The Russia DIN536 A75 crane rail is a type of steel rail that is widely used in crane tracks for various industrial applications. It is specifically designed to withstand heavy loads and provide stability and durability in crane operations.

Russia DIN536 A75 crane rail

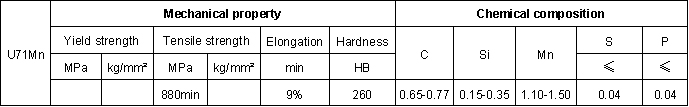

The A75 crane rail is manufactured and conforms to the DIN536 standard, which ensures its high quality and adherence to industry specifications. It is made from high-strength steel, which allows it to handle heavy loads and resist deformation under intense pressure. The rail undergoes a rigorous manufacturing process, including heat treatment and strict quality control measures, to ensure its superior performance and longevity.

One of the key features of the DIN536 A75 crane rail is its unique profile, which is designed to maximize strength and stability. It has a wide top flange and a thick base, providing optimal load distribution and reducing the risk of rail failure or deformation. The rail also has a smooth running surface, minimizing friction and wear, and facilitating smooth and efficient crane movement.

The A75 crane rail is known for its ability to withstand high impact and dynamic loads, making it suitable for heavy-duty industrial applications. It is designed to handle the demanding requirements of crane operations, minimizing downtime and ensuring safe and efficient lifting and moving of heavy loads. The rail’s strength and durability contribute to increased productivity and reduced maintenance costs.

Moreover, the DIN536 A75 crane rail is highly versatile and compatible with various types of cranes and lifting equipment. It can be easily integrated into existing crane tracks, providing a cost-effective solution for upgrading or expanding crane systems. The rail’s standardized dimensions and profiles also ensure compatibility with other international crane rail systems, facilitating seamless integration and interoperability.

Additionally, the A75 crane rail is designed to withstand harsh environmental conditions, including extreme temperatures, corrosive substances, and heavy moisture. It is treated with protective coatings and finishes to enhance its resistance to corrosion and increase its lifespan. This makes it suitable for both indoor and outdoor crane applications, ensuring long-term performance and reliability.

In conclusion, the Russia DIN536 A75 crane rail is a high-quality and reliable steel rail that is specifically designed for crane track applications. Its superior strength, durability, and versatility make it an ideal choice for heavy-duty industrial environments. With its ability to withstand high impact loads and harsh environmental conditions, the A75 crane rail ensures safe and efficient crane operations, contributing to increased productivity and reduced downtime.

We can supply the international standard flat bottom rails as below:

If you need anyone, please feel free to contact us.