Columbia DIN536-1991 A120 crane rail is a type of rail that is specifically designed for use in heavy-duty crane systems. It is widely used in various industries such as ports, shipyards, steel mills, and construction sites, where high load capacity and durability are crucial.

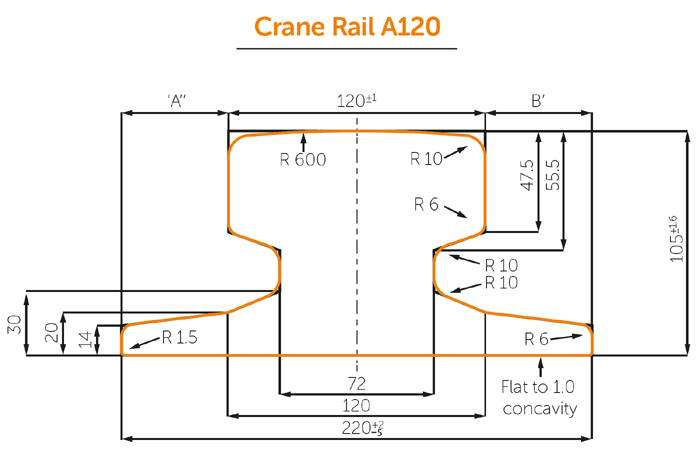

Drawing of Columbia DIN536-1991 A120 crane rail

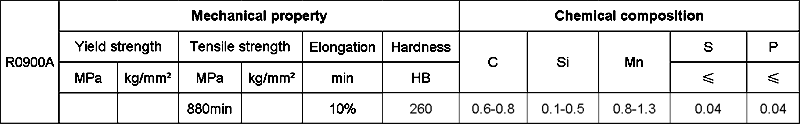

Material of Columbia DIN536-1991 A120 crane rail

The DIN536-1991 A120 crane rail is manufactured according to the DIN standards, which ensures its quality and reliability. It is made from high-quality steel, which undergoes a stringent manufacturing process to ensure its strength and durability. The rail is hot-rolled and has a uniform cross-section, which allows for smooth and efficient movement of cranes along its length.

One of the key features of the DIN536-1991 A120 crane rail is its high load capacity. It is designed to withstand heavy loads and provide excellent performance under extreme conditions. This makes it suitable for handling heavy cargo and equipment in industrial environments. The rail is also designed to withstand the dynamic forces generated by moving cranes, ensuring safe and efficient operations.

The DIN536-1991 A120 crane rail has excellent wear resistance properties. It is designed to withstand the constant abrasion and impact caused by the movement of cranes. This ensures that the rail maintains its structural integrity and functionality over a long period, reducing the need for frequent replacements and maintenance.

Another notable feature of the DIN536-1991 A120 crane rail is its easy installation process. The rail comes with pre-drilled holes for fastening, which simplifies the installation process and reduces the time required for setting up the crane system. This allows for quick and efficient establishment of crane tracks, minimizing downtime and maximizing productivity.

The DIN536-1991 A120 crane rail is also compatible with various crane systems and accessories. It can be used with different types of cranes, such as overhead cranes, gantry cranes, and jib cranes, making it a versatile choice for various applications. The rail is also compatible with various crane accessories, such as rail clamps, rail clips, and rail pads, which further enhance its functionality and performance.

In conclusion, the Columbia DIN536-1991 A120 crane rail is a high-quality rail that is designed for heavy-duty crane systems. It offers excellent load capacity, wear resistance, and easy installation, making it a reliable choice for industries that require efficient and safe crane operations.

We can supply the international standard flat bottom rails as below:

If you need anyone, please feel free to contact us.