Chile DIN536 A120 crane rail is a specific type of rail used in the construction and operation of cranes in Chile. This rail is manufactured according to the DIN 536 standard, which ensures its high quality and reliability. The A120 is suitable for heavy-duty applications.

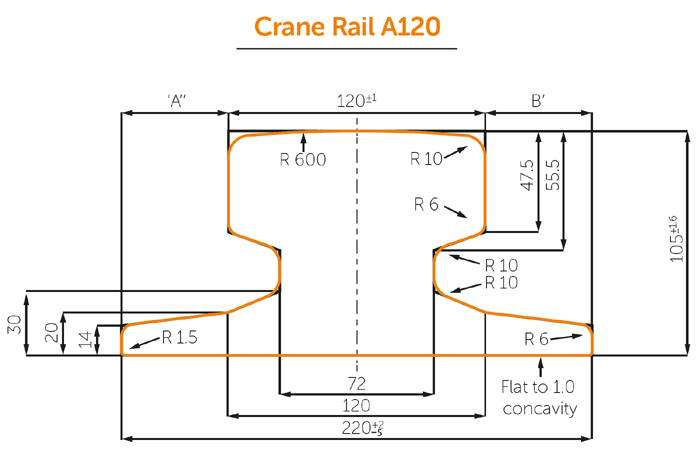

Drawing of Chile DIN536 A120 crane rail

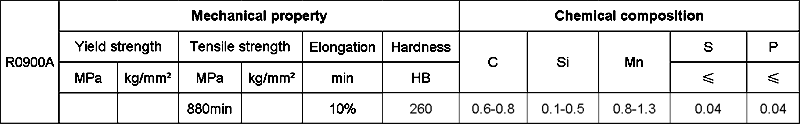

One of the key features of the Chile DIN536 A120 crane rail is its durability. It is constructed using high-quality steel, which provides excellent strength and resistance to wear and tear. This rail can withstand heavy loads and constant use, making it ideal for the demanding conditions of crane operations. Its robust construction ensures the rail’s longevity, reducing the need for frequent replacements and maintenance.

In addition to its durability, the Chile DIN536 A120 crane rail is designed to provide smooth and reliable movement for cranes. The rail has a consistent cross-sectional shape, allowing cranes to move along it with minimal friction and resistance. This ensures efficient and precise crane operations, increasing productivity and reducing downtime.

To enhance the performance of the Chile DIN536 A120 crane rail, rubber pads are supplied as a matching accessory. These rubber pads are placed between the rail and the crane’s wheels or tracks, providing cushioning and reducing noise during movement. The rubber pad also helps to distribute the load evenly, reducing the stress on the rail and prolonging its lifespan. By using the matched rubber pad, crane operators can ensure smooth and quiet operations while minimizing the risk of rail damage.

Furthermore, the 9220 clamp is another accessory that complements the Chile DIN536 A120 crane rail. The clamp is used to secure the rail to the supporting structure, ensuring its stability and preventing any movement or displacement. This clamp is specifically designed to fit the dimensions of the A120 rail, providing a secure and reliable connection.

Overall, the Chile DIN536 A120 crane rail, along with the matched rubber pad and 9220 clamp, offers a comprehensive solution for the construction and operation of cranes in Chile. Its durability, smooth movement, and secure installation make it a reliable choice for various crane applications. Whether it is used in construction sites, ports, or industrial facilities, this rail system provides a solid foundation for efficient and safe crane operations.

We can supply the international standard flat bottom rails as below:

If you need anyone, please feel free to contact us.