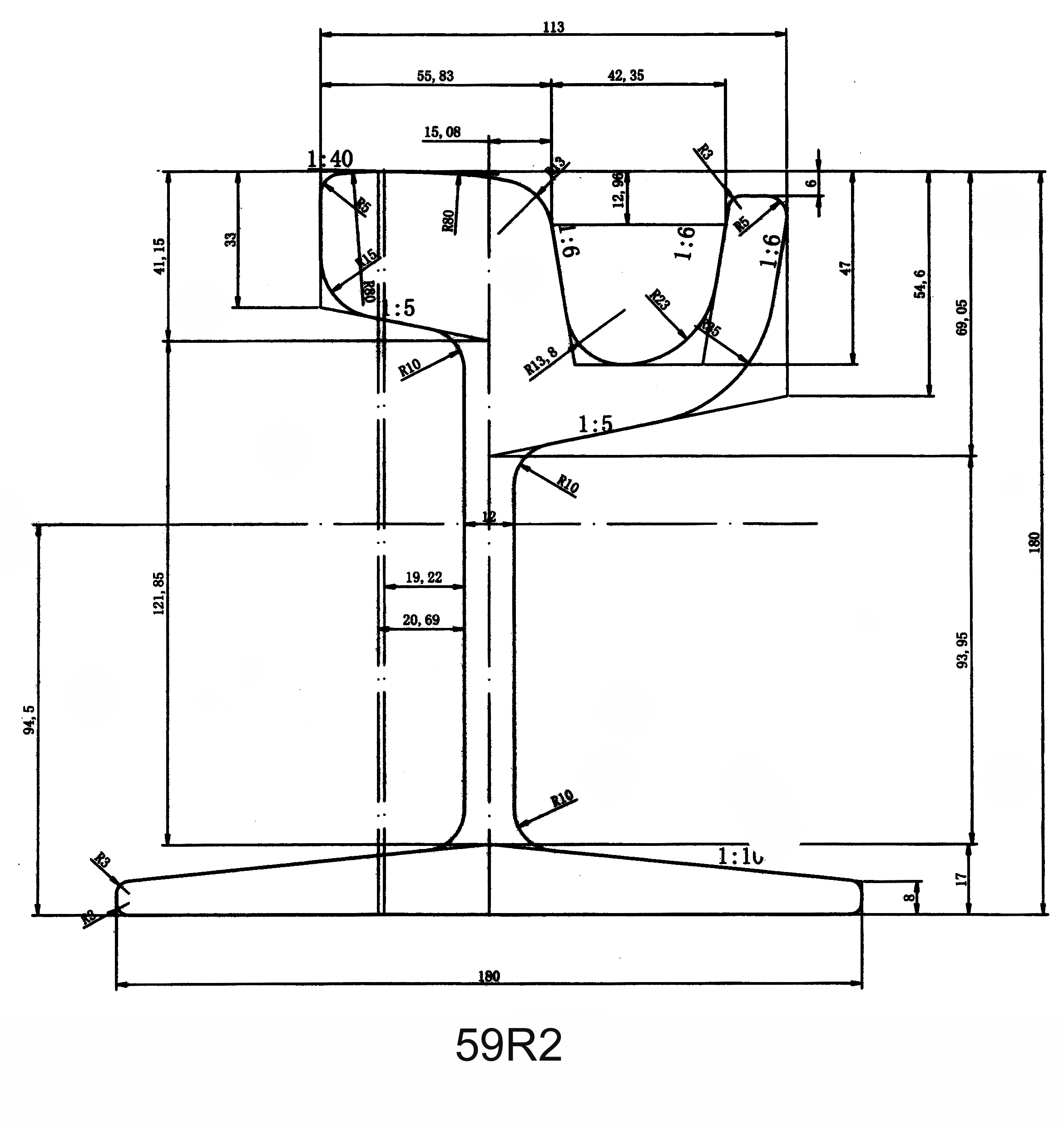

1. Dimensional Requirements: The standard meticulously prescribes the dimensions and tolerances of various parts of the rail, including the web, foot, head, and groove width and depth. These measurements ensure compatibility with tram wheel profiles and maintain a consistent interface for safe operation.

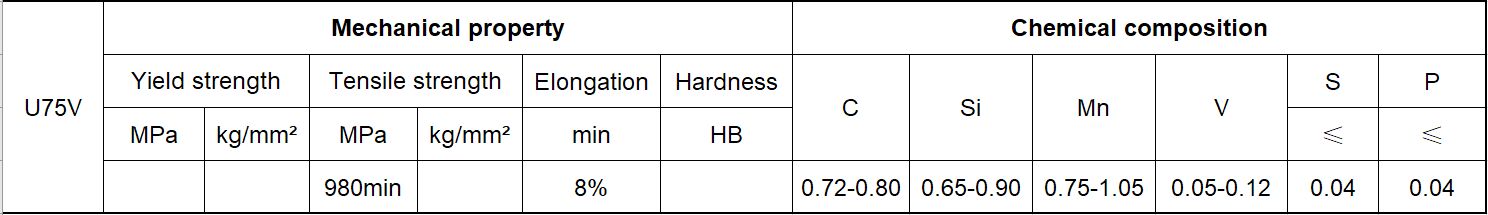

2. Material Specifications: It specifies the steel grades and their corresponding metallurgical properties required for the production of grooved rails. High-quality materials are essential to withstand the mechanical stresses caused by the weight of the trams, braking forces, and cyclic loading over time, as well as resist corrosion from environmental factors.

3. Manufacturing Processes: The standard outlines the manufacturing processes, such as rolling, heat treatment, and finishing, to guarantee the structural integrity and longevity of the rails. It also includes requirements for non-destructive testing methods like ultrasonic testing to detect internal defects.

4. Performance Criteria: EN14811 59R2 sets performance thresholds for parameters like hardness, toughness, fatigue strength, and wear resistance. Compliance with these criteria ensures the rails can endure continuous service under heavy loads and varying weather conditions without premature failure.

5. Installation and Maintenance: Although not directly within the scope of this standard, adherence to EN14811 59R2 indirectly influences the installation and maintenance practices, as compliant rails should be installed correctly and maintained according to their designed characteristics.

6. Testing Methods: The standard provides clear instructions for conducting tests to verify compliance, such as static and dynamic load testing, to confirm the rail’s ability to meet operational demands without deformation or breakage.

In essence, EN14811 59R2 city tram grooved rail used in city tram networks offer optimal safety, durability, and efficiency. By adhering to this standard, tram operators and infrastructure providers can ensure that their systems comply with stringent European regulations and best practices, thereby contributing to the reliability, comfort, and sustainability of urban public transport systems.

We can supply the international standard flat bottom rails as below:

If you need anyone, please feel free to contact us.