DIN 536 A75 crane rail is a specific type of crane rail that conforms to the DIN 536 standard. The “A75” designation refers to its profile shape and weight per meter. This rail is commonly used in various applications such as overhead cranes, gantry cranes, and other heavy-duty industrial rail systems. It has specific dimensions and mechanical properties that make it suitable for supporting heavy loads and providing smooth movement for cranes.

The detailed specifications of DIN 536 A75 crane rail are as follows:

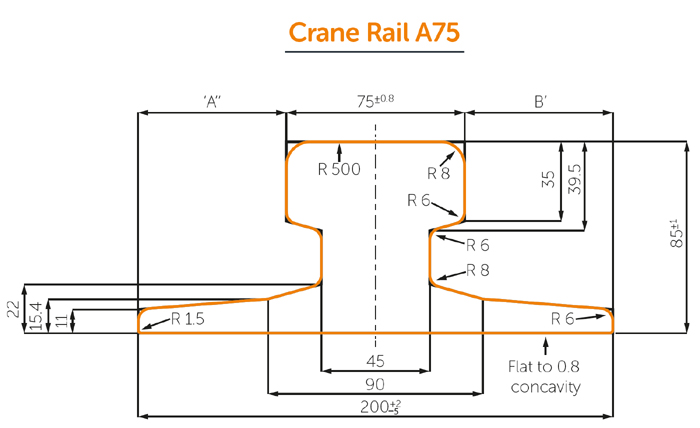

- Profile: The rail has an “A” profile, the height is low and base is widely, looked more stable for crane running.

- Weight per meter: The rail weighs approximately 74.3 kg per meter.

- Head width: The head width of the rail is about 75 mm.

- Height: The rail has a height of approximately 85 mm.

- Base width: The base width measures around 200 mm.

- Web thickness: The web thickness is about 45 mm.

- Overall length: The standard length of DIN 536 A75 crane rail is typically 12 meters.

- Material: The material is U71Mn, can provides strength and durability for heavy-load applications.

DIN 536 A75 crane rail can be used in various countries around the world. The DIN standard is widely recognized and followed in many European countries, including Germany, France, Italy, Spain, and others. DIN standards have been adopted by other countries outside of Europe.

DIN 536 A75 crane rail is commonly used in various industrial settings and applications that require the movement of heavy loads using cranes. Such as:

- Ports and harbors: DIN 536 A75 crane rail is often used in port areas for container handling, shipbuilding, and other related activities.

- Steel plants: The rail is utilized in steel mills and plants for transporting heavy materials and products within the facility.

- Construction sites: It can be seen in construction sites where cranes are used for lifting and moving heavy components, such as prefabricated building elements.

- Manufacturing facilities: Industries like automotive, aerospace, and machinery manufacturing use this rail for the efficient movement of heavy equipment and components.

- Warehouses and logistics centers: DIN 536 A75 crane rail may be present in warehouses or distribution centers where overhead cranes are used for material handling.

The rail can be used in the areas that require efficient and reliable crane operations. The usage depends on the specific needs of each industry or project.

We can supply the international standard flat bottom rails as below: