Title: An In-Depth Introduction to Saudi Arabia QU120 Crane Rail

Saudi Arabia QU120 crane rail is a heavy-duty rail profile commonly used in industrial and construction applications, particularly for overhead cranes, gantry cranes, and other heavy load-bearing structures.

In Saudi Arabia, the demand for robust infrastructure development and the growth of industries such as mining, steel, and transportation has led to an increased need for reliable crane rail solutions like the QU120.

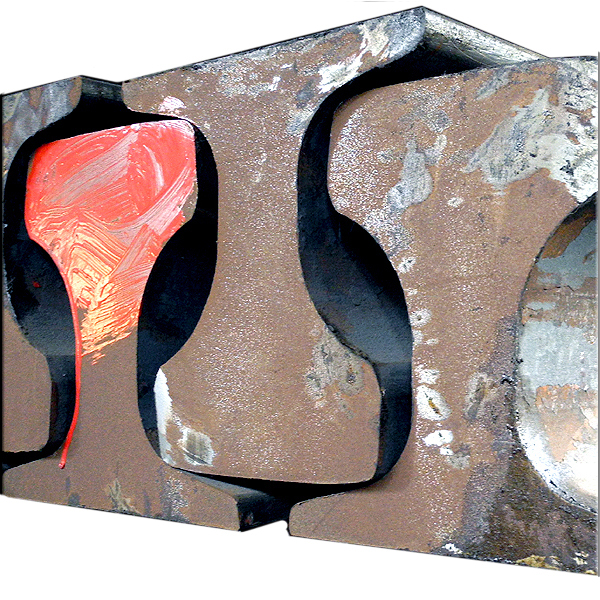

Saudi Arabia QU120 crane railManufactured from high-quality steel, the Saudi Arabia QU120 crane rail is designed to withstand high stress and loads. Its dimensions and specifications are tailored to provide a stable and secure track for the wheels of cranes to move upon. The QU120 denotes the weight of the rail, which is typically around 120 kilograms per meter, signifying its capacity to support heavy machinery.

Saudi Arabian industrial sectors are rapidly expanding, and the QU120 crane rail plays a crucial role in the development of facilities that require heavy lifting and precise movements. The rail’s profile allows for smooth transit of crane wheels, minimizing vibration and enhancing operational efficiency.

This is particularly important for projects where precision is paramount, such as in the construction of high-rise buildings or the installation of heavy equipment in manufacturing plants.

To ensure the safety and longevity of crane operations, theSaudi Arabia QU120 crane rail must be installed with precision. This entails proper alignment, secure fastening, and regular maintenance. In Saudi Arabia, there are stringent standards and regulations in place to govern the installation and use of crane rails, reflecting the country’s commitment to safety and quality in its industrial growth.

Saudi Arabia QU120 crane rail boasts a high load-bearing capacity, resistance to wear and tear, and longevity, making it an ideal choice for installations in ports, shipyards, steel mills, and large construction sites across Saudi Arabia. The country’s push towards economic diversification and its Vision 2030 initiative have led to an increase in the demand for such heavy industrial components.

Saudi Arabia QU120 crane rail is designed with a flat bottom, which is a typical characteristic of crane rails. This design ensures stability and allows for easier mounting and alignment, which is crucial for the safety and efficiency of crane operations. The dimensions and mechanical properties of the QU120 rail follow international standards, ensuring compatibility and reliability in a global industrial context.

In Saudi Arabia, the procurement and installation of the QU120 crane rail involve stringent quality checks and adherence to both national and international standards. Suppliers and contractors are required to ensure that the rails are installed with precision to mitigate risks and to maintain the functionality of the crane systems over extended periods.

Safety is a paramount concern when dealing with heavy machinery, and the QU120 crane rail is no exception. Regular inspections and maintenance are necessary to ensure that the rails remain in optimal condition to handle the dynamic loads imposed by crane operations. In Saudi Arabia, where temperatures can reach extreme highs, the QU120 is designed to perform under such demanding conditions without compromising its structural integrity.

In summary, Saudi Arabia QU120 crane rail is a critical component of industrial framework, providing a reliable and durable solution for supporting heavy crane operations. Its robust design and compatibility with international standards make it a key player in the country’s ongoing industrial expansion and development. As Saudi Arabia continues to grow and diversify its economy, the QU120 crane rail will undoubtedly play a significant role in the construction and manufacturing landscapes.

We can supply the international standard flat bottom rails as below:

If you need anyone, please feel free to contact us.